|

Quote:

Again thanks for all the positive comments guys.....am hoping to take out the wiring loom out of the sierra soon and sort out the stuff I do not want also would like to get the floor on so keep watching there will be an update/piccies soon |

I haven't been on the forum for almost a week (travelling in France), and I really want to congratulate you for the chassis, it looks really good... I wish mine could look as good :eek:

Good job mate :cool: |

aaaaaarrrrrrrrrgggghhhh

AAAAAAAARRRRRRRRRRGGGGHHHH:mad:  PHEW....TFFT  |

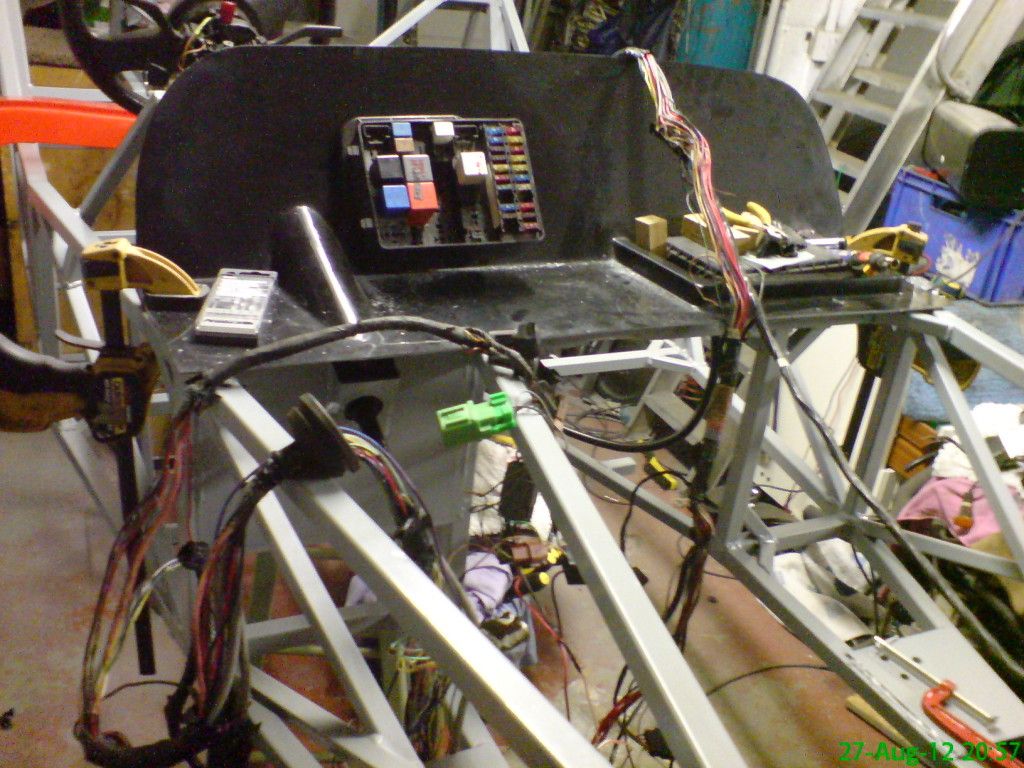

Would it be spaghetti time kev

|

Yuk. I hate electrickery. All those supposed wires are really just lots of tubes filled with smoke ready to leak at the first opportunity:eek: :eek: good luck with that lot Kev

Bob:p |

Quote:

Bob |

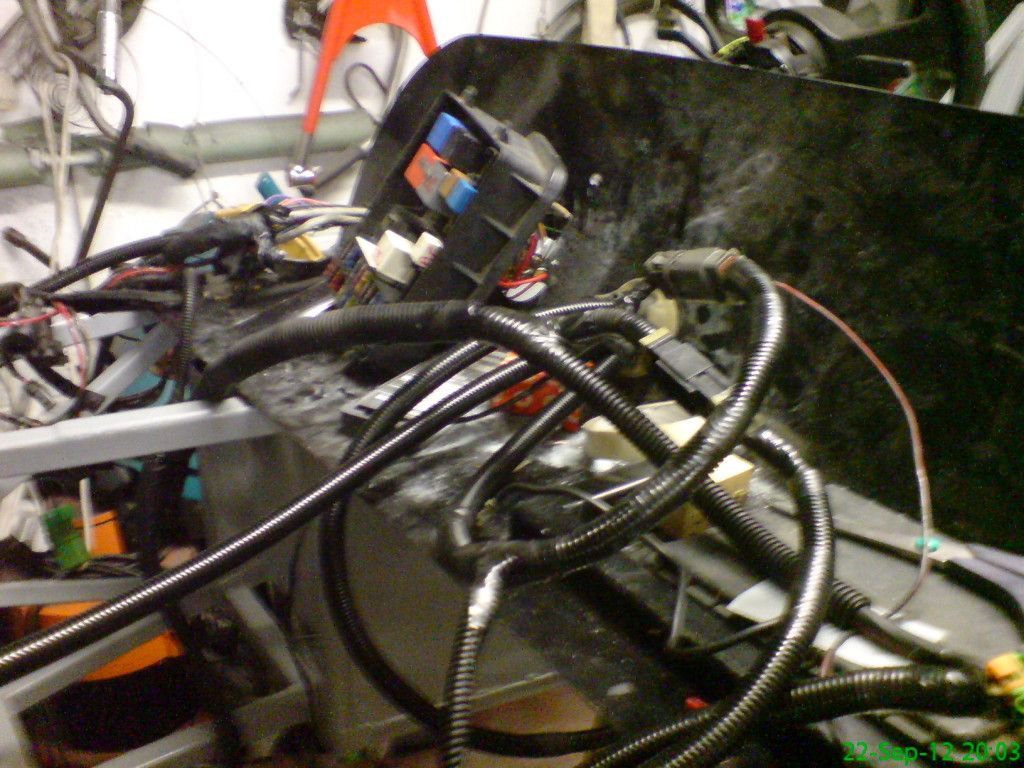

not yet Bob....want to sort the wiring out....sierra loom now half the weight that it was, but I have just been to look at the 200sx's engine loom/ecu....sh*t it looks like a sierra loom untouched ...gonna spend tomoz taking that engine out and into the shed with it. then I will be able to get to all the loom need g/box end of prop shaft anyway .....not got a lot done lately due to nice gardening weather (my other passion)

I will get around to completing the tank pretty soon I hope as the other thing I need is the fuel sender from the 200sx . |

crikey ...long time since I posted on my build, currently at the stage of routing wiring loom also trying to splice in the ca18det engine/ecu loom which is a bit of a nightmare.... so many sensors etc....anyway will soon be time for me to lift off the loom to start floors and fitting mechanicals. It will come together very quickly then, as most of the other stuff I have already made, so expect a hive of activity over the next few weeks....as ever a few photo's

|

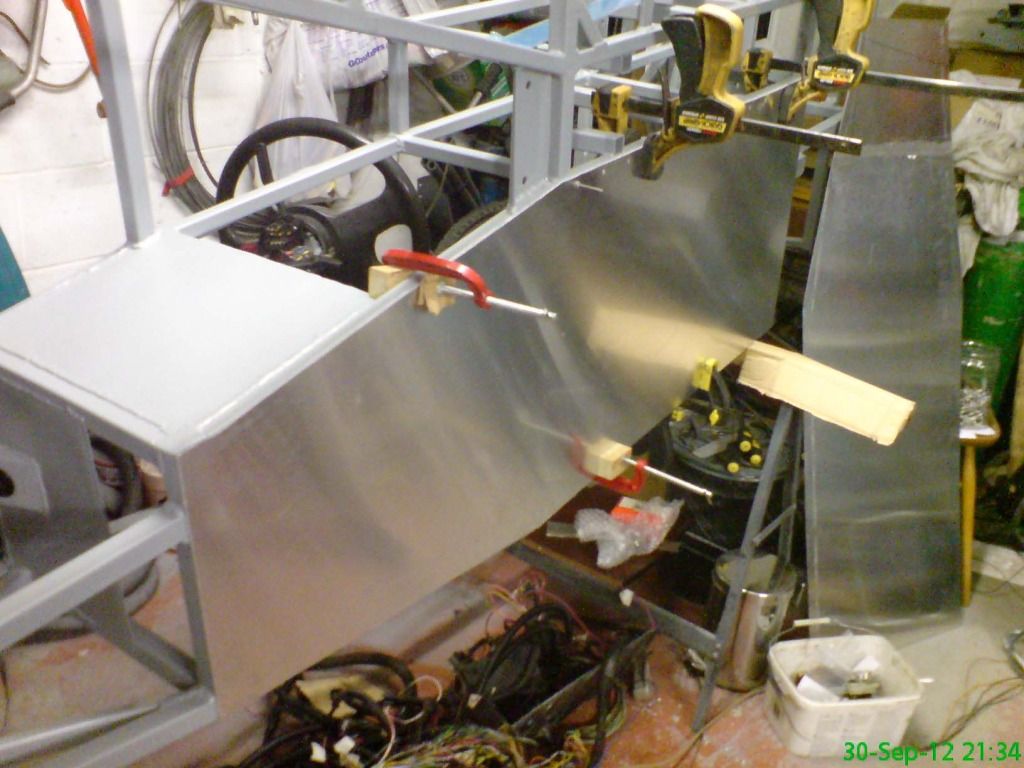

been busy prepping and cutting the floors and now at the stage of drilling and countersinking, then I am hoping tomorrow will see me with sikaflex and rivet gun

decided on 3mm ally sheet fixed at 2.5" spacing with 4mm countersunk sealed rivets temp fixed and waiting to be marked for rivets  drilling holes  now countersinking the holes to allow a totally flush fit with coiuntersunk rivets  |

managed to get the offside floor sealed and riveted on.....I'm pleased I chose csk rivets because a quick check of my side panels inner dimension top to bottom leaves no room to spare.....had I used plain rivets it would have been a "force on" issue or remove a lip....phew.

drilled up the nearside floor, so will be mounting that proper tomoz here come the piccies    |

| All times are GMT +1. The time now is 01:49 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.