|

From what I've heard on other forums you are the one supplying the information about the engines peak power so if you want 8k then that's what it is!

My peak power on my MX5 engine is going to be 3000 rpm - er - no I don't think I'll get away with that - so as long as it half sensible ......... |

Quote:

Quote:

|

|

|

|

|

Well finished my fuel rail bracket off tonight, just got to make a few bosses for it

Then onto the handbrake cables, I thought this would be an easy job but it wasn't, the cables weren't really long enough and not sitting nicely, I was ready to leave it for tonight then I thought about making some exstention tubes  The cables are a snug fit in the tubes and locate on 50mm also it stops them from rubbing on the diff  [url=http://s133.photobucket.com/user/corsaboss/media/September%202015/B44B1114-E9A5-4D6E-9CB4-B761C1846667.jpg.html]  |

|

Don't be tempted to have a "few" notch handbrake as you don't get leverage to give you good brake force,4-5 notches is good .

Nice build . |

Quote:

|

I seem to recall from my youth it was 7:)

|

Long time ago ....:p

|

As long as you get good leverage and it does not run out of travel it should be ok.

Once its up and running try it on the road or MOT rollers,probably not a good idea to rely on adjusting it at the caliper ends and IVA man might not like it either. Basically what you are doing is turning a shaft/bolt against the pads to produce the effort. |

That's looking super, really polished. Can I ask, what's your trade? Do you work for McLaren?

|

Quote:

|

Quote:

|

Ah, so there's some work place skills that come in handy!

I guess it'll be able to move under its own steam soon... |

Quote:

As you moving, yeah not far away, need some shocks and wheels, only thing is I want to get my bodywork first so I can work my wheel offset out so its sits nice |

|

More done today, loads of bits and bobs to do, got my clutch cable sorted, had to make a bit at the pedal end and solder a bit on the other end, it wouldn't solder to start with, to hot I think, but got it done in the end.

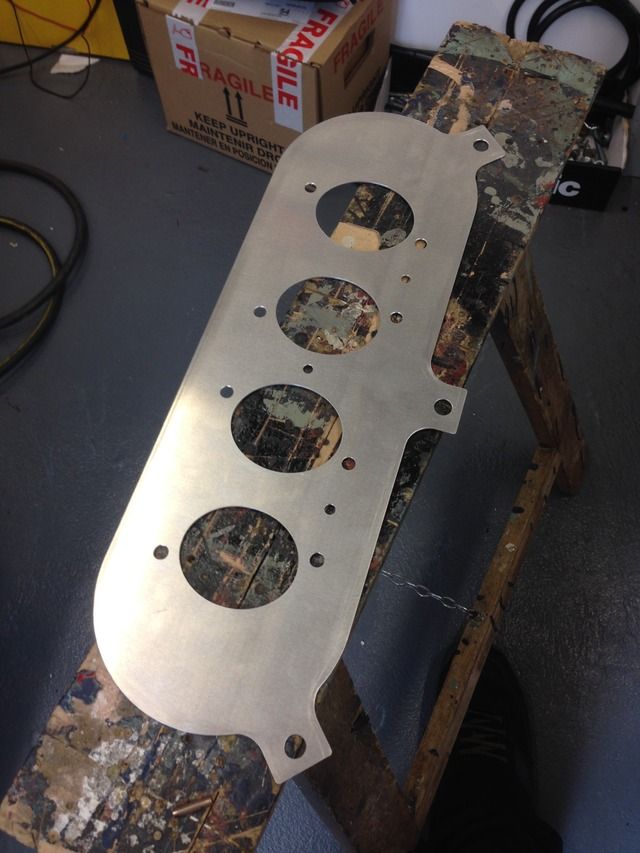

Also got all my aluminium engine cradle spacers back on and tightened up. Then went down my dads and made my air filter backplate ready for the itg filter, I got a drawing from ITG for the outside  Came out mint   Pretty much there now, just need a few holes in it for wiring, air temp and the fuel feed, also need some 3mm spacers under the trumpets to replicate what was there before as it's got orings that seal everything |

|

|

|

|

Is that a home brew cnc machine?

|

Quote:

|

Well got a few jobs done this week, got my handbrake bracket fitted, really pleased with this as its held the cables dead in the right place

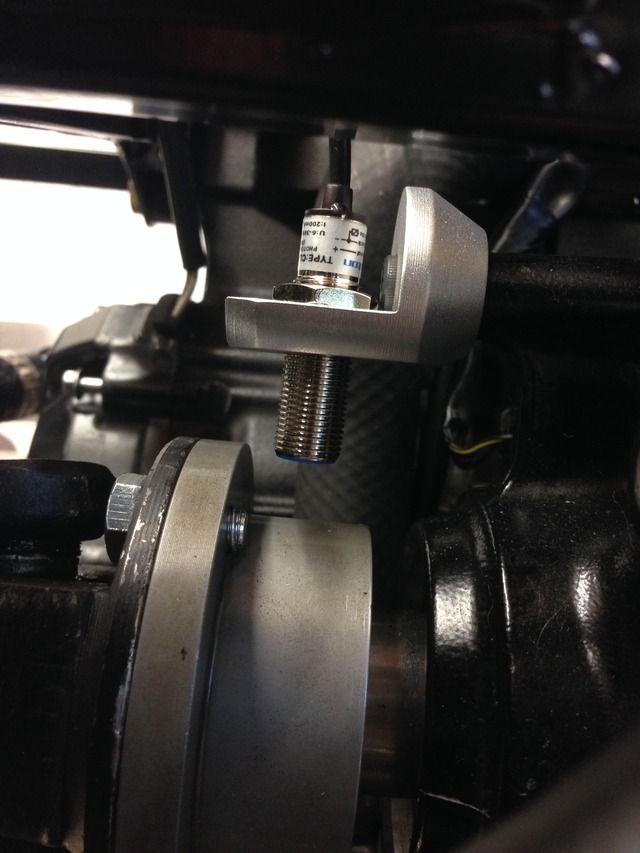

Decided on what switches I'm going to use for my dash, and got some switch guards, only thing there 4mm not 5mm so I think they will fail iva so I'm going to have to push some rubber tube over them I think  Also made a mount for my wheel speed sensor, there was a spare hole on the engine so I used this, it's going to pick up off a long bolt on the prop adapter  It sits closer than it looks, it's just the angle of the pic  |

|

|

|

Looking spot on like normal.

I've got a dash2 as well and had problems with the Hall effect sensor picking up the diff bolts (prop side). I would loose speed after about 20mph. I put it down to the prop spinning too fast. I ended up putting the sensor on the half shafts and haven't had a problem yet. It may just have been a 1 off but it was a pita to change it as I had pretty much got the car finished. A mate also used the studs on the front front uprights but he had the other type of sensor. It also caused Problems at iva as they couldn't do the speed test as the wheels went driven |

Quote:

|

|

Water pump removed, need to block the hole in the block, I'm going to run an electric water pump

And that's it, doesn't look a lot, got a few more plugs to fit and get my switches mounted then I will be linking the rails together, I might get rid of the rails when it's all wiried but I will see, I did it this way as its all laid out and I'm hoping it will be easy to keep track of |

Look great as always? Why the electric pump?

|

Quote:

With an electric water pump, like the EWP's from Davies Craig, if it is connected to an electronic controller, the water circulation in the cooling system does not depend on the engine rev, as it does with a mechanic pump. And the cooling needs of an engine are not always propositional to its rev (overheating when the engine is idling in traffic jams for example, or too much cooling at high speed, when not necessary) The electronic controller is normally connected to both the electric water pump and the electric cooling fan. It detects the water temperature, and adapt the speed of the pump (and the fan when needed) to maintain the optimum temperature in the cooling system, independently from the engine's rev, providing the engine with a very constant temperature. The electronic controller can be set to the optimum working temperature of the engine. The second advantage of an electric water pump is that it does not take mechanic power from the engine (as a mechanic pump does), so a few hp can be gained. Hope this answer your question :) |

cheers for that Sylvain, yeah that's it really, but im not going to be running a controller to start with as i do have a budget to keep to :D

the main reason is heat soak once the engine is turned off, with an electric pump i will be able to keep the pump and fan running once the engine has switched off |

Quote:

|

I need the same continuation of circulation after powering down for my PC...

Is there no diy controller out there that could be made to manage the pump? |

| All times are GMT +1. The time now is 01:46 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.