|

Looking great like normal.

When it comes to iva a few people have been caught out on radius with the long acre mirrors. I was also worried about the handbrake height but it seems to make a perfect arm rest. |

Cheers mate, yeah I'm going to have to use edge trim I think,

As for the handbrake, it's not to bad I don't think, where else you going to put it without making the cable a nightmare |

One of the other companies has it in the passenger side against the tunnel but the cable routing would be hard as you say. It's quite tight as it is now.

|

|

|

|

|

|

|

|

Made a few modifications to my bead roller, welded a handle on to apply the roller pressure and swapped the bottom wheel for a plastic one as the metal one was a bit heavy on the aluminium

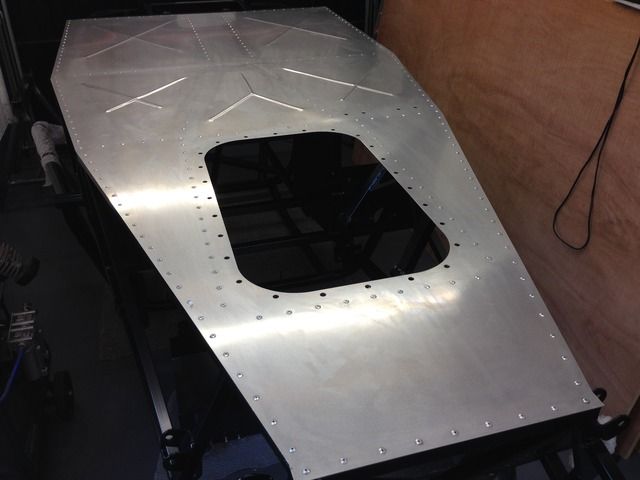

Engine hatch marked out  Finished panel, I was a bit worried about ruining it, but it's turned out perfect, tomorrow night I'm doing the big floor panel :D  |

|

Looking good as usual loving the rollers any chance you put us a set of drawings together for the roller

|

Really nice build there. I have been following all of your thread. I like the enclosed bottom. The only question I have is where will all the hot air go from the radiator etc? Are you going to vent the sides of the body?

|

Quote:

|

Quote:

Could it go down the tunnel and out of the boot floor, above a diffuser? Or yeah I could vent the rear of the side panels and the bonnet |

|

|

Looks awesome mate, the pedal box is really nice. When you taking orders?? :D

|

Well tidy mate, should command big dollar when and if you sell it. (after you have had some fun of course:D )

|

Quote:

About the cooling, I second David on that: plan for vents to let the air flow go out. Also, I don't know if your bike engine is oil-cooled, but whatever it is, I think you will need an oil cooler. On bikes with no oil cooler, I've learnt that the airflow on the sump is enough to cool down the oil. Here your sump will not receive any airflow and there is a risk of oil overheating. Hope this will help :) |

That looks stunning!

I know this is always a cheeky question to ask but, would you be happy to share the quoted cost to coat all of that? |

Quote:

Quote:

Quote:

Yeah I think your right with the cooling, I'm going to have oil temp on my dash so will see how it go's, it's only got a water/oil cooler, I could always swap the under cover panel for a louvered one, will have to make a louver tool then ;) Quote:

|

Got the car spun over tonight and got on with marking the rivet holes out, I've gone for 4mm rivets at 45mm spacing, I'm bonding it on to!

I marked the rail centres on first then used a set of dividers to mark the spacing, wasn't as bad as I thought it was going to be and 45mm worked out nicely everywhere which was good for my OCD!   I started drilling a few holes at the back and worked up to the next cross rail, I had brought some cleco pins and glad I did there perfect for the job Because I had bead rolled the panel it wasn't as flat as a plain sheet, but it pulled flat as I worked my way along  20 cleco pins fitted  |

|

Faip play cracking build

Where did you get the colecos was it online can only seem to see them on ebay usa. |

Quote:

|

LAS Aerospace for cleco pins,good price and delivery don't forget the pliers too.

|

There made just down the road from me

LAS Aerospace Ltd Okehampton Devon EX20 1UA 01837 658081 |

Quote:

I got them off ebay, but looks like i paid about double compared to the las aero thats been mentioned :mad: |

Quote:

|

Well got the rest of the holes drilled last night and debured

I used Wurth Bond and Seal to bond it on, just put a small bead down the middle of all the rails covering all the holes, it was just enough as I was still covered in it! My mate let me use his air rivet gun! It's a good job as there's no way I would of done it by hand    |

|

|

Hi again, can I ask what size rivets you used to attach you floor please?

|

Hi, what size rivets did you use to attach your floor please?

|

Stupid forum! Sorry I wasn't being impatient. Each time I tried to post a message it told me to get lost and didn't show the message!

|

No worries mate, I used 4mm rivets, I felt 4.8mm were a bit large, I spaced them at 45mm apart, looks ok I think, I've used a good quality adhesive to

|

|

| All times are GMT +1. The time now is 01:49 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.