Quote:

Originally Posted by alga

I have standard book design wing stays. They've broken at the weld seam between the tube and the steel band 3 or 4 times. Each time I just redid the weld and promissed myself to build sturdier ones soon.

http://locost.lt/download/file.php?id=818&mode=view

Sylvain, so how are your new ones different from standard? Thicker plates? |

I have used 5mm strips instead of 3mm for WS4,5,6, and my WS5/WS6 assy is in 1 piece.

2015-04-26_10-10-25

2015-04-26_10-10-25 by

Voucht71, sur Flickr

As the books recommends, I also made a "t" cut on the strip, so they go into the round tube, and they don't "pull" on the weld: the strips are naturally blocked in position into the tube, the welds just maintain them in place.

2015-04-25_10-18-37

2015-04-25_10-18-37 by

Voucht71, sur Flickr

All other plates (WS1, 2, 3) are also 5mm thick, and I used 20mm tube and not 19mm, but I don't think it makes much difference.

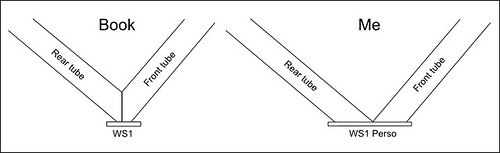

In order to make the tubes easier to place the lower plate WS1 (I couldn't go anywhere with the book's design), I made WS1 bigger and triangular, so I could place each tube independently on the plate on the right position, and each tube rests on the plate, and not against each other as on the book design.

Book_and_Me

Book_and_Me by

Voucht71, sur Flickr

It might be overkilled, but it is steady.

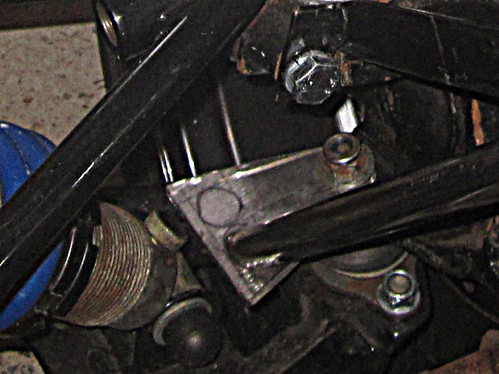

2015-04-24_11-17-41-b

2015-04-24_11-17-41-b by

Voucht71, sur Flickr