|

|

#381

|

|||

|

|||

|

Couple of things kev, First on is the ratio of master boresize vs slave boresize. The last car i converted to hydraulic clutch was a total brain ache, I had about 6 inches of pedal travel (if i wanted to keep the pedals all at the same height at rest) and struggled to find the correct ratio of pedal movement vs clutch arm movement while maintaining a clutch that was not to heavy or to light . Or one that was so light it never released the clutch and one that was to heavy to be practical for driving. Got there in the end but not after going through a dozen different combos of bore sizes. Next thing is to check that the torque movement of the lump under load wont get that slave rubbing and buzzing on the chassis. Looks like you could get a rizla trapped in there

Just thoughts Bob Edit. dont trust that plastic waste pipe kev the stuff age hardens and splits.

__________________

When The Results Disagree With The Theory: Believe The Results And Invent A New Theory If I had two brains I,d still be a halfwit The cave http://s1116.photobucket.com/user/my...deshow/mancave The build http://www.haynes.co.uk/forums/showthread.php?t=12669 Last edited by robo : 14th February 2013 at 08:39 AM. |

|

#382

|

|||

|

|||

|

There is no stopping the Man !

__________________

Cost : Little as possible. Thanks : To those who by their generosity my build has progressed. Its a handmade sports car not a flaming kit car !!! If at first you dont succeed,avoid skydiving... No parachute require to freefall,only if you want to do it twice. |

|

#383

|

||||

|

||||

|

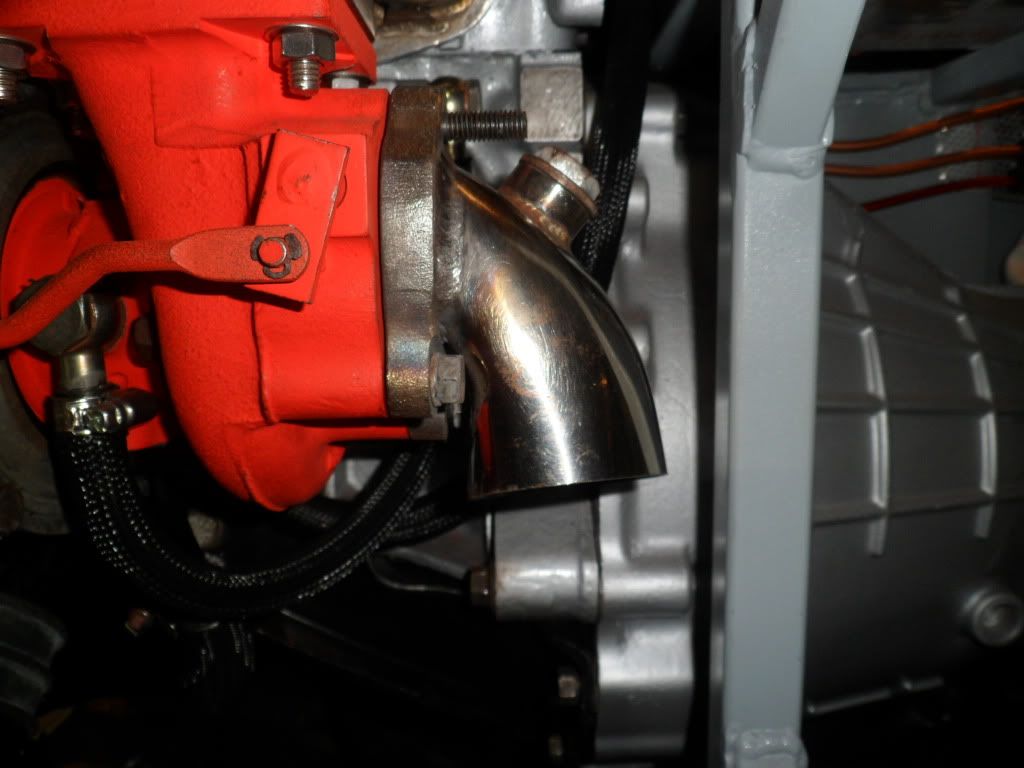

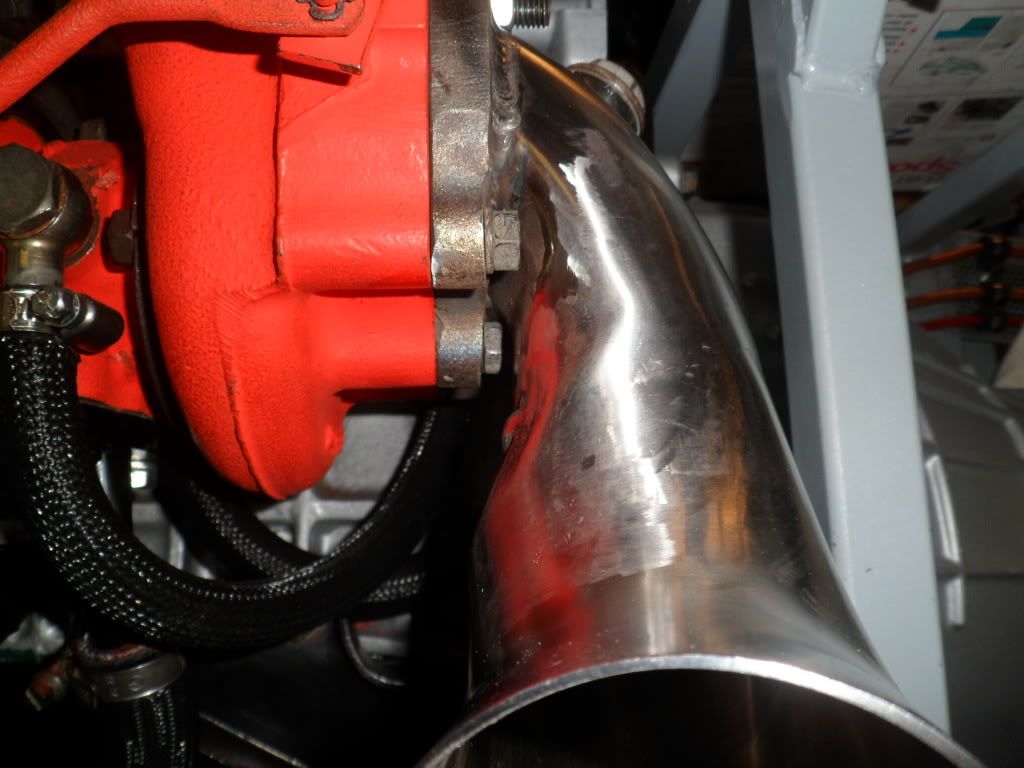

Me thinks I will cross that bridge when I get to it Bob but thanks for the heads up on it....my other headache is now solved, the turbo elbow had a wedge cut out of it and I had a bash at tigging stainless steel, I found it similar to ally except for the size of the arc which can be tiny. So now I am looking at welding on a 90 degree bend to bring it out of the side panel close to the bottom.

Here is my re-fabbed turbo elbow and first time tigging with stainless   |

|

#384

|

||||

|

||||

|

Exhaust is now coming together and I have learnt a lot about tigging stainless, and it aint as easy as I first thought.....got my 90 degree bend on and will soon fit and weld on a 3 hole flange to fit the outer exhaust pipe and silencer.....one picture is of me just offering the outer pipe up to check any clearance issues and none so far.

cut and welded up  looking from inside the car  these two lower bolt are t*ats to get at but do-able  and what it should look like  |

|

#385

|

||||

|

||||

|

Should see me finished the exhaust today.....after reading about one of Jason's failure points, I decided I was going to incorporate a decibel killer into my exhaust while I could, so I got a piece of old exhaust tube blanked off one end , then cut some slits along the pipe and then dinted the tube in on one side of the slit meaning the exhaust would momentarily have to travel backwards before going forwards again which should give a small amount of noise canceling

As you can see from the pictures it is going in before the silencer which will help even more because most decibel killers just go inside the silencer, this will be removed post IVA as I want a straight through exhaust on final tuning, the last thing I will have to do will be a rolled exhaust tip.....will be making that as well piccies as usual     |

|

#386

|

|||

|

|||

|

Nice one as usual Kev,not a criticism but something that would bug me,the sharp angle of the exhaust exit may be liable to a lot gas cutting due to high temperature gas straight from the turbo hitting the pipe.

You will understand what I am getting at,a liner at that point may be a long term solution.

__________________

Cost : Little as possible. Thanks : To those who by their generosity my build has progressed. Its a handmade sports car not a flaming kit car !!! If at first you dont succeed,avoid skydiving... No parachute require to freefall,only if you want to do it twice. |

|

#387

|

|||

|

|||

|

Jesus Kev

You don't half plod on with your build pal, how do you fit it in? |

|

#388

|

||||

|

||||

|

Quote:

Hi Will.....steady away mate steady away, although you will see some rapid progress over the coming months as I want it on the road this year  |

|

#389

|

||||

|

||||

|

After much trolling the internet and ebay last week for a tight radius rolled tip stainless exhaust end and not finding anything remotely suitable, I do what I usually do and make my own....now in doing that it means I can be different as usual. So here is a quick run down of how I made it.

First raid the scrap bin for a piece of 2" stainless exhaust pipe, then give the bit I'm using a polish up and scrape the carbon out from inside, then I give the piece a 45 degree cut then mark out the next angled cut to intersect the first one, now grabbed the first offcut and gave it a bash or two to flatten the steel, now using the 45 degree angle as a template mark out on the flat piece of steel. Now attack with angry grinder until correct shape, when that has I nice fit its back onto the tig table and weld it onto the exhaust tip grind back then polish up with a powerfile ......now to achieve the "rolled tip" I silver soldered a length of shaped brake pipe onto the exhaust exit, the following pictures will make sense of what I have just described.     |

|

#390

|

||||

|

||||

|

|

| Thread Tools | |

| Display Modes | |

|

|