|

Quote:

|

|

Quote:

When are you going to start putting all the red bits on? David |

Need to do some more tinkering but I've tried the nose cone and managed to get the bonnet to clear the engine, just. Going to just tinker with it for a coupe of weeks, I'm moving offices at work which will require a lot of time over the next couple of months. I have to say it's a huge relief to actually use it and have it work even in a confined space. Nice to have it back in nearly one piece again!:)

Very direct acceleration, feels like the loud pedal is directly connected to the back wheels. Really fun!:D |

Looking awesome, there was some serious grin factor going on in that video

Arfon |

Nice one Chris :D

There was me thinking you were in hibernation again! |

Quote:

|

Took some pictures today as the light was good...

|

Even managed to make a foot rest in the tunnel out of the old mx5 ashtray! Waste not want not!

|

How is the mx5 pedal box working out for you ? It looks a little tight. Nice job , you will have the bodykit all on and buttoned up by lunch tomorrow then ?:eek:

|

Just noticed the diaganol running under the master cylinder, nice touch.

|

Quote:

Body on and all be finished by by 11:30am tomorrow me thinks!;) |

Quote:

|

You might be thinking of AdrianH for CNC chassis plates?

|

Oh yes that's the man, good bloke!

|

Finished my cycle wing mounts.

|

Got the car up on the ramps for the oil changes. Took some pictures while i was under there.

|

Looking good Chris :cool:

If you want I'll be happy to borrow those wheels and tyres for the summer and bed them in for you :) |

Quote:

|

I was under the car again this evening, tightening bolts, clearancing the handbrake cable amongst some other small jobs. While I was under there I took some more pictures of the speedo cable adapter which I got from a forum member in Australia, wish I new what it was off, works really well with my lowered floor and fluid pipe routing.

|

Isn't that the Toyota carolla AE86 adaptor that people were talking about on here about a year ago ? If it is, they are really bloody hard to get hold of a second hand one. My local Toyota dealership wants £96 for it !:eek:

|

WOW! I forget what I paid for it. I think mx5 mk2 clocks and the digital speedo drive is the way to go for future builds. It must be a cheaper option.

This is it before fitting.  |

Quote:

David |

|

|

|

Not a particularly productive day today, only adjusted the position of the handbrake lever to allow the fitting of the original cover, bent the lever over slightly too. I had to replace the existing cable as well as the old ones plastic covering was cracking off and I didn't want mr IVA to question its usability. Started to think about the centre cover and bent a small piece of ali then got bored and fed up and went in the house for a Sunday afternoon sleep! zzzZZZZZ!

|

I’ve been asked by a couple of people about why I’ve gone for 13” shocks on the front so I thought I might as well give an explanation on my build thread.

I have been working on the issue of the steering contacting wishbones on full droop. I thought I had resolved this by welding in rack limiters as you can see previously in my build thread. This seemed a good solution to prevent the steering on full lock contacting the front of the wishbones but after driving the car in a space large enough to complete a full turning circle it quickly became apparent that the amount of limiting done to resolve the contact issue was too much. I had something like a 19 metre turning circle which I estimated my using google earth lol! I also couldn’t make left turns without going into the opposite lane of traffic, a bit like a bus. So something had to be done. I know others have used 14” open shocks and rack limiters and have been happy with the results so I maybe just a one off due to my particular Saturn wishbones and the fact I was using Gaz 14” open shocks and not 13” with a 1” top hat. I don’t know, but my turning circle was unacceptable to me. As I was so far down the line with build and pretty much committed to using MX5 uprights and saturn wishbones (which I actually can’t see how you could improve for clearance without bending) I decided the issue was droop and I needed to limit that droop. Although I didn’t need to change the shocks to limit droop it seemed daft to keep them and not use their full travel. So as a quick test I fitted the 12” rear dampers but they weren’t able to give a correct ride height without a lot of preload and were giving me next to no droop at all and very little actual suspension. So I bought a set of 13” dampers to see were they would put me. The 13” dampers worked well I could achieve a good ride height without spring preload and also level wishbones, which I’d not been able to achieve with the 14” dampers and 400lb springs (without them being loose on full droop) I also had plenty of droop and active suspension but I was getting contact again at the very end of the steering lock at full droop. So the options were limit the steering lock again but only by a small amount this time or move the shock bracket on the wishbone to again limit droop a small amount and prevent contact. Limiting the steering was the easy solution but because I’d gone to all this effort I decided I might as well go the whole way and see were I ended up so off came the wishbone brackets and after a lot of careful measuring and estimation of ride height and droop I got them both tacked back on in the right position. It took three attempts to get the 2nd bracket in the correct location to get matching ride height and no wishbone contact. By moving the brackets outwards slightly I had changed the ride height the cars front frame bottom rail, it was only 85mm off the ground with no spring preload. I could of put preload into the spring but I thought this would be excessive so I ordered some 450lb springs, which seems like a lot but changing the angle of the shock had increased the leverage on the spring. I fitted the springs last night and with only hand tightening preload the car sits at a static ride height of 105mm. The springs can still be turned by hand when unloaded from the cars weight and the shock length with the cars weight on them is around 12” in length giving 1” of shock droop. Droop at the wheel though is around 1.5-2". The ride is supple yet firm, obviously I haven’t used the car in the real world so I shall keep hold of the 400lb springs for the time being just incase the ride is too firm at the front. If you can get away with rack limiting with the wishbones you're using and you're happy with it then that’s the solution. As I’ve said mine was just stupid so I had to do something.     |

|

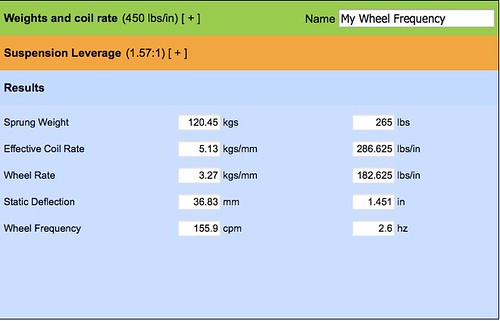

Oh also I forgot to mention I used this website to work out spring rates. Very useful! I worked out sprung and unsprung weight using our weight watchers glass bathroom scales! And they didn't break! Not the most accurate way to work out unsprung weight but it must be close.

http://www.hypercoils.com/spring-rat.../#.UymYXNwwgfp  I also rechecked the brake lines on full lock for clearance etc.   These mazda 323 brake lines with the brackets I've bodged together have worked out really well with the 1.8 brake carriers and the 13" wheels. I took the car down the neighbours driveway again this morning to check out the suspension difference. It was a limited test but it's not the most level of roads and there is one big bump in the road which I went over with the drivers side wheels fairly fast and I didn't really feel anything through my seat or steering wheel which was surprising. As I say only a limited test but promising. I also tested for steering self centring and it was completely AWOL guess I've lost the negative camber at the new ride height, I'll dial that back in at the weekend. Quick shot of the car in front of the neighbours greenhouses.  I went as fast as I could in the limited space and stamped on the brakes, slightly locking up the pass side front wheel, but no horrible sensation through the steering wheel or pulling. I think I can now move on to the 100mm ball test and get the front finished off mechanically. Is the 100mm ball test only with the wheels in the straight ahead position or do they do the test with full lock on as well? Anyone know? |

Quote:

Ideally you want to be calculating spring rate based on wheel rate, then adjusting ride height with pre-load and/or spring length. That calculator seems to do it ar5e about face and calculates spring rate based on ride height, then tells you what wheel rate you'll happen to end up with. Converting those figures to wheel frequency you'll have 135 cpm by my calculations. As a guide: 60 – 80 cpm Comfortable road car 80 – 100 cpm Sports road car 100 – 125 cpm Racing cars without wings 200 – 350 cpm Current racing cars with downforce |

I don't really know enough about it to comment John. So if your using 250lb springs on the front, how much preload in mm have you put into the spring?

|

I'm sure your right John, I just threw some numbers at this calculator and got these results.....

I noticed it didn't take into account damper angle though. http://www.racingaspirations.com/app...ncy-calculator This is fairly confusing!:confused: |

Quote:

With 250 springs I needed lots and lots of preload! Quote:

|

Quote:

If I suffer understeer due to the front spring rate, I had the mad idea today of making a rear ARB. But I'm going to forget about that for now, sounds like trouble!:) I can always try a lower spring rate and try preloading them. |

OK I've had a bit more of a play with these calculators and as one of them gives me a "motion ratio" of 0.411. see below..

MOTION RATIO Motion Ratio = (Dimension A / Dimension B) * sin(Spring Angle) The motion ratio is the mechanical advantage (lever ratio) that the wheel has over the spring in compressing it. I converted this for the Staniforth calculator to 2.43:1 and then my cpm dropped to 100.74cpm. I wasn't sure if this was correct but looking at the wheel rate the numbers are very similar. but one is described as "effective wheel rate" so I'm not sure what the difference is there. WHEEL RATE Effective Wheel Rate = Spring Rate * (Motion Ratio)2 Wheel Rate is the effective spring rate at the wheel, due to the leverage advantage the wheel has with respect to the spring on the control arm. Staniforth gives a wheel rate of 76.25lb/in whereas hypercoils gives an effective wheel rate of 72.55lb/in.  Does that look about right? I have no idea!:) |

Quote:

If I put 430lb/in into the Staniforth calculator i get 72.285lb/in. Same as hypercoils pretty much! |

Hmmm, you've got me doubting my calculations now.

I had been using the eibach equations here: http://eibach.com/america/en/motorsp...sion-worksheet However they seem to correct for shock angle slightly differently to others which seems to give very different results :confused: |

Well, I've had a couple of glasses of wine but, I'll have a look at that tomorrow!:confused: :D

|

| All times are GMT +1. The time now is 05:51 PM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.