|

A build update... with a few Q's

Though id put in a build update as i don't seem to have really done so properly in a while. Ill put up some pics tomorrow as well.

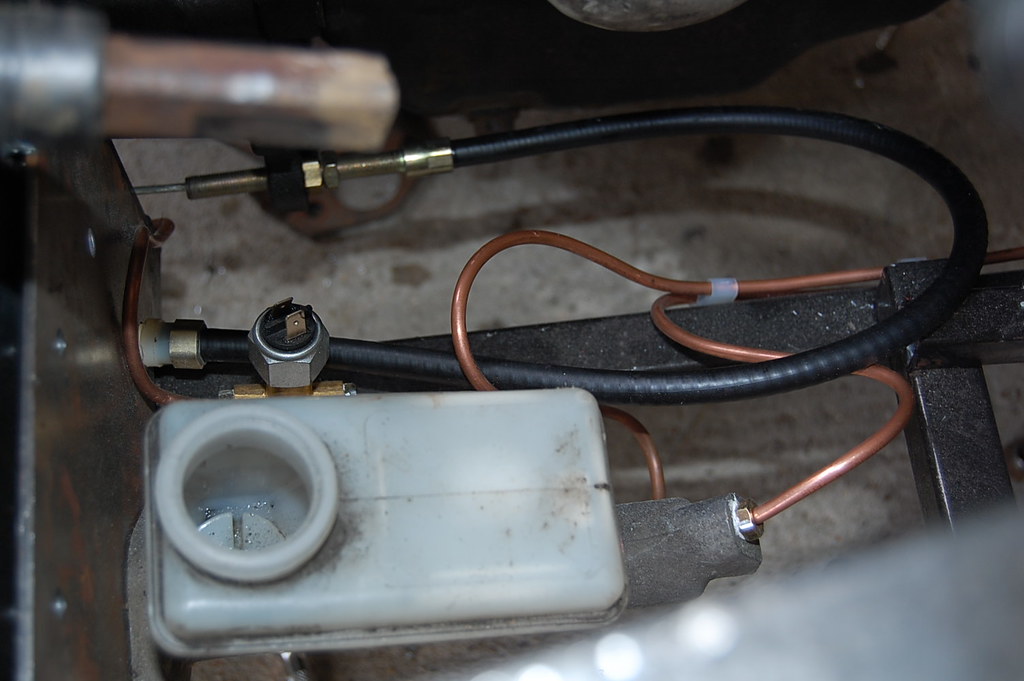

I have now got a fully fitted engine, not fitted the exhaust system but Ive made most of it including a crude 4-2-1 manifold out of steel(doesn't look great). I have done the engine electrics properly now. one thing i am unsure about is clutch and throttle cables, i seem to have lost both of them, so will end up buying them anyway. What should i be getting for the roadster, as the sierra ones are too long? I have also now got a fuel tank fitted(almost), and have done flexi fuel lines at the rear section as i wasnt able to bend the 8mm copper tubing properly at the rear. In terms of electric i haven't started on a lighting loom yet, but i should get onto that in a week or so. On Friday i jacked up the rear and gave the wheels a good spin to check my prop wasn't causing much vibration at the moment, but the entire engine started shaking. What seems to be the problem isn't the prop, the box and diff aren't entirety in line, so im going to slot the diff mount holes so i can adjust the diffs position, as it isn't too far off being in line with the gearbox. My brakes are done, except i need to buy some braided hoses to go to the wheels, should i just get these from local motor factor? I have also started to get the bodywork on, and have cut suitable holes in the side panels, and have mock fitted the nosecone. One thing i wasn't sure about is how often i should secure the side panels with riv-nuts or rivets? I should add i'm glad i picked orange, looks great!!!!:D last thing i'm unsure about is the coolant system, how is all the plumbing done on the 1.8 cvh, as there seem to be numerous connector on the engine block and i'm not sure how to do it all.? Thanks! :) edit: i remembered i took a few pics last weeks, ill add some more tomorrow:   I should also say, held the rear tub in position on the car, and can safely say it wont fit in my garage with the rear tub on as without it on it is already touching the garage door at the back, so ill be leaving that till as close to the end as possible. |

Looking awesome considerign your youthfulness.... Are yuo getting any help with it?

TT |

Quote:

|

Well untill your "need a car" post the other day I would not have guessed.

Your gona turn lots of heads in a couple of years ;) I learn ed everything myself over the last 18 years of car ownership... ;) TT |

Nice work Geeman

Your build is looking great :)

Looks like you are making some steady progress :) Here's a clutch cable that many of us are using ( Myself included ) .... Good price too Capri Clutch cable Nice and short, does the job a treat. Not too sure about the throttle cable .... Not got that far yet :o I guess once I am ready for that, i'll pop down the motor factors & buy one of those universal type cables then make it up to suit the car. Flexi Pipes. Again not got to this stage yet .... When I am ready i'll work out wich way I want to route them, measure up & get some to suit. If you post a picture of your engine & radiator in situ, I am sure that someone will be good enough to knock up a drawing of the coolant hose layout for you ;) Well done on your progress. |

a few pics:

|

Well done Geeman, that's looking great......;)

Looks like you've got some nice sticky tyres to go on aswell. Nice colour but i think i've seen that much orange i shall have to be buried in an orange coffin..:o Keep up the good work, you'll soon be on the road. AndyH |

Rest assured, when I order my glass it wont be in orange..

TT |

How did you end up attatching the rear tub and also the rear arches as there was no answer in your other post.

|

Quote:

as for the arches... anyone got a suggestion as to how i should fit them? |

I belive most people glue 'em! Sikaflex i think its called...

Jas |

Quote:

|

Nice lookinjg job, keep up the good work.:)

|

Quote:

TT |

what version of sikaflex should i be using as there seem to be hundreds?? it seems like it'll either be 221 or 252?

|

|

Quote:

|

Quote:

|

Clutch problem...

ok, ive got the clutch cable in, however, i am not able to push the pedal in, the clutch arm seems to be stuck,its not hitting the chassis, theres enough room for it, it has about 3 cm of play in in, then it doesn't move at all, i dont want to apply excessive force and break it... the clutch hasnt been used for about 6 months, what could be the reasons for it not moving, the only thing i could think of is i nay have hit the lever on something while the engine/box wasn't in.. any suggestions??

|

Is the leaver free from obstructions?

Sounds like the release bearing may be stuck on the input shaft. TT |

Quote:

The bit circled in red can move on the shaft aboud 2-3 cm easily  |

Quote:

Could just use 4mm bolts with washers and butterfly nuts and get some nice edge trim from cbs: http://www.cbsonline.co.uk/rubber-p-...pi2-3527-p.asp works a treat and finishes it off nice. AndyH |

Got my sealent today. nice and quick :)

I will be bolting my arches on. TT |

Quote:

|

|

ok, is there any reason a clutch release bearing would freeze up after no use? ill split the box/ and engine some time soon and see what the problem is?

|

ok, engine and box are split, clutch is out, but.. i have no idea what could be wrong.. here are the pictures. The clutch arm is able to move freely in the bellhousing, whats wrong.. and what do i need to fix it.

|

Its obviously hard to tell just looking at photos. My clutch has no play in it when its setup, all the slack is taken out. When your clutch fork stops / jams. How much space is left in the opening on the bellhousing.

|

Quote:

i know this is a stupid question, but when to move the fork to operate the clutch, it is pushing the springy bit in the second pic in my previous post? |

It may sound obviuos but have you double checked the clutch pedal end of things ??

With the cable engaged in the pedal but not to the gearbox, it may be worth checking that the pedal & inner cable are free to move enough to give you the desired amount of travel :) Also worth checking the cable routing .... If you have a very sharp kink in it, it'll be very difficult to depress the pedal .... The cable will be wanting to fold in half, rather than pulling the inner cable through the outer sleve ;) As said very difficut to diagnose the problem without seeing things in person. |

Quote:

i wonder, when the fork moves forward, what happens, as i dont see how the clutch is meant to work. also i remembered this cable from somewhere.. is it for anything...:   |

That cable your speedo drive cable from the gearbox.

With regards to the clutch operation. The clutch fork pushes the clutch release bearing into the clutch cover plate (AKA the springy bit :D ) The depressed cover plate then takes the pressure off the clutch friction plate, so now the engine is no longer connected to the gearbox and both are free to rotate at independent speeds. |

Yep that cable is the speedo one & will have nothing to doe with the clutch operation :)

Right Ho .... Here's a brief insight into how the cluch works You have a friction plate that sits against the flywheel the central part is fitted via the input shaft of the gearbox. This is held in place by a sprung loaded clutch cover .... Thus trapping the friction plate against the flywheel & providing drive from the engine to the gearbox. You have said when you press the pedal, the release bearing makes contact with with the clutch covers spring fingers ..... This is normal .... The lever now needs to move a little further forward & will diss-engage the friction plate. When the fingers on the clutch cover are depressed it releases the pressure on the friction plate, this in turn is free to spin & will stop the engine driving the gearbox . I don't expect you have ..... Make sure you have put the friction plate the right way against the flywheel The flat side of the friction plate must face the flywheel ;) If the release bearing is free to move on the input shaft, it may be a case of exerting a bit more pressure on the pedal to see what happens !! |

Quote:

|

ok.. sorted... well kinda, i got it to push down, with alot of force, but i dont think i could keep this up as the pedal feels as if its bending. Ill probably make another one out of some 5mm steel.

|

I'd have a good look around the pedal box as it sounds like you have some flex somewhere. I'm using a stronger FWD clutch cover plate thats kinda like off / on. The book pedal and pedal box is plenty strong enough when bolted in correctly.

|

Quote:

Anyway, ive finished the handbrake as the screw on nipple came today, and it worked perfectly. I also received my sikaflex today, and glued the left rear arch on. however it seemed kinda messy as a bit of the sealent is visible on the outside, so i think im just gonna rivet the other one on, infact i ended up riveting the left one anyway so the sealant can set. |

piccies:

rear arch fitted:  rivets inside rear arch(will redo with washers later)  handbrake nipple in situ  |

more rear arch:

brake pedal piston thing:  some sikaflex(well sikafles like stuff). Is stifs to my hands like anything and even after 2 thorough scrubbing with swarfega its not even beginning to come off my hands.  a MAJOR mess:  |

more mess:

there just isnt enough space for me to move anymore.....:rolleyes: |

| All times are GMT +1. The time now is 07:26 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2024, Jelsoft Enterprises Ltd.