|

I'm also thinking about how to do the floor. Can't decide whether to go aluminium (apparently Westfield etc do) which runs a risk of corrosion because of contact with the steel, or steel - which doesn't - but does run a risk of good old fashioned tinworm.

Seems people have done both - and no-one can make a great case that one is better than the other!!! It looks like putting extra support for seat runners is a good idea - although if you have box section I think you then need crush tubes - so I will just be using some strips of 3mm steel. |

I've gone for an Aluminium floor with sealed rivets and sixaflex. I'ts going to take decades before it suffers galvanic corrosion, after all you need to add salt water for this to take effect! So don't drive your car during rain on salted roads.

As for the Tatey lower steering support, give us a clue as to what that means. |

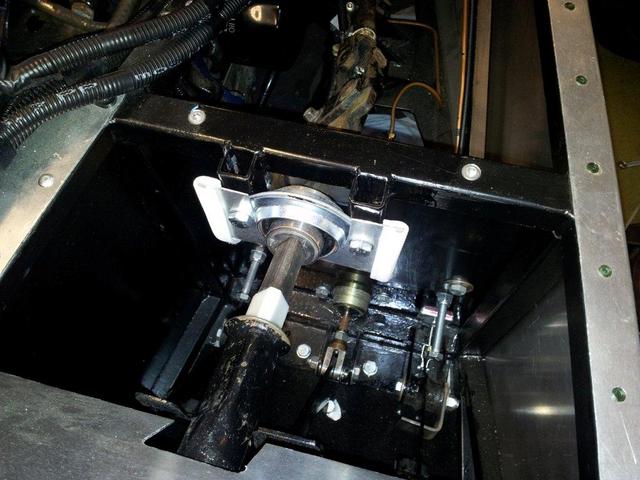

Right, had a look and assume you mean the bearing. I've done that on my car as the sierra bush is a load of crap and wobbles like hell. The proper bearing is a much nicer solution to supporting the shaft. Mine is bolted onto some box section. Then to avoid any IVA whining about the edges I made an little aluminium cover and even trimmed the edge. In the end they never checked it....

|

Regarding ERW wishbones, it's a taboo subject. Not many people on here are structural engineers. The general mindset is that wishbones are a safety critical component, so compromising on their strengh is not something we laymen want to give advice about.

As a *cough* software engineer *cough* I would say that most probably you will be fine with ERW wishbones, and you should look at a thickness of 2 or 2.5 mm. The quality of your welding will probably be a more important factor than the ERW/seamless choice. |

I used 3mm aluminium floor sealed rivets and sika with regards the seamless tube for wishbones I would go for seamed tube as the little seam inside grips the polybush and stops it from spinning

|

2 Attachment(s)

Quote:

Attachment 1501 If you chose this option, you will also need to machine an insert (bush?) to adapt the triangular shape of the steering column to the 30mm bore of the bearing: Attachment 1500 May be not the best solution, but at least it is another option:) Good luck! |

Fantastic! Cheers for the info guys.

After that I will definately be looking into other bearings, seems like its almost the norm to improve this (I have noticed the poor quality of the old bush). And yes Deezee, that's the bit I meant! My main reason for wanting to use the roof for the floor is to keep costs low. and large sheets of Ali are a little on the pricey side :o I'll keep my options open on that one for now. I am a Mechanical Engineer and the only reason I can see for ERW beeing bad is for its reduced fatique resistance due to the grain hardening caused through the application of heat (Harder = Brittle). Around 2.5mm wall thickness sounds about right, need to double check what I had in my notes (when I find them...) Thanks for all the advice so far guys, I'll think some more on it when I'm more awake! |

Progress! Of a sort...

Had some wages so decided to spend out on the tubing for the wishbones. Got seamless in the end (after all my questions on using ERW) due to an inability to find ERW in the right size. So, I'm now starting to make the jigs. Gradually. When I find time... One question, Is there an easily available tubing for the ends of the bones? (where the bushes are inserted) I couldn't see any on the bay and I've read various references to reaming tube out for these so... Any about or easier to buy them ready cut/reamed? |

|

I've been watching these,

Just wanting to keep prices down where possible. Cash injection means that I may very well be ordering a few bits from Talon in one go! |

| All times are GMT +1. The time now is 06:44 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.