|

Cheers, think im going the bike engine route, but im going to get it painted after im finished building so if i have to change things it wont mater so much

|

Try ebay for a column, or your local scrap yards.

That's a very clean garage! TT |

Quote:

Haha thanks, that's my garage, I do all my fabricating in my workshop at the bottom of my garden! |

|

I don't no why but I have the latest book with the new 10mm longer wishbones but the jig drawings look like they haven't been changed, so I had made my jigs to that, then when I had made a wishbone and checked the bush centres they were 10mm short, to say I was unhappy was an understatement, I can't believe there's nothing on the amendments page just to give you a heads up, I think i will get away with it as I have wound my rod ends out 5mm and I might skim 5mm off the matting face on the stub axle or put a spacer behind the hub, so a std driveshaft fits The rod ends are still in the tube insert a full 1" and they are only threaded that much so that's ok, just didn't really want them wound out to far    |

|

Quality !;)

|

Very tidy indeed, keep it up mate

|

nice work and good progress, keep the pics coming :)

|

|

|

|

|

after sleeping on this a couple of nights, im going to remake the rear wishbones so the rod ends are straight, and have a bend in the side tubes, its not because of the angle its more to do with the clearance either side of the hub, as when you wind the joints in and out the gap changes, also they could do with being 5mm longer to suit std drive shafts, as the jig drawing in the book was wrong

|

Well got a bit of time on my mk2 rear wishbones today, decided against the bend so notched them on the angle instead

I'm thinking about putting a tube here, notched round the two  And a tube at the back, obviously longer  These tubes are 25mm diameter, does anyone think I need a diagonal, I could use 19mm tube, just trying to keep the weight down, I have seen rear wishbones with no diagonals just two cross bars like in my pictures |

|

|

Those new arms look really good mate. Like the engine too.

|

Cheers for the comments!

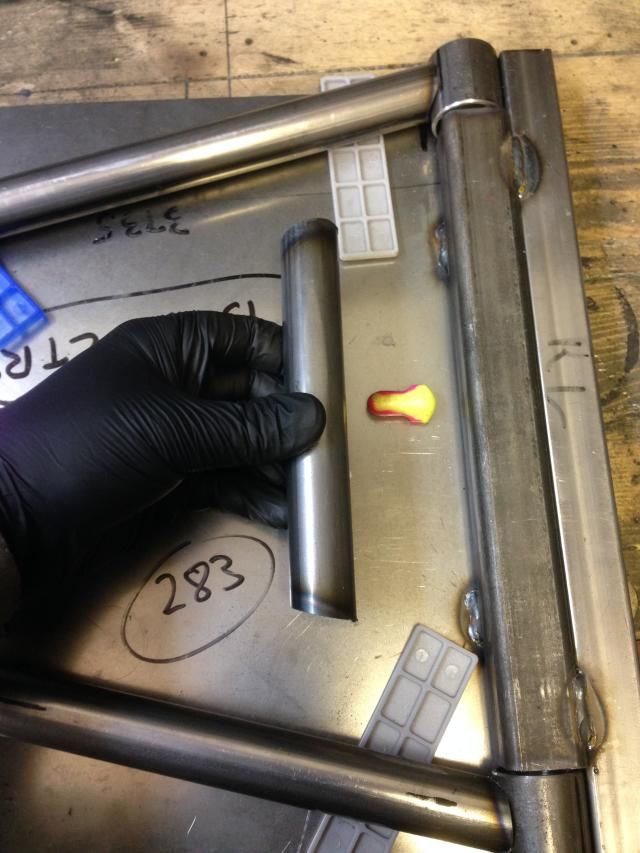

Sat down with my bike loom and labeled every plug using the wiring diagram to work out what's what I think I'm going to use the bike loom as a base and extend and alter it to suit    Oh how I love my label machine! Also my mate gave me a hoist, it was filthy so gave it a good clean and re grease, also shortend the loop chain from about 4 meters to a small hoop  |

Whens the divorce ?:o

|

Quote:

|

|

|

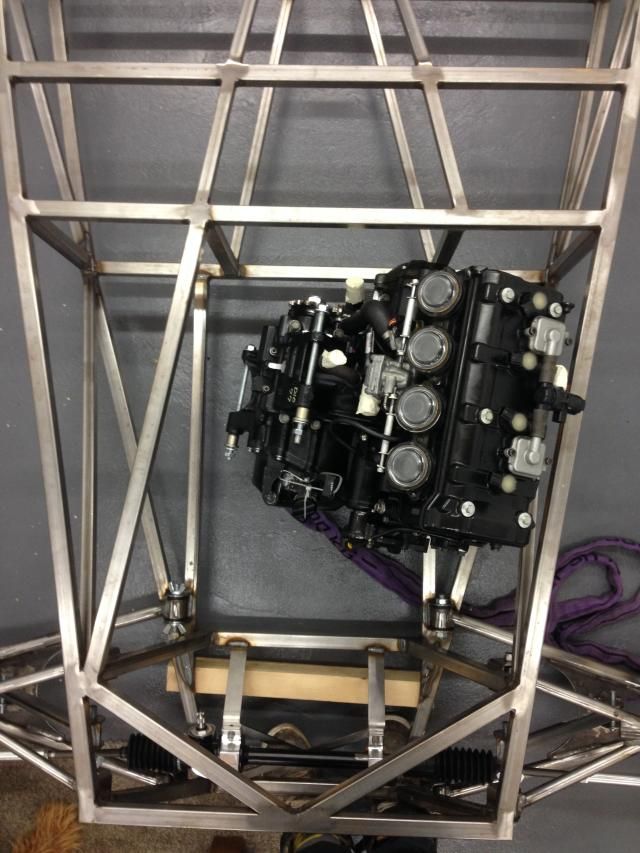

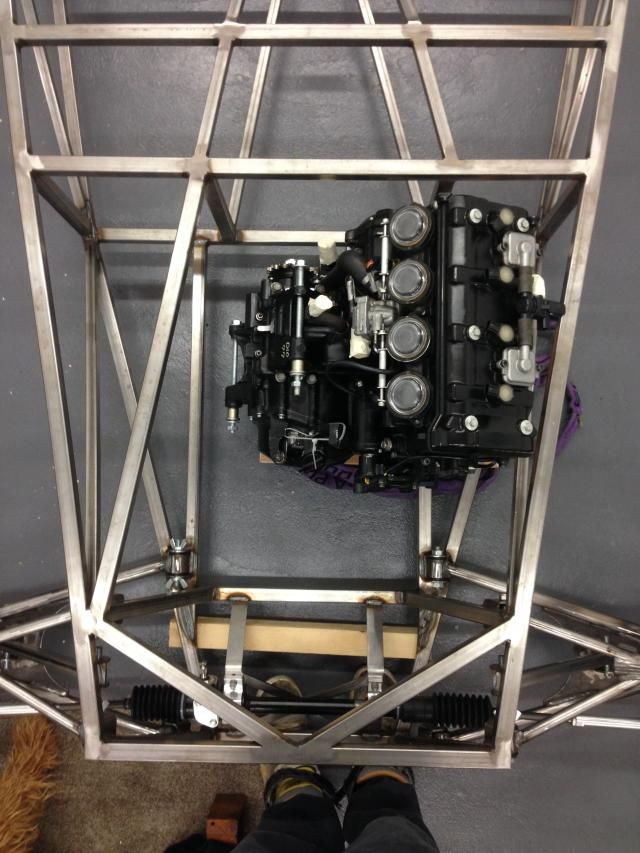

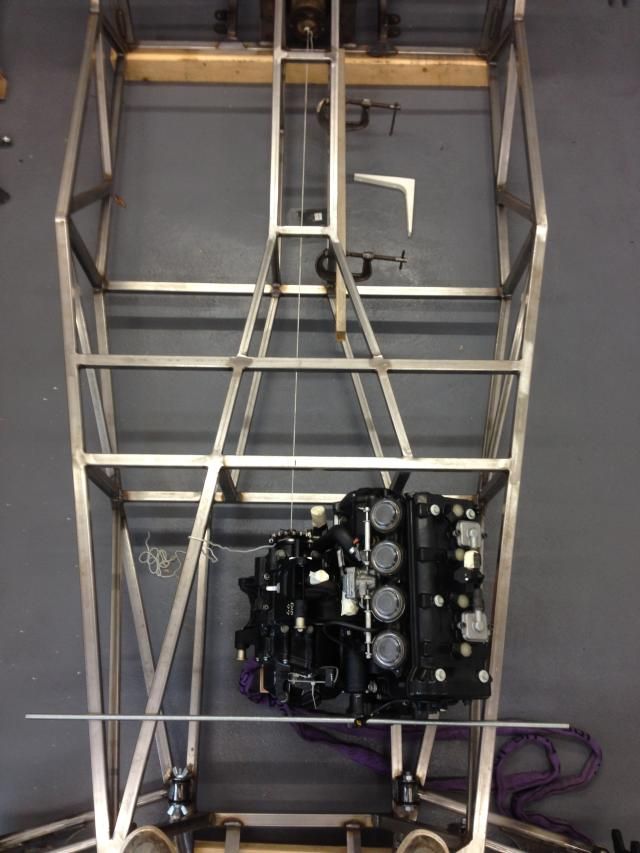

I can rase the car up or down to alter the mounting height, I'm just waiting to hear back from AB performance on his zx10 sump height, I'm hoping to have the underside of the sump flush with the underside of the car

I need to decide on position next, from the pictures I've seen most seem to be mounted towards the rear of the engine bay But some seem to be straight and some to be on an angle parallel with the side rail, on reading it looks like the output flange and the diff flange are supposed to be parallel, if anyone could help out that would be great   Thanks for looking |

When I had a bike engine in mine it was parallel with the Centre line of the car like your 2nd picture and everything worked as it should. If I remember correctly when the car was corner weighted it was 520 kg with a full tank so there's a benchmark for you.

I'm running S2000 power now though and I much prefer the nature of a car engine but horses for courses and all that :D |

Ross you want the input and output flange to be as close to parallel as you can to prevent any vibration. When setting the height/offset of the engine you just need to make sure you don't go above 7 deg on each universal joint otherwise you run the risk of shortening the lifespan of the bearings. The smaller the angle the better though.

It's not the be all and end all if they aren't parallel/coaxial and you end up running different angles on both UJ's, it will just introduce more vibration into the system which essentially being a race car you won't really notice. If you were designing a tin top designed to cruise along the motorway at high speed you really don't want to feel that vibration. If you have a look at the shaft drive Triumphs you will see that only has 1 UJ meaning there isn't a second UJ to cancel out the speed variation and therefore the vibration in the system. And the rear wheel pivots the angle of the joint changes meaning the vibration in the system increases. So don't get too hung up on trying to get it spot on. |

Quote:

|

Quote:

|

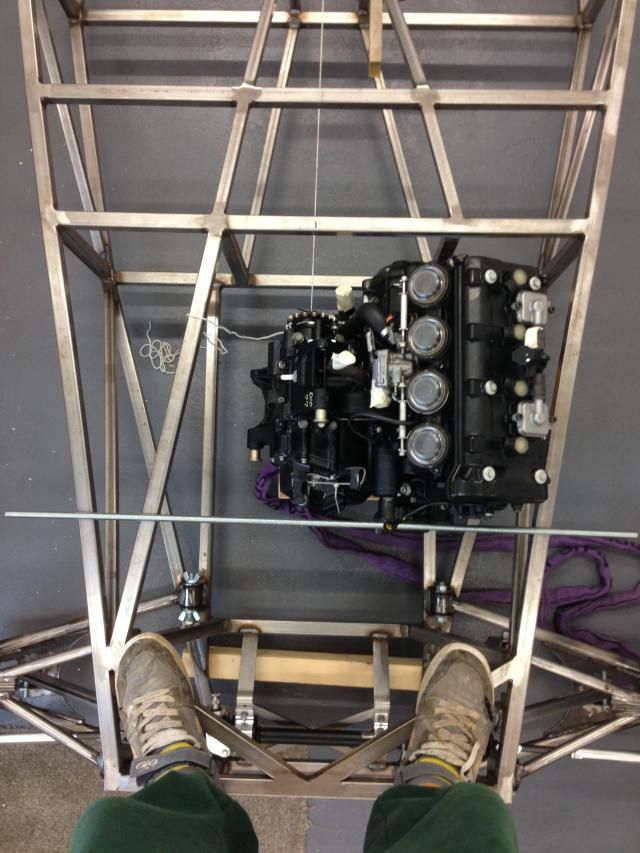

Just been looking at engine position and I'm sort of happy with this current position

Running the engine dead inline it seems to put the output shaft in a good position If I turn the engine so it's parallel to the outer chassis rail it just skews the output shaft but doesn't improve the position for the prop And from what I've read it's better for the flanges to be parallel     In this position the total prop length would be 1460mm but I could move the engine back 50mm if I moved the passenger footwell upright back I have strung a ling between and it's at an angle from the horizontal of about 4 deg, I take it I will still need a 2 piece prop with a centre bearing and a slight kink in the centre so the UJ's aren't running straight |

|

Argument was about angle of u/j's in the prop but you would need a center bearing anyway.

|

Ross you can just use a 2 UJ prop setup with the UJ's 90 degrees out of phase, no need for a centre bearing. You only tend to use a centre bearing when you have 3 UJ's in the proshaft as you need the centre bearing to support the centre UJ otherwise it would be free move in free space.

|

Quote:

|

Quote:

|

|

|

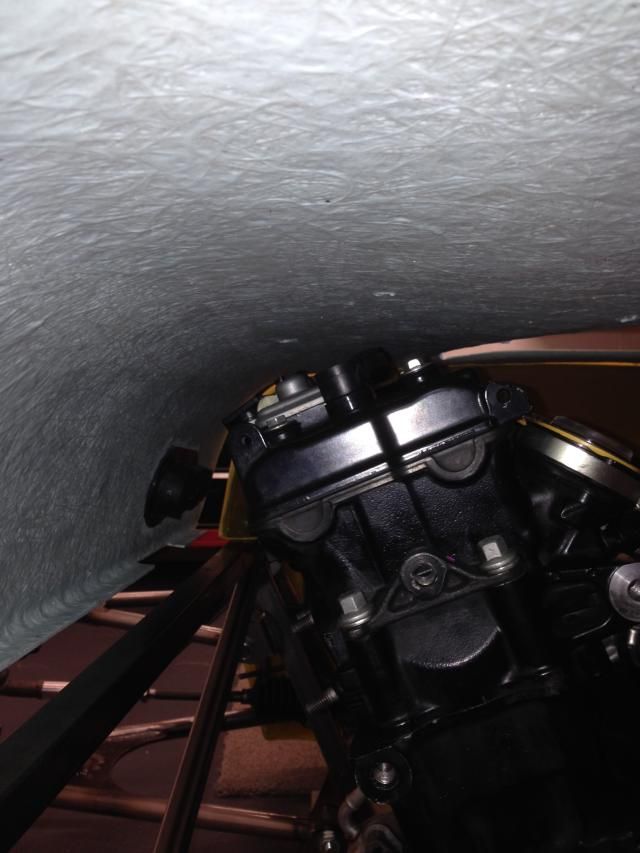

Think I've got clearance around everything that I need to have

So Tatley off the haynes forum who lives not to far from me has kindly lent me his body work so I can mock things up  Looking a bit like a car!  There's a bit of clearance over the top, this is saturn body work but I'm holding that the exquinox may be has a bit more |

Quote:

|

Quote:

|

| All times are GMT +1. The time now is 06:13 PM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2024, Jelsoft Enterprises Ltd.