|

Quote:

|

Quote:

|

Yeah, could well do kev. I managed to re drill and countersink the holes in the wheel to fit the boss but I could have just been very lucky.....

|

Well done Kevo ! That middle picture reminds me a little bit of a cyclone. I take it a classic mini wiper motor is on the agenda then ?:D it may be easier & safer to flare the bodywork to match the screen than cut it. Lol.

|

When are you fitting a heater ? :p

|

If it's toughend glass you will be very very very very lucky to cut it.

If it's not toughend and not laminated then you will want to deplace it as the fisrt stone hit could send a shard heading in your direction. Will be a custom order job. TT |

Jase.....could be bud then again a sierra bodge could be on the cards

Paul.....as above matey as above:p tt....me is thinking wet cut diamond tile cutter as I think it is all square underneath.....anyways I have a few tanks to sort oot first and the missus's "list" to get through yet:( |

If it's toughened then it will almost certainly 99.99% explode into a million bits. Even with a diamond cutter.

Laminated should be ok if you do a cut accutarly on both sides andthen carefuly break and cut the membrane layer. Plate. Simple enough to cut but I would not want it in any car I was driving. TT |

Chatting to my mate last night and he said that autowindscreens will cut any shape windscreen providing you can give them a template.....unsure of price but could work out cheaper than hassle and hospital appointments :D

Russ |

If you want toughened glass and its a flat panel then make a template and take it to a glazier.I had one made for my boat for next to nothing. Toughened glass will always have a kite mark or manufacturers mark and is heat treated(tempered) after cutting and edge grinding. Dont even consider trying to cut it.

|

Company called Spartan do plant glazing in the NE Kev (No everybody not flowers)!

Worth a look. |

Gonna start getting ready for this summer now and first thing I am going to look at is a home brew version of a 3" straight through cherry bomb using stainless wool instead of the traditional glasspack.

there is only 1/4" between the inner core and outer body this is due to the heat shield I have being only just under 4" dia so everything has to be quite compact, you will see what I mean over the next few days the raw materials:D  |

Looks interesting!

Just to warn you, I packed my exhuast with wire wool to get through IVA and it disintegrated into dust after a few hours of driving! |

It better bluddy hadn't John:mad: as it is the proper stainless stuff from an exhaust company.

|

Ah, you're should be alright then. Mine definitely wasn't proper exhaust stuff!

|

So I have started with the outer case and some heat and gentle persuasion with a nammer and it all curls round enough to make a nice tight fit for the 3" perforated inner of the bomb

next was to tig on a 90 degree bend that would eventually be sliced to allow it to go inside the cast exhaust outlet of which I will be refurbing and possibly getting a proper rechrome    |

|

|

|

Nice one as usual ,did you get that pm I sent you?

|

Ooops sorry Paul ...I meant to acknowledge it but forgot... anytime matey its not going anywhere

|

Brilliant,no worrys I will be down to collect as arranged.

Thanks again. |

Right ....have been having a little think and have come up with a much cheaper solution to the re-chroming that I was going to go for (although it is still a possibility) these pics are a quick mock up using chrome vinyl wrap......now I know it may be questionable next to a hot muffler but for the sake of a fiver it is worth a bash as the muffler does not touch the heat shield until the very rear and I am leaving the front open to allow cooling air to flow between heat shield and muffler .....will be running the engine up tomoz to find out if it is a non starter if it works then I will be ordering some more to do a better job of it.

|

Can't you get a cream for that

Arfon |

Beat me to it,damn :p

|

first up best dressed

|

Now if I start putting Canesten on it the chrome effect will suffer:p :p

|

Nothing better to do !:rolleyes:

|

|

Does anyone manufacture an extra long nosecone

Arfon |

Hi Kev,

It might be time to think about a Laminova for cooling the oil, they are very efficient and space saving. And/or a air-to-water charge cooler for your turbo. These parts are a bit costy, but very welcome when it is as crowded as in your nose cone ;) Laminova coolers are imported to the UK by Think Automotive. We import them in France from them. Laminova website : http://www.laminova.se/ PWR makes very good water-to-air charge coolers, and other kinds http://www.pwr.com.au/products/intercoolers The factory is in Australia, but they have a company in the UK. I am aware it is a question of cost, but if you can afford one of them, it might be a route to explore. |

You should know me by now Syl.....charge cooler from a mr2 turbo just been fitted, this has its own electric pump which I will be controlling via an adjustable temperature module which will also display charge temps. as for oil cooler I just need to get some pipes made up....I have manage to squeeze it all in with only 5mm spare in some places.

It feels quite odd carrying on with the build even though IVA has passed and gone. Mr2 2 litre turbo water to air charge cooler ....played with a bit carbon wrap  Have managed to keep the inlet pipe run as short as possible which will help a lot with turbo lag .......bailey dump valve to keep turbo rpm up during gear changes  12v water pump in the charge cooler loop  getting very busy in the front  |

Sorry about that Kev. I hadn't noticed you already have a water-to-air charge cooler, and I thought this water radiator for your charge cooler was the new oil cooler as it looks like these very thin plate-and-fins oil cooler. I was completely wrong :o

BTW, I like your installation of the charge cooler :) |

No room for the driver shortly (No Kev not you) :p

|

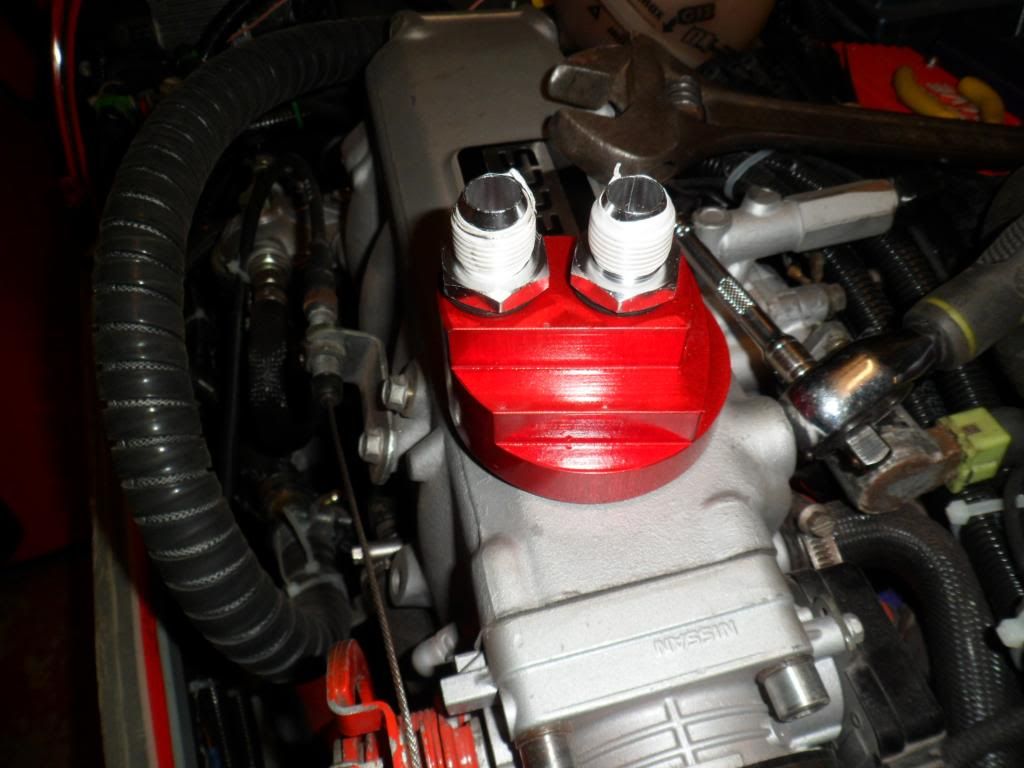

A couple of days ago I hit on a real bargain, off of you know where:D

I had worked out it was going to cost me about £50 for pipes to rig up the oil cooler (uh nee way) so I start searching on my fave auction site and find a BIN oil cooler package, but thinking it was too good to be true (£70 delivered) I asked them a question and they confirmed it was everything in the photo, why I here you ask....well....here is why.... not only were the pipes stainless but it also included a oil filter re-location as part of the kit, needless to say for the sake of £20 it was a steal and last one too and 2 days delivery  |

Started to install my oil cooler stuff, from what was a cavernous engine bay is now looking like a modern car (no space to put any aftermarket goodies) anyway before I got started I decided to anodize the two major alloy bits, then I got to installing the oil filter re-locator and fix the new slightly smaller (2 rows)

oil cooler below my rad then started to route the pipes, hope to finish install tomorrow     |

Small disaster.....when fitting up my oil cooler pies I managed to x thread one of them which showed itself as a leak, I would not care but it did not at all feel tight when I was screwing it on, anyways off it came and sure enough x threaded only thing I could try was a re-tap as some of the threads at the bottom were still good but I have no an10/jic10 tap so remembering that I had an ancient scrap ride on in the garden that had hydraulic fittings I checked to see if there was any an10 nuts and there was one... so took this off put it in a vice and using a junior hacksaw cut around 7 slots across the threads, these would provide a cutting action if I can get it square on the damaged fitting.

using it very carefully I managed to get it square on the old threads then proceeded to put it on ...turn a bit take it off, clean it and repeating this action every third of a turn I managed to recover some of the threads that were not damaged. I think there was a modocum of good luck. Right so oil cooler back in and taped up (lots on the rethreaded one) I was able to apply the same torque on both nuts with no sensation of "stripping" That was last night and I have not tested it yet, I was really peeved at that mind BUT joy of joys, my age related number and tax disc turned up this morning K7**BON yep ...tres tres bon indeed. well it would be if it wasn't bluddy raining....will let you lot know how it goes soon :D :D :D :D |

Hi guys....it has taken me ages to get the bluddy engine sorted and finally after changing and checking injectors, cop's, igniters, ecu's I finally discovered what was wrong ....it was disgustingly simple which annoyed the f**k out of me, I was running to low a fuel pressure 28psi when I needed at least 36psi so I whacked it up to 36 and went out a few hours ago and scared myself half to death:eek: the acceleration is effin mind blowing, it has taken me long enough to vindicate my choice of power plant and I have yet to take it up to stage 2 but not yet as I don't think I could cope with another 50 horses on top of what I have without seriously soiling my pants.

So now I can say anyone up this neck of the woods wants to see and feel what a fast roadster is like just drop me a pm, only proviso is it has to be dry with no chance of rain:rolleyes: :rolleyes: will get a vid sorted out soon when I find my camera mount. |

Ooo ooo me me please

|

| All times are GMT +1. The time now is 02:54 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.