|

Body/floor/interior rivets and rivnuts

Hi,

I'm going to get my chassis back from the sandblasting/powder coating at the end of the week. I will soon put the floor, interior panels, and I am also going to receive my body kit from Equinox some day this week. My floor will be made out of 3mm thick aluminium, inside panels out of 1.2mm thick aluminium. Thickness of my tube walls is 2mm. I was wondering what kind of rivets do I need to buy : diameter? length? Are aluminium rivets OK? The books says 3mm rivets for the inside panels and body elements, at 50mm spacing. Do you think this is OK? And will this rivets spacing and diameter be OK for fitting my aluminium floor too (3mm rivets sounds a bit small to me)? also, where did you use Rivnuts to be able to remove the panel? If you guys would like to share your experiences about that, and give me good advices, I would be glad :) Thanks a lot. |

What ever you decide and 3mm 1/8 are ok,still use Sikaflex/PU to glue it to the chassis.

I did this and used plenty of rivets and the car is raced and no problems,consider placing you seats on a strip of steel across floor and fixed to outer and trans tunnel rails for piece of mind and you wont find your undercarriage dragging along the road.;) |

I used 3.2mm sealed rivets for the floor and a hell of a lot of them.

I also riveted the transmission tunnel sides and the top above the gearbox. I used 5mm rivnuts for the transmission tunnel top. I used 6mm rivnuts for the side panels, scuttle, nosecone rear tub and arches. My only annoyance with the sealed rivets (the ones I bought) is that they left a 4mm long spike sticking up as the break point wasnt at the top of the rivet. You don't realise how many times you take the bodywork off. I tired to leave the riveted panels to last but I still had to take one off again as I had an oil leak on the propshaft seal. HTH |

I used 3 mm Ali floor I used sikaflex 3/16 or 4.8mm rivets at 50mm pitch which where sealed and steel rivets for strength remember if you do you steel rivets on Ali you will need to put a blob of sealer or paint or something as the steel and Ali will react together. I did use countersunk rivets where the side panels fit and I am glad I did as the side panels where tight

|

My floor, Trans sides and seat back are rivited. All other panels are designed to be removeable.

Floor was rivets and FSS ( F.....g Sticky Stuff ) TT |

|

Has anyone used self tappings screws instead of rivets?.

Is there any reason why self tappers can't be used?. I was thinking of using them cheaper than rivnuts and could be removed afterwards if required. Regards Mick. |

I would worry about them rattling loose, especially for the floor. There is no reason to remove the floor, so they provide no benefit there. You can use them for interior panels, but rivnuts seem like a sounder choice to me. Although they are pretty expensive and time-consuming to install.

|

Hi,

Thanks to all of you for the replies and very useful informations. I now have a very nice smooth black powder coated chassis, and also received the body kit from Equinox. As it has been said here before, the quality is very good. So, I think I will go for 3mm rivets for the floor, 50mm spacing, same for the trans side panels and back seat panel. And, I don't look forward to this, but I will fit all the body kit elements with rivnuts, as most of you say that it has to be easily removable. As well as the top gearbox and propshaft covers. Question: for the floor, should I use steel rivets (aluminium will be too weak?) I'm sure I will have further questions when I start :p Thank you very much. |

I would worry about steel rivets rusting as they aren't painted etc. Aluminium rivets are plenty strong enough, they are used in planes! Make sure you use closed end rivets

I don't like rivnuts, they have a horrible tendency of spinning with the bolt still in them :( I ended up tacking the rivnuts to my chassis where they hold the nosecone on. The only other body part held on with them is the scuttle. |

If you saw how planes are put together with rivets you would not get in one but I still do,need help obviously !

|

Something along the lines of this?

|

Quote:

Also, I installed all of them without the special tool. I used a long M6 bolt with a nut on it, some washers, and a steel strip with a hole in it. I would thread the nut, washers, plate and rivnut on the bolt, insert the rivnut into its hole, clamp the plate to the chassis, then tighten the nut holding the bolt steady. The thread of 8.8 bolts and nuts would hold for installing 3-4 rivnuts before stripping, but that's ok. A stronger bolt would probably help. |

Exactly Steve cleco heaven,but they use proper "rivets" .;)

|

Hi,

Now that I have cut the floor, I can come back on this thread. I marked the drilling points on the ally plate, and it is clamped to the chassis. But I was wondering, what is the right order ? - drill - unclamp - Sikaflex - rivets or : - Sikaflex - clamp - drill - rivets Thank you. |

Hi, Drill all holes -unclamp- sikaflex- rivet, Cleco's are also very handy locating panels while drilling and fixing. Cheers Brendan.

|

You don't find many rivets in a wing it's 99.99% bolts.

Arfon |

You are joking of course:confused: rivets are used extensively throughout most aircraft both wing and fuz unless of course you are talking about composites and very modern aircraft .....if you are not joking then where do you get that figure from:confused:

|

Option 1..

|

Only bolts in the wing hold spar to fuselage and elevator to wing and also

flaps,boatload of cherry rivets hold the important bits on.:eek: |

If you want to be accurate, large civil airliners have their wings held together with interference fit "bolts". Smaller aircraft use Rivets & composites use bolts & glue!!

Hope that helps |

Cirrus SR 22 is plastic !

I think you mean what holds the wings on,they are still riveted together. A lot have "Jesus bolts". Jesus is that what holds that on. |

I can assure you that large aircraft wings are held together with interference fit bolts, they are hammered in & have nuts put on the reverse side to a set torque. Having worked on the A380 wings I think I can assure you this is correct!

|

Grob use a method of a spring loaded ball bearing in a tube to stop the wings falling off their de-riggable aircrage. ie sailplanes. It makes the easy to take apart if you end up landing in a field but always at the back of your mind when spinning

|

Hi,

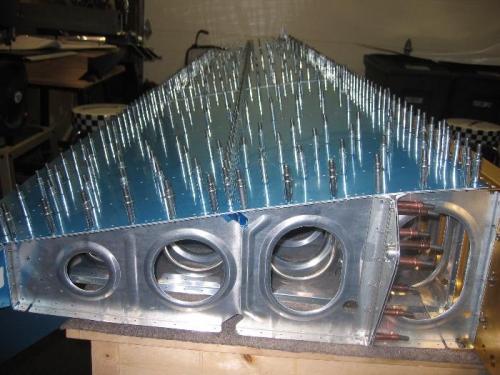

Thank you very much for the tips and help... and the very good informations about how to make an airplane wing, it will be very useful if my next build is a DIY plane :-D ! So, I managed to fit my ally floor. 4mm aluminium rivets, 1 every 45mm, with a blob of sikaflex on each of them. Sikaflex on all the rails, including the 2 seat transversal rails.  2014-03-14_16-57-32 par Voucht71, sur Flickr It may have cost me a bit of money, but I'm very glad I bought a rivet air-gun and also (as I'm a very very lazy guy) and air sikaflex pump! Both of them worked a treat, and automatic tools were very welcome after I drilled all these holes ! A shame this air gun does not work with rivnuts!  2014-03-13_10-36-38 par Voucht71, sur Flickr  2014-03-13_11-29-42 par Voucht71, sur Flickr  2014-03-14_18-15-36 par Voucht71, sur Flickr Tomorrow, I am going to put the chassis the right way around, and start to reassemble everything, starting with the engine and transmission. |

Quote:

I'm inclined to do similar to you, how many rivnuts did you use for the side panels. And did you drill out your 3mm floor (I have 3mm alu for the floor too) to fit the rivnuts flush with the floor panel? I had a look at your blog but my French is not good enough!!! |

Quote:

Anyway, here are my answers to your questions: Floor : I actually used rivets and not rivnuts for the floor, because I can't see why I would need to remove it, as I kept the transmission tunnel open, so I have access to the propshaft from underneath. So I used 4mm rivets every 50mm along each edge. I also sealed/glued with Sikaflex. Side panels : all the bodywork I wanted removable. So I used M5 rivnuts, countersunk head. Top side : 3 under the hood (the one in the very front is also the nose cone fitting point) 2 under the scuttle 2 between the scuttle and the rear arch None on the arch, but the rear part of the side panel is attached to the chassis with the rear wheel arches. So it is 7 fitting points + 2 or 3 with the rear wheel arches Underside : 5 on the front part (in front of the angle) 2 on the rear part (behind the angle) So it is 7 as well So 14 rivnuts per side panel. Hope that help. Do not hesitate to ask if you need :) Good luck! |

I just realized that I might have misunderstood your question.

You were asking about the rivnuts to fit the side panels through the ally floor. Sorry :o Quote:

The link to my blog about that is: http://vouchtroadster.blogspot.fr/20...panels-09.html (I moved the "Translate" button on top of the side bar so it is easier to find.) There are 4 rivnuts fitted through the floor (+ 3 directly on the tube, at the front of the chassis) Also, these countersunk rivnuts I used to fit my side panels are M6 (9mm hole) and not M5 (7mm hole) as I said yesterday. I hope I have now answered your question :) |

Merci beaucoup for taking the time with a comprehensive answer, much appreciated! I'll take a much closer look through your blog now, the photo's you've got on there are very helpful. Although I am hoping that I do not have the mysterious gaps in bodywork I suspect I may have similar challeneges ahead, as my bodywork has been waiting to be fitted for nearly 3 years now and may have adopted some new shapes...!

|

| All times are GMT +1. The time now is 02:55 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2024, Jelsoft Enterprises Ltd.