|

|

#1

|

|||

|

|||

|

somebody on here was asking about a tube/pipe beading tool

the other day.. a guy(O2GF74) has posted his home made beading tool very diy but the idea can be used for bigger/smaller pipes etc its very simple and also quite clever really a simple and effective solution good man sharing it with everybody hope its of interest to somebody cheers les g PS: its under the heading .....can you see what it is yet |

|

#2

|

||||

|

||||

|

Not a bad idea is that Les

I was thinking of turning up a male & female set of rollers ( Not unlike a set of tube cutters ) in the lathe. Set them into a pair of sturdy fingers, add an adjustable clamping/pressure screw & Bob's your uncle  I had a look at some of the Pro ones .... Friggin hell, have you seen the price of em

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk |

|

#3

|

|||

|

|||

|

hi Ronnie

yes thats a good idea as well. i also thought that if you made one similar to Matey,s with a good chunky bottom bit to hold in the vice a fixed stop to hold the pipe against and the top bit heavy enough to hit/tap/beat with a hammer......... you could rotate the pipe one handed and and tap away with the hammer it could be a nifty solution if you get what i mean cheers les g |

|

#4

|

||||

|

||||

|

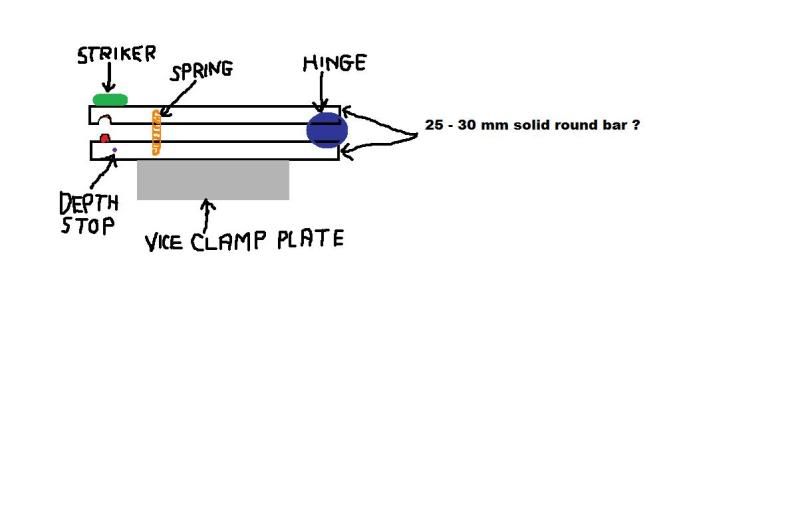

Hey Les, that's not a bad idea mate

I suppose you could fabricate a hinged anvil & dolly to clamp in the vice + a little sping to stop it bouncing ..... Probably makes no sense but you have given me a cool idea & probably persactly what you are thinking  I feel another one of my dodgy " Windows Paint " sketches coming up

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk |

|

#5

|

|||

|

|||

|

Ronnie

yes thats exactly what i mean i dont do sketches unless they are on the back of an/oil filter box lol deffo not on a computer cheers les g |

|

#6

|

|||

|

|||

|

Sand fill the tube to be bent and it won't crush....gentle heat will make it easier

|

|

#7

|

||||

|

||||

|

Beading Mark .... Not bending

I blame the Black stuff I blame the Black stuff  Here's another of my dodgy sketches !!  Is that what you was thinking Les ? The lower former could make use of an old woodruff key, inverted & tacked into place . Or a profiled piece of hardened steel. The upper former could be made with a small round file or ground out. A tad oversize to the lower former to allow for material thickness ( A couple of mm's should do the trick ) I really must learn to use the Autocad or Solid Edge software I have installed on this PC ....... I havn't got the faintest idea

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk |

|

#8

|

|||

|

|||

|

Quote:

i reckon thats almost marketable perhaps you should put a patent on it............. or make me one to test for when my wonky leg is better lol cheers les g |

|

| Thread Tools | |

| Display Modes | |

|

|