|

|

#1

|

|||

|

|||

|

Hey everyone,

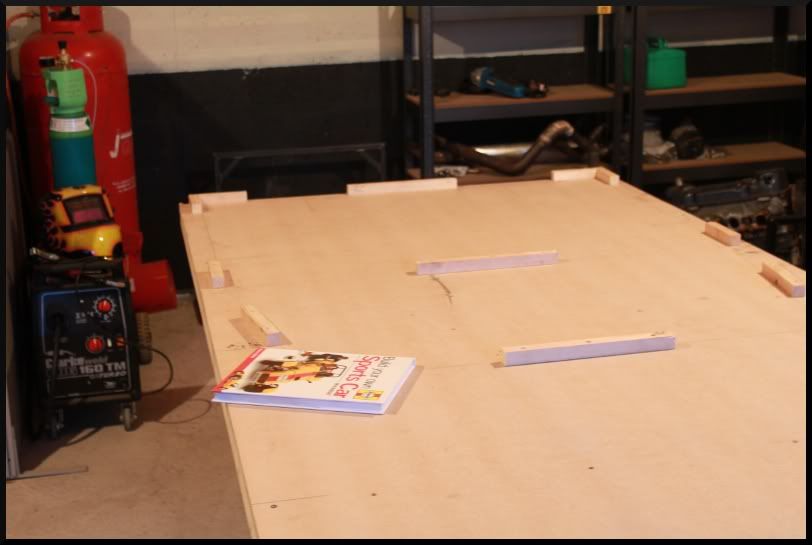

My father in-law has an old westfield (been sitting in storage for 10+ years - can see it in the photos) and I am currently stripping it down and re building it up. But when it's finished my brother-in-law will probally take ownership of it. So I came across 'The book' when searching the Haynes website for a Serria manual to strip and rebuild the 2.0L pinto powering the westfield - but decided to scrap the pinto and put in a 2.0L Zetec instead, but thats another story. well I was set on the idea of building my own car along side my In-laws westfield. I have only been welding for a few months (MIG) but I feel confident enough to have faith in my welding now (been practising like a madman). I have an engineering background but at only 25 years old don't have too much experience so I'm learning as I go along. I bought the manual and have just started the base board construction from 2440 x 1220 mm 22mm thick MDF supported by a frame of 75x50mm wood. Atm it is resting on a table but before I begin cutting metal I have 100x100mm fence posts to chop up and make proper legs with. I have a quick question regarding the choice of steel: 1) I am going to order the steel I require within the next few weeks but not sure if there is a standard of steel I require to make the chassis (mild vs meduim to high carbon content). If so what do I have to ask a supplier for? I understand that the main chassis is 25mm box 16 SWG (~1.6mm) but apart from that not a clue. Thanks for any answers and I'm sure I'll have a LOADS more questions to ask. Here are a few photos of my progress so far. Only started yesterday but worked the whole day to get this far. God this is going to be a long haul hehe. Starting to measure out the jig working to a 0.5mm tolerance: Oh and I have a habit of completely tiding my garage / tools before I close down for the night, but during work theres tools everywhere though. These photos were shot after I had tidied up. I HATE spending an hour to try and find any tools I require the next day.    I'm sure theres a few questions I still need answering before work starts properly but for now just wanted to say hello to the community. Last edited by Northern Joy : 25th April 2011 at 01:18 PM. |

|

#2

|

||||

|

||||

|

Stick your location in your profile here, its near the bottom.

You can either go 1.6mm or 2mm wall with your steel. There is not much overall weight difference. Good choice of welder, i've got the same one it should be enough to do the whole of the chassisand uprights ect. I didn't feel that my welding was up to scratch so i ended up buying the wishbones and uprights. Most importantly have fun, there will be some low points and unless you scavange or get really good bargins it will cost more than you think it will |

|

#3

|

|||

|

|||

|

that is a rather nice work space! and i love the old desk build table!

Looking forward to seeing the progress  Oh! and welcome!  Last edited by michael92 : 25th April 2011 at 01:45 PM. Reason: forgot to say hello!! |

|

#4

|

||||

|

||||

|

When you come to putting your blocks on the table it is best to put them on both sides of the material so it clamps it in place. Material can be either HRS hollow rolled section also known as black, it has rounded corners and is covered in black scale plus side is it's cheap or ERW which comes clean and bright with sharper corners but is alittle more to buy.

__________________

Website http://www.talonmotorfabrication.co.uk/ Direct email phil@talonmotorfabrication.co.uk talonmotorfabrication@gmail.com Mobile office hours 07514098334 Last edited by Talonmotorsport : 25th April 2011 at 02:08 PM. |

|

#5

|

||||

|

||||

|

Welcome Northern Joy ....always great to watch a new build and it looks like you do have a very nice workspace .....wish I could be tidy like that, I'm exactly the opposite.... are you up North?....if you are .....then you are a N.E.R.D.

(north east roadster dude) and there are now lots of us nerds in the North east especially around Teeside (north east roadster dude) and there are now lots of us nerds in the North east especially around Teeside |

|

#6

|

|||

|

|||

|

Quote:

Thanks alot, I selected the welder from reading mig-welding.co.uk and everyone seemed to rate the 160TM highly as a first MIG and so far I am very pleased with it. I am going to do the same buy the wishbones and uprights. No doubt there will be lows (like dropping the pinto on ones foot - THANK god for steel toe caps) but I sure I'll have loads more fun. Once I get the steel I'll up date this thread with my progress. I should be ok for parts as I know the guy that owns the local garage and they can get anything, I'm not kidding either hehe for very small cost. So hopefully they can help me out. Quote:

Last edited by Northern Joy : 25th April 2011 at 02:21 PM. |

|

#7

|

|||

|

|||

|

Quote:

|

|

#8

|

|||

|

|||

|

Quote:

Also thanks for the warm welcome  look forward to pestering everyone for every scrap of info. look forward to pestering everyone for every scrap of info. |

|

#9

|

||||

|

||||

|

I would say go for 2mm ERW as it's a nicer material to work with, just remember to grind a 1mm 'weld prep' (45' angle) around the edges. This will aid in the finish weld as it will give you a guide so you can see the joint,give better penetration in to the material and also means there will be some 'meat' left if you grind the weld nearly flush on the out side to fit the panels.

__________________

Website http://www.talonmotorfabrication.co.uk/ Direct email phil@talonmotorfabrication.co.uk talonmotorfabrication@gmail.com Mobile office hours 07514098334 Last edited by Talonmotorsport : 25th April 2011 at 02:27 PM. |

|

#10

|

|||

|

|||

|

Quote:

|

|

| Thread Tools | |

| Display Modes | |

|

|