|

|

|

|

Engines back in to with stronger clutch springs

Gear linkage next, just working out the size of the bell crank to be made  Down arm added to gear lever, this will be shortened once I've decided the holes in the right place  Lastly put some skateboard grip tape on my pedals, also a clue as to what sort of colour scheme I'm going with  |

Jealousy is flowing freely through my veins!

How did you drill the bottom row of rivet holes in the rear panel without the floor getting in the way? |

Quote:

Haha thanks! Urm I dunno really, I just angled the drill away a little, it was close but it's quite a slim chuck on my drill |

|

Quote:

|

|

|

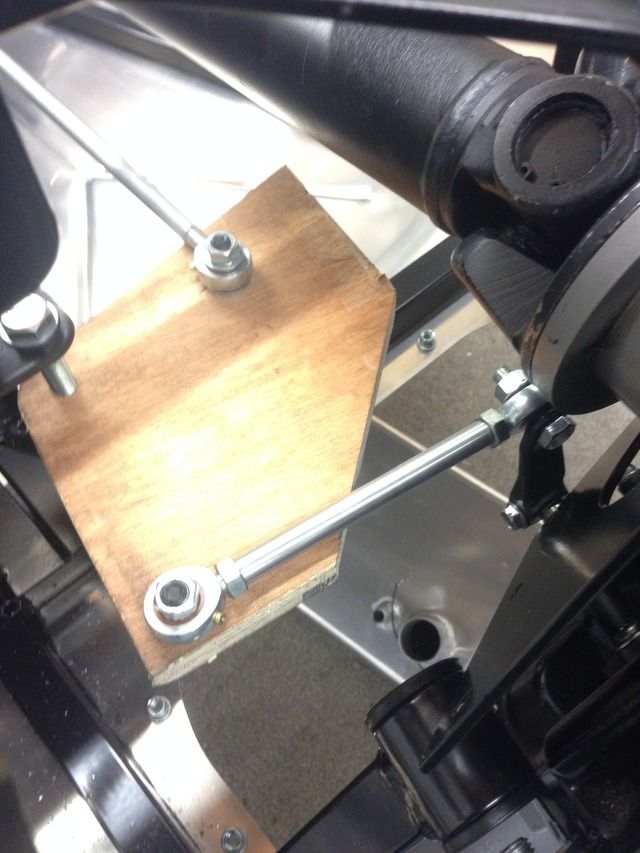

Update for the weekend, my gear link bars were 10mm Ali tube with a 6mm bore, drilled and taped m8 in the ends but I didn't feel they were strong enough so made some with 12x1mm stainless tube with threaded slugs in the end, these just need tigging in

Then onto my fuel pipe, 8mm cupro, drilled a bit of plastic to straighten the tube with, worked great  The routing was a bit rubbish due to the electric reverse but it turned out a lot better than I thought in the end Rear  |

|

Its still the cleanest build I have seen where is the grime very jealous here

|

Quote:

|

|

|

|

Congratulations, it's really looking like a bit of a weapon! I look forward to the day I can fire mine up.

|

Quote:

|

Cheers, yes it's coming along. I'll keep my fingers crossed for you and your iva plans, surely the most efficient yet high quality Haynes build so far!

Are you going to fabricate your own air box? |

Quote:

|

|

I'm happy how they have all turned out but I did find it a bit of a faf about, the fittings I brought from various places are all different, also you read about sae and din flares etc, in the end I did test flares in all my fitting types to check they seated properly and the back edge wasn't damaged by the fitting, also when I tighten them up I'm going to undo them and check the flares have seated correctly, I'm going to get my brake flex's made up tomorrow to all being well! |

Some very tidy work going on :)

The first engine start on any car is always a pinical moment. TT |

Looking spot on like normal.

One thing I will mention is how your brake t's attach. Very early on with IVAs AshG on here (I think) failed from not having the t bolted through the rail. It may be worth while replacing the riveted brackets with bolts instead. Or at least have a search /ask on LB if anyone has recently been picked up on it. Also the 8mm outlet on the corsa header tank is fragile. I managed to snap mine off when doing up the jubilee clip. At least your using the spring clips. |

Quote:

Ok I will be carful with the tank then Cheers for the input |

Just had a search and ash had used a nutsert and failed because of no locking device, I just think bolting all the way through looks rubbish

|

Quote:

It may have been a teething stage. I've never heard it again but thought it was worth a mention. |

Quote:

|

|

|

Good bit done tonight, I decided my brake pipes looked a bit bodge in copper colour so put some heat shrink over them, was a right pain in the butt, would of been loads easier before I flared the fittings on the end but turned out ok in the end

Also my dad had cut my fuel tank strap out for me today, just needed to bend it up! It came out sweet, I will get it powder coated I think  |

|

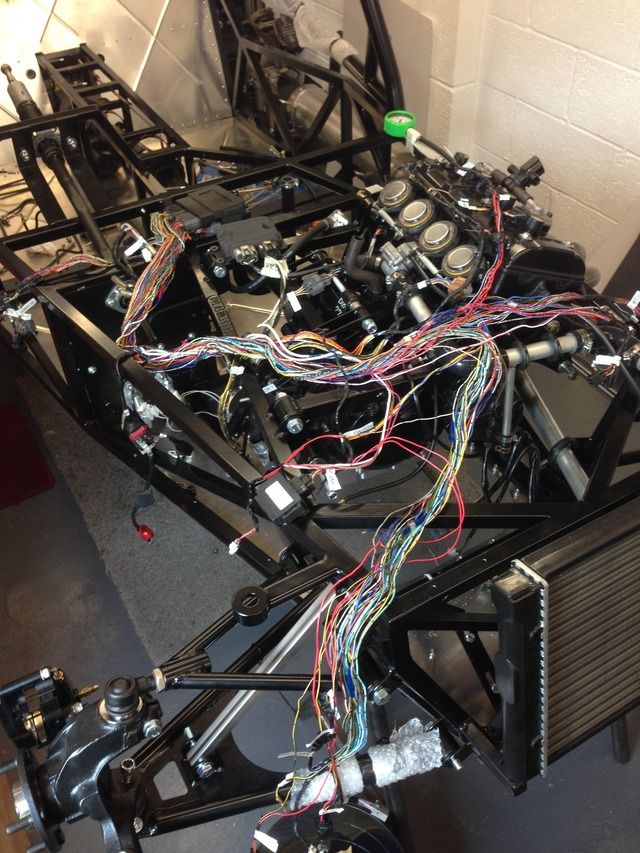

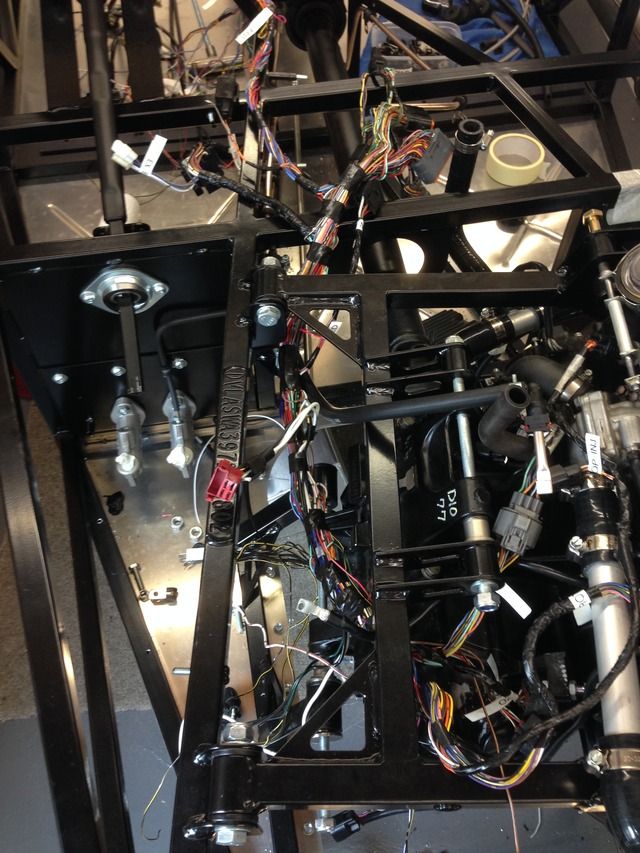

A full day of sticky wiring on Saturday, me and my dad unwrapped the entire loom and relocated everything into position and everything into the cockpit etc, to be fair it wasn't anywhere near as bad as I thought it would be, also we removed things not required like stop watch buttons, sidestand etc, we stripped the lighting back so we just have the feeds coming out of the fuse box, next job is get the lights and dash bits roughly in place and get wiried up

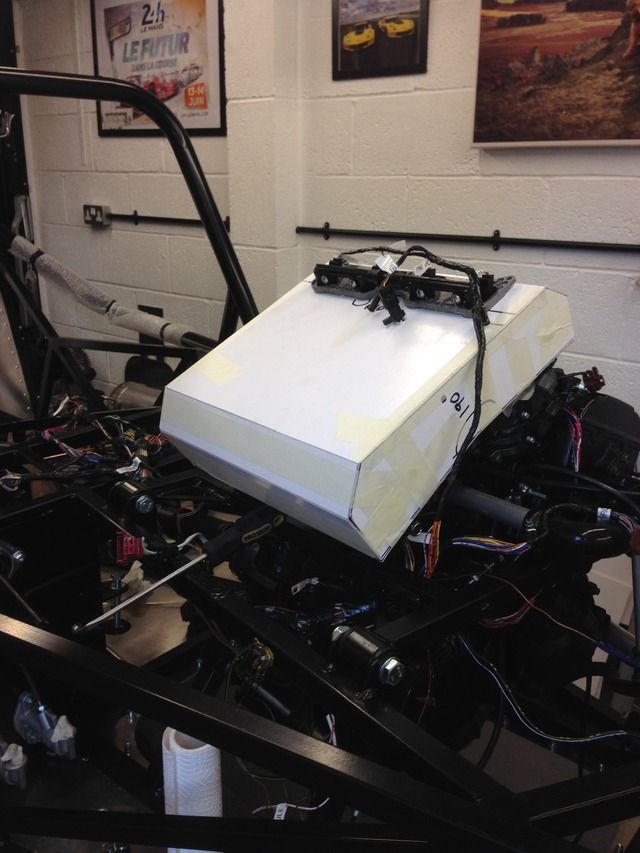

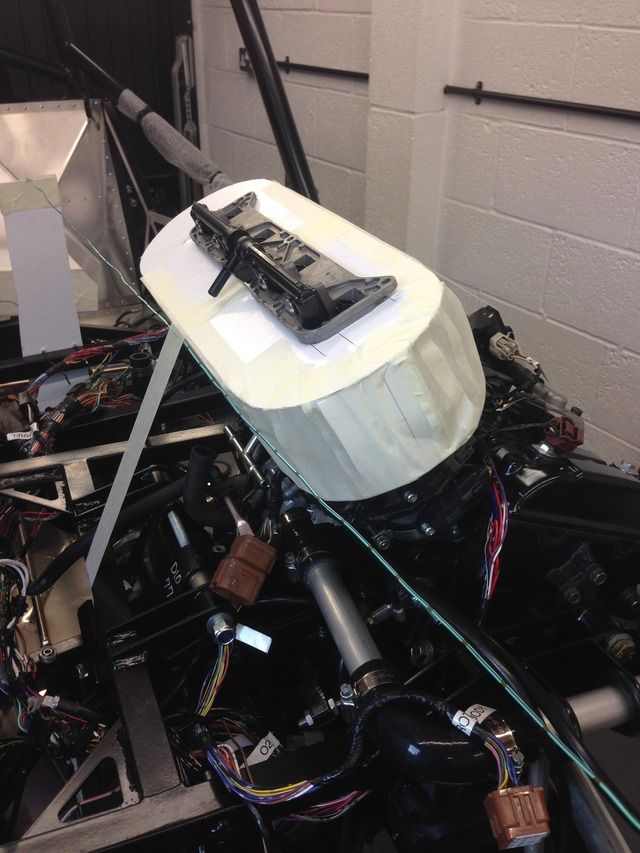

This morning we mocked up a new air box in card, I'm aiming to fab it up in aluminium, the problem is the top injectors, the std box is to high and out to the side, the new idea is a bit lower but not out to the side, I think if I did it as is I would need a bulge/scoop around 100mm high on the bonnet, I'm open to any ideas if anyone has any,   |

|

Here's Big Macs off locostbuilders

[/quote] [/quote] |

|

Right well I've mocked up air box idea number two just to get an idea of size, looks ok, I've mocked up a bit of wire to represent the bonnet line roughly, also I'm a bit worried about induction noise with this method as it's got to be less than 99db at 3/4 throttle!!! Is there anyway of getting this rpm dropped, maybe a new power graph showing peak power at 8000 rpm say??

|

If needed, could the bonnet not form the top cover/half/something of the air box?

|

| All times are GMT +1. The time now is 01:46 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.