|

PM sent to you Kev :)

|

Wupeeeeee....got me stuff from 3ge, caused bit of a mental barrier waiting...I know I could have got on on with other jobs but could not get it into my head that I NEEDED the stuff I bought.

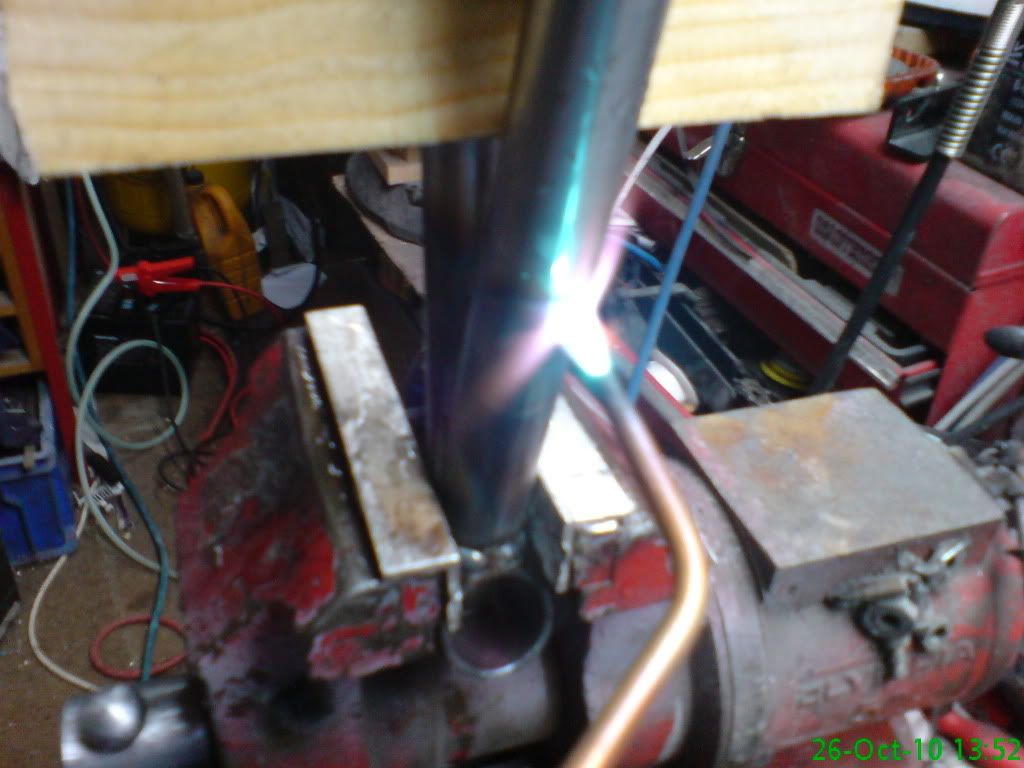

Made one of my first bones ....worst one as well, being bottom rear....was very tempted just to do it ladder style ie get rid of that diagonal, but no I persevered. Tube mitre is very good but it still requires you to 'fettle' quite a lot, as using the tube thickness in the app would render it way to thin at the edges to mig so I guess everyone else has found a "halfy halfe" remedy to satisfy the critical dimensions and yes mine distorted too when fully welded but a little "heat line treatment" (a neat trick I learned at the shipyards) brought the tubes back in spec to the mm .....in effect it cancels out the initial weld contraction so a few pics using the cnc'd wooden jig  more than a couple of mm out should be 206  heat line treatment (has to be cooled immediatly with water but not dipped)  three of these treatments and a couple of strategically placed wedges and were right on the money no brute force used  Next stage should be interesting as I intend to nickel plate the bushes and the 1st inch or so of tube for the ultimate in corrosion resistance. |

Looks more like 205.62mm to me not 206!! :D ;)

Good work I was gonna try heat rather than brute force when i corrected my distortion but im impatient so went with the latter! |

Gonna buy you a dicky comb:D :D

|

Well....been away from the build for a few months trying to master the art of electroplating (see separate thread on Nickel plating) but because of the plating op turned out so well it has given me a boost so I have been back into the garage and re established the build.....so far in the last couple of days I have made up the rear tub 1" bracing since I am going to use the glass tub and today I got stuck into cutting the trans tunnel sections so will be constructing that tomorrow.....

just a couple of piccies   |

Coming on nicely Kev

Looks like you are making some good proress there :cool:

Tis strange how easy it is to get stuck in the mindeset of " I must finish this part before I move on " :) Been thinking about having another crack at electro plating at some point .... Got as far as basic copper plating, then got hacked off trying to find the chemicals to take things further ( Had wanted to do some chrome plating ) Well done on your progress to date :) |

Cheers Ronnie....did consider chrome, but too many nasty chemicals involved to get it spot on.... nickel baths you can even put your hand in (dropped a tube in once had to fish it out) as long as you wash it straight away. Gateros plating and caswell do the best kits but as I discovered the most important ability is to be able to control the dc volts and current.

|

Bin a while now since my last update....(too cold for the shed) Anyways since becoming pretty good at nickel plating....I sensed it was time to put it to full use on me bones dem bones dem bones dem dry.... sorry couldn't help that.

I had made a start on them before but not with the object of completing them, so a week ago I set about finishing them off......not finished yet but here is a sneak preview....I have to confess to getting totally carried away as you can see.....final picture is of a totally completed front upper wishbone nickel plated ends only sprayed traffic red (bodywork colour) clear lacquered and polybushed up, mega satisfied with the result and now working my way through the other 7 so this is what the bones looked like at the start  now a bit of welding..grinding..welding..grinding etc etc  extremities now nickel plated (2hrs per each session)  painted, lacquered and bushed up and soon to be wrapped in cotton wool  |

WOW Kev......that looks stunning :cool: :cool:

Cotton wool needed indeed, the bones will look great on your Roadster , nice work mate :cool: cheers andy |

They look fantastic, never ceases to amaze me how different the same thing can be, if you know what I mean.

Cheers Ginge |

| All times are GMT +1. The time now is 01:32 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.