|

|

#11

|

||||

|

||||

|

Quote:

Could you post pictures of it when it is finished? I'd really like to see how it looks. Thank you.

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://cafrazx550.blogspot.com/ |

|

#12

|

||||

|

||||

|

No problem i'll take one tonight before painting.

__________________

My Blog: deannoshaynesroadster.wordpress.com (under construction) Being overtaken is a sign of weakness. South Wales Kit Car Club www.southwaleskitcarclub.co.uk WWW.HELPFORHEROES.ORG.UK XBox Gamer tag: D34NNO |

|

#13

|

||||

|

||||

|

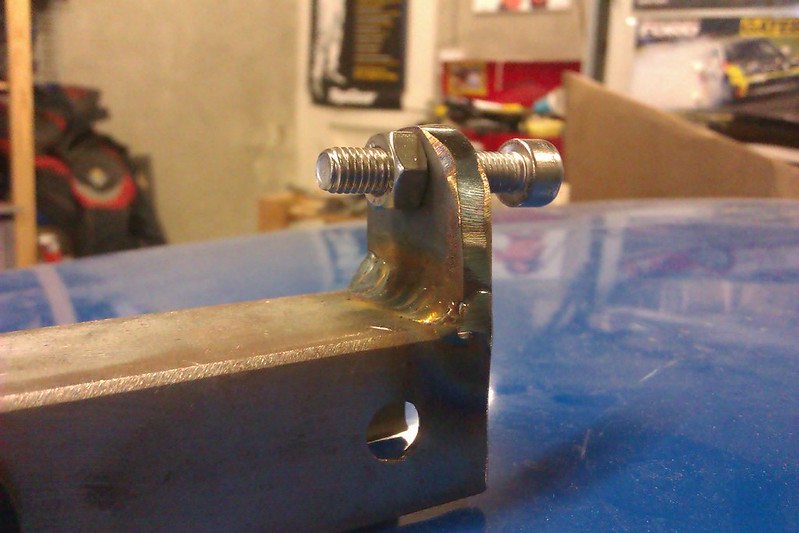

This is my New (Sylvain) Pedal Box.

I have made one modification to the design this being a piece if 25 x 25m 6mm plate with an M6 thread tapped through it 15mm from the pedal face and inline with the centre of the pedal. One half of the bush, I made these out of Nylon.  The Three pedals.  The modification.  Front View of the pedals in place.  Any feedback or your oppinions are welcome. Regards Dean

__________________

My Blog: deannoshaynesroadster.wordpress.com (under construction) Being overtaken is a sign of weakness. South Wales Kit Car Club www.southwaleskitcarclub.co.uk WWW.HELPFORHEROES.ORG.UK XBox Gamer tag: D34NNO |

|

#14

|

||||

|

||||

|

Side View of the pedals in place.

Dean

__________________

My Blog: deannoshaynesroadster.wordpress.com (under construction) Being overtaken is a sign of weakness. South Wales Kit Car Club www.southwaleskitcarclub.co.uk WWW.HELPFORHEROES.ORG.UK XBox Gamer tag: D34NNO |

|

#15

|

||||

|

||||

|

Looking great Dean  Tho, may I suggest .... To use hex headed bolts on the pivot & stop/adjusters, as , Once you have your side panels fitted its not easy getting into the footwell with TWO hands, so if hex headed bolts are used you can place a ring spanner on the head which will find a STOP so that you can either undo or adjust the actual nut, similar for the "adjuster bolts" ....as you,d need to depress the pedal to get an allen key into your current setup, would be easier to adjust if hex headed bolts were used ... IMHO of course  cheers andy |

|

#16

|

|||

|

|||

|

Quote:

Bob

__________________

When The Results Disagree With The Theory: Believe The Results And Invent A New Theory If I had two brains I,d still be a halfwit The cave http://s1116.photobucket.com/user/my...deshow/mancave The build http://www.haynes.co.uk/forums/showthread.php?t=12669 Last edited by robo : 11th July 2012 at 08:38 AM. |

|

#17

|

||||

|

||||

|

I meant to say they would be changed they were the only ones i could get that were long enough from work.

Well spotted Andy. Quote:

__________________

My Blog: deannoshaynesroadster.wordpress.com (under construction) Being overtaken is a sign of weakness. South Wales Kit Car Club www.southwaleskitcarclub.co.uk WWW.HELPFORHEROES.ORG.UK XBox Gamer tag: D34NNO |

|

| Thread Tools | |

| Display Modes | |

|

|