|

|

#1

|

||||

|

||||

|

Just thought I would share my experience and knowledge that I have acquired in the last few months all info has been gleaned from the internet. I first thought about this when I read a thread on here regarding paint inside the suspension bush tubes and the effect it might have like making insertion of the poly bushes more difficult (as they are already very tight) .....so I thought why not electroplate them, whichever metal I used would only be around 15-20 microns thick. After some investigation I chose Nickel as it can be polished to a high lustre like chrome and has very good corrosion resistance, another side effect would naturally make my roadster very individual kinda like.... my trademark.

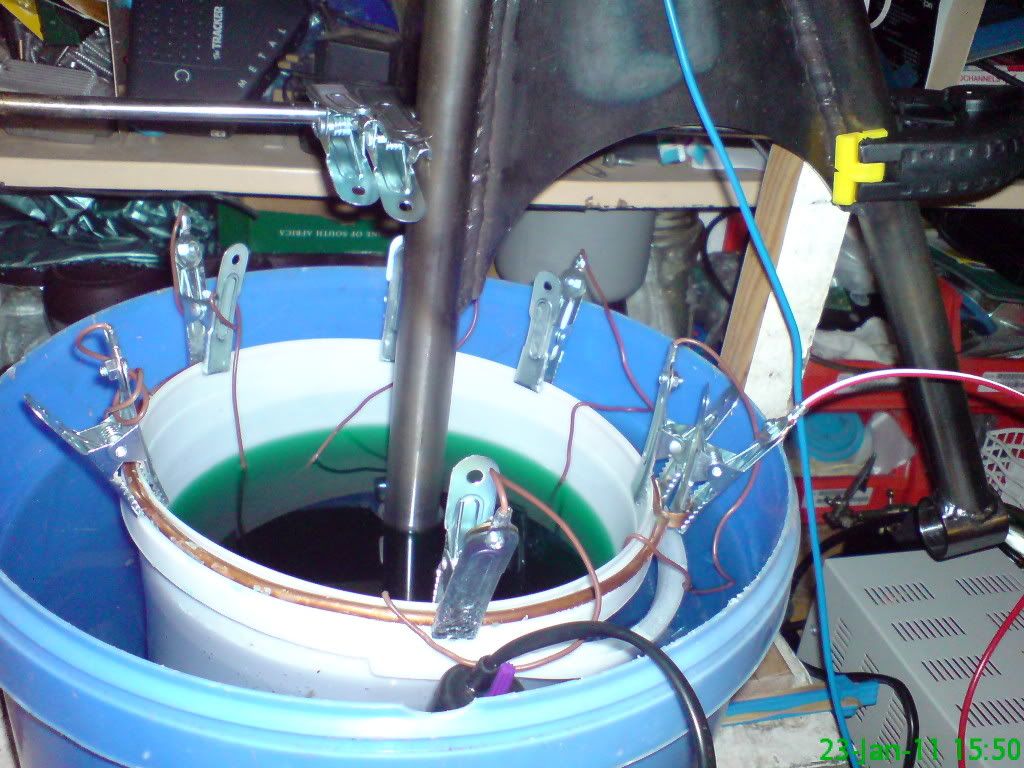

My first attempts were very hit and miss some came out good but were satin in finish and had to be vigorously polished, them some came out with black sooty deposits, them some peeled. These early experiments in Oct/Nov took me away from my chassis build, but it was something I could not leave alone, I had to stick at it. These early set ups were called Watts Baths and was about 1/2 gallon of electrolyte that consisted of 500g of Nickel sulphate salts (ebay) along with some 5% sulphuric acid to aid electron transfer, Power supply was 12 vdc car battery chargers. After a very frustrating couple of months I nearly gave up and it had a disheartening effect on the car build . As I said I could not leave alone so more intensive research on tinter, resulting in more chemicals (ebay) this time it was Nickel sulphate, Nickel chloride, Boric Acid and some sacrificial anodes made from very pure Nickel. So again I try it out and get immediate better results but still unpredictable. More research and a call to a company called Gateros plating gets me some Nickel Brighteners and maintenance but the final item was to be the most important.....a proper lab bench supply.....Why......simples I had been using a car battery charger (12v) and some crude current limiting devices and this was where I was going wrong. A chance reading on someones blog mentioned using a AA battery for some simple plating on further investigation I found that commercial electroplaters only use 1.5 to 2v dc and the surface area of the anodes should be more than the surface area to be plated (at this point I thought this is starting to get a bit heavy)......ebay to the rescue and a nice little lab supply sat next to my plating tank....oh I also found that the electrolyte works best around 30-40 celsius so a aquarium tank heater was purchased and a larger tank placed around my plating tank provided a heated water jacket. The last magic ingredient was Sodium Saccharin (yep sweetener) about 10 tablets to 5litres. Within trying a few test pieces the results were astonishing.....if the piece goes in with a highly polished surface then in comes out exactly the same except Nickel plated......so my original idea to electroplate the w/bone bushes is now a reality and anything else I wish to blingify, don't ask why but this has been a very important experience to me and has given me re-newed vigour to get on with the build so updates coming soon. Numbers for plating by the way....I found 1.5 - 2vdc and 60 - 100mah per square inch for around 20 - 25mins gives a good plate and no hydrogen or oxygen produced at the electrodes (low and slow being the motto)     Last edited by K4KEV : 30th January 2011 at 10:45 AM. |

| Thread Tools | |

| Display Modes | |

|

|