|

|

#1

|

||||

|

||||

|

Hi,

It is very hard to find an exhaust manifold for my 2.0i DOHC which will fit the Roadster. But I found this on ebay: http://www.ebay.co.uk/itm/FORD-DOHC-...item565870f6e3 What do you guys think ? Will it be difficult to weld? Is it an OK price? Thanks.

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://cafrazx550.blogspot.com/ |

|

#2

|

||||

|

||||

|

I would suggest you buy a KitSpares header without a flange, then get a flange cut locally and weld it on with your MIG. My KitSpares header has a 5 mm mild steel flange on it. Ask for a GT one, this fits the Roadster chassis width nicely.

http://www.kitspares.co.uk/shop/item...=9082&catsub=0

__________________

Albert Haynes Roadster FAQ | Haynes Builder Locations Gallery, build thread in Lithuanian / via Google Translate. |

|

#3

|

|||

|

|||

|

Voucht - I bought one of those off the same guy when I was building my DOHC engined car. It was total rubbish, I sent it straight back to him. It simply did not fit together, not even slightly. It was a bit of a process to get my money back too so be careful. I ended up using the standard ,manifold and a custom fabricated down pipe.

|

|

#4

|

|||

|

|||

|

I've done the same as Enoch. Standard manifold then ground out the twin pipes from the flange and put in a short 2-1 section. Not finished yet but will join to 90 bend.

Matt |

|

#5

|

||||

|

||||

|

Hello

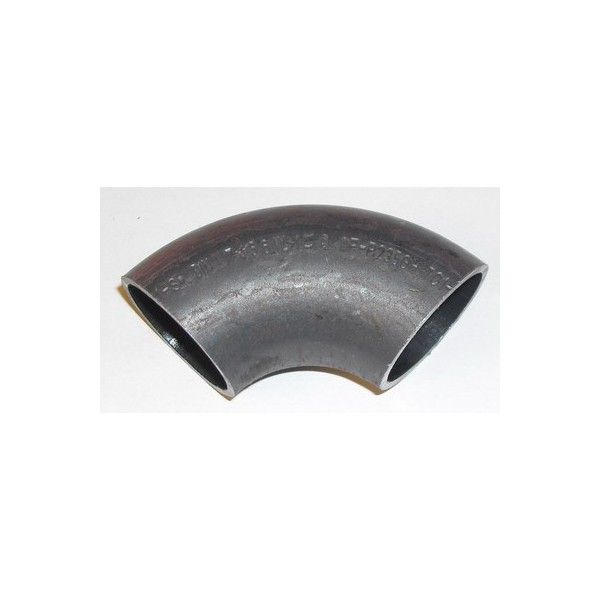

Sorry for the late reply, I've been away from the forum for a little while. Thank you very much for the replies. Albertas, yes, this manifold looks great, but I just can't afford it now (with shipment, it will be up to 250 Euros). I will definitely install a nice and good looking manifold later, but my goal for now is to get the car on the road, and if I am not careful with money, I will have to add my name to the list of those who gave up their build, and I don't want that. So I need a cheap set-up for my exhaust manifold, even though it does not look that good. But I really hope I can afford and install a proper manifold in the future (I bookmarked you link, thanks!) Enoch and Matthew, thank you for the advice. OK Enoch, I will definitely not buy this «kit-manifold*» if you say you've tried it and it is crap. That is why this forum is great, sharing our experiences avoids each other to make the same mistakes:-) Thank you for that! I saw the picture of your manifold and downpipe a while ago on your blog, and that would have been my plan from the beginning... if... I was building a RHD car! Unfortunately, my steering column and pedal box are on the left side, which is the DOHC exhaust side, and it is very busy down there! So I'm trying to sneak the downpipe between the steering column and the master cylinder, but all the solutions I thought about so far just failed. I shorten the Y part of the original down pipe to be able to fit a 90° bend towards the outside. But considering the curve radius of aftermarker exhaust elbows, even if I cut this bit just above the lambda sensor, the bend will be too close to the master cylinder anyway (especially the front inlet-I'll have remote brake fluid reservoir).    But I found this kind of steel elbows. I don't have it yet, need to order on internet.  Diameter is 60mm with 3mm walls, it will fit perfectly on the Y downpipe I modified. I'll cut ite just above where the lambda sensor is now (the lambda sensor will be re-located on the cat anyway) to get the 60mm diam. This elbow has a very shot curve radius (about 60mm I think), so it should be perfect to go under the steering column, and quite far away from the brake M/C outlets. I might add a stamped aluminium heat shield between the elbow and the M/C anyway. Then, on this elbow, I'll weld a 55mm straight tube which will cross the side panel. This could be the cheap (£6 for the elbow) and easy solution , we'll see!

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://cafrazx550.blogspot.com/ Last edited by voucht : 27th July 2013 at 05:56 PM. |

|

#6

|

||||

|

||||

|

Just a follow up on this problem : exhaust manifold for a Sierra 2.0i DOHC on a LHD chassis. I add this post mostly as a reference for future builders (but who else than a French guy living in Sweden will build a LHD car with a 2.0i DOHC from a Sierra

) )I made a set-up with an elbow as I said on the previous post. I reused the 2-in-1 tube I did previously, and inserted a 90° elbow.  2013-07-31_10-56-06 par Voucht71, sur Flickr  2013-07-31_15-43-36 par Voucht71, sur Flickr This was not satisfying at all : the exhaust pipe is in deed too close to the master cylinder and brake lines. Except using a heat shield without being sure it will be enough to protect the brake fluid to overheat, I can't see any way to use the original Sierra DOHC exhaust manifold on a LHD Roadster.  2013-07-31_16-15-03 par Voucht71, sur Flickr

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://cafrazx550.blogspot.com/ |

|

#7

|

||||

|

||||

|

But the Ford Scorpio's manifold (only 2.0 DOHC after 1995-98) has the same head flange as the Sierra DOHC manifold, but the downpipe flange is going straightly down and not backwards as the Sierra one does.

Also, it is a 4-in-1, and there is no need to insert a 2-in-1 Y-piece as it is with the Sierra manifold. The Scorpio manifold is consequently much more compact. I bought this manifold for £50 at a local car breaker, not cheap, but still cheaper than a custom made manifold.  2013-08-28_16-21-42 par Voucht71, sur Flickr First, I had a doubt because once the manifold fitted, the downpipe flange was very close to the steering column, and there was no way I can weld a 90° elbow directly on it.  2013-08-28_16-53-03 par Voucht71, sur Flickr So I cut the flange, timed the manifold as much as I could, and also trimmed the elbow to allow an acceptable clearance.  2013-09-14_14-23-54 par Voucht71, sur Flickr This gives me about 15-20mm clearance above the steering column.  2013-09-14_14-27-17 par Voucht71, sur Flickr I'm quite happy with the result, and even though a 4-in-1 tubular manifold like the KitSpares one would have looked better, the saving (more than £200) is worth it. I'm very glad I could find a "cheap" solution to this problem.

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://cafrazx550.blogspot.com/ |

|

#8

|

||||

|

||||

|

Good on ya Sylvain! Making progress on the cheap is the name of the game, you'll always be able to improve it if you feel like it when the car is done.

Was the cast iron hard to weld? Did you do any special prep like heating it cherry red?

__________________

Albert Haynes Roadster FAQ | Haynes Builder Locations Gallery, build thread in Lithuanian / via Google Translate. |

|

#9

|

|||

|

|||

|

That's a really tidy job. If I hadn't done as much work on mine as I have already I'd be tempted to do the same.

Matt |

|

#10

|

||||

|

||||

|

Thank you very much for the comments guys.

Albertas, no, I didn't find the cast iron that difficult to weld. Of course it is melting quickly, but there was no particular difficulties with the MIG, as the steel thickness of the elbow is much smaller than the cast manifold. And I haven't particularly prepared it except for the cleaning-grinding-degreasing part. Should I have ? For what reason ? Anyways, after de-rusting the manifold by electrolysis (I just love this process, it is magic!)  2013-09-18_11-07-22 par Voucht71, sur Flickr ... plug-welding the Scorpio sensor holes...  2013-09-18_13-25-29 par Voucht71, sur Flickr ... some smooth black high temperature paint...  2013-09-19_17-38-37 par Voucht71, sur Flickr ... it gives a nice finish.  2013-09-19_17-42-18 par Voucht71, sur Flickr Would be great if the whole engine was looking the same... may be one day ! Thanks.

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://cafrazx550.blogspot.com/ |

|

| Thread Tools | |

| Display Modes | |

|

|