|

Hi,

Have look here: www.haynes.co.uk/forums/showthread.php?t=13563 I just published 3D drawings of all the bodywork from Equinox with measurements in agreement with Dave @ Equinox Products. Hope this can help you to mock-up :) Good luck. |

Quote:

|

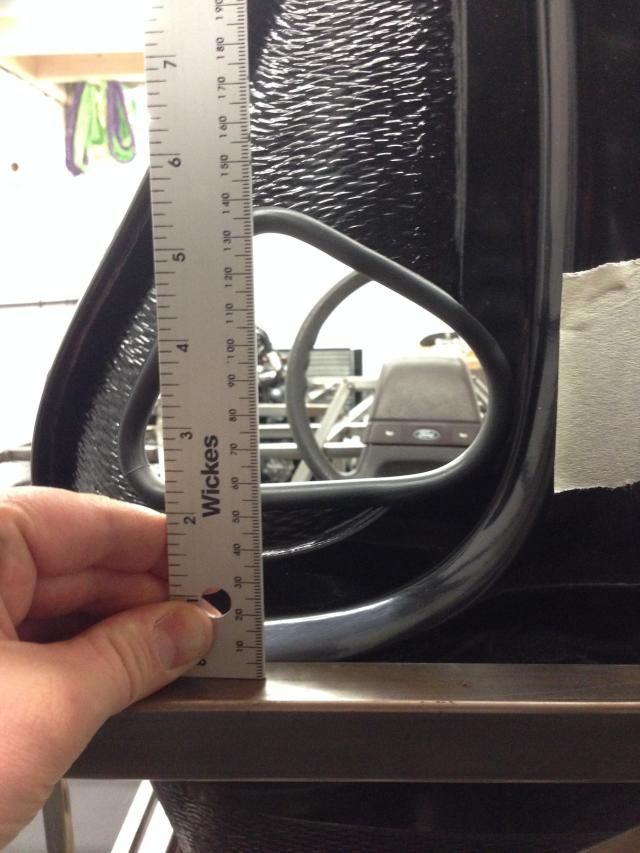

Pics didn't come out so well - but I did get some measurements - taken from the Equinox scuttle front edge and the nosecone back edge (i.e. each end of where the bonnet will sit). I'd say that as a minimum you've got 260mm clearance at the scuttle end (above the level of the top chassis rails) and 200mm at the nosecone end. The Equinox nosecone comes back to just about where your left foot ends in the pic earlier on this thread - i.e. just behind where the triangulation is at the front of the chassis.

|

Forgot to mention, those measurements were from roughly the centre of the chassis - both the nosecone and the scuttle are quite flat topped with relatively steep sides compared to some other 7-type bodywork.

|

Before you go to far think about oil surge and how to stop it.the engine is not meant to run fitted in the frame that way so the oil will run away from the pick up.

Could save you plenty hassle ;) |

Quote:

|

|

Looking good so far.

Don't forget space for a fan between the rad core and front frame. I did! |

Quote:

|

|

|

I decided to rubber mount my engine cradle, so have used some spare wishbone bushes I had left, I will see what it's like but could

Always make some softer bushes if I need to  Struggling for bolts, hence the washers, there m10x1.25 so not really very comon  I'm going to weld spacer tubes In between the plates   |

|

That's some real tidy work there, looks fantastic.

|

|

|

|

|

|

|

I just need to decide where I'm going to T my header tank into and make a few brackets to support the tube in places to stop the silicone rubbing anywhere!

|

|

|

You may want to add some sort of ridge to the pipe ends if you have not already done so,two builders were scalded when the pipes blew off when hot due to not gripping the pipe.

|

I think you might find that they were also using plastic fittings from a vacuum cleaner

Arfon |

|

|

Here's a pic of where my upper harness holes fall, there a bit high up  i iI was hoping to have some welded bosses in the top chassis rail like most people do must looks a bit high, I don't really want a cross rail as I'm going to put A diagonal across the rear hoop, what options do I have, anyone got any ideas? |

Looking good there, sure someone will come back with a bright idea about the harnesses......I may well be wrong but I was under the impression that the steering lock was one of the things required for iva?

Russ |

You don't have to have a steering lock for IVA but you do need 2 forms of security. Just fit a key/ keyless ignition and an immobliser. That's why the ignition barrel and steering lock was handy.

|

Quote:

Quote:

|

Ah cool, that's good then :D

|

|

|

|

Great build so far mate, nice clean look. Good motivation for me to pull my finger out

|

Quote:

|

|

|

| All times are GMT +1. The time now is 05:40 PM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2024, Jelsoft Enterprises Ltd.