|

Cawthray's Roadster Build

Hi everyone, thought it was about time to say hello. Been using the site for ages but never got round to registering and posting :rolleyes:

Anyhow me and my dad started building in May 2012 with an empty board and the book, this is our build so far (Pics are a bit big sorry)    Loads more pics and info on our blog if anyone is interested. Next job is water plumbing just waiting on parts. |

Throttle bodies or carbs ?

|

Bike bodies from an r6 I think. We had them given so not 100% we decided to extend the fuel rail and space them out rather than bending the manifold to match. It looked nicer and made things a bit easier.

|

Did not look right,I thought they were carbs and not at the right angle if you see what I mean.

Yellow is the colour !!;) |

Oh yea do the carbs have floats in or something so they have to be at a funny angle? these are deffo bodies ;)

|

Exactly that ,was going to mention it but you have TB's so no problem,good luck with it.

|

Nice looking build so far bud ....one thing is for sure.....its been tango'd alright:D :D

|

Cheers lol yes it has! hopefully going to tone it down a bit with more black bits.

|

Welcome to the funny farm, looking tidy won't be long before you will be looking for the dreaded test

Arfon |

Looked yellow to me,losing the plot :rolleyes:

|

Quote:

TT |

Quote:

|

It looks a different colour on every picture and different again in real life! Its RAL2009 if that helps.

We managed to start the water plumbing last night as we finally received the silicon hose.   Need to make some kind of supports for the pipes yet and get the header tank plumbed in too. |

Fantastic looking build!

Also, very impressive progress for only 2 posts ;) Looks likle the 2 of you are storming ahead with consistent progress, I will be keeping an interested eye on this. |

Yeronge !:p

Make sure the pipes have sort of flange on them or they blow off under pressure. |

Very nice looking build Tom :cool: congratulations, and I'm looking forward to see what is coming.

Did you make sure to use special silicone sleeves to connect your carbs to the manifold? They look to be the same kind as the hose you use for water to me. If it is so, they will not resist the fuel vapors. You need special silicone hoses, fuel resistant, which have a spacial inside layer (fluorine kind of component if I remember correctly). |

Looking good and your making great progress.

One thing I noticed is your single fixing for your roll bar stays. This was a iva fail early on for AshG so you may want to consider changing that. Also the rear brake lines are fowling the chassis, I don't know if that has been sorted since this pic.  |

Quote:

Quote:

Any ideas for how to do the roll bar stays didn't realise they had to have more than one fixing we just followed the book :confused: |

These were Ash's fails

You could do something like this, a second bit of triangulation the other side of the upright. A wider plate at the bottom of the stay and on the tub frame to take 2 bolts. Wouldn't require that much cutting/welding and would make sure there were no problems at iva. It may have been a 1 off but I would hate to take that chance.  20131130_155954_Wilfreds Grove by Series1Landy, on Flickr |

My rear stays have only one captive bolt fixing and no comment on it at IVA. It may be one of those things which is the personal preference of the tester.

|

The daft thing is,so long as your seat belt mounts comply with the regs there is nothing mandatory for a roll bar so its probably out of the remit of the tester to say yes or no to how it is fitted.

|

Quote:

But if your seatbelts are mounted onto any part of the roll bar, then the roll bar structure becomes a structural part of the safety system. hence you may need to show that it is adequate to take the load of the seatbelts in an accident + that any fixings are adequate + that any fixings are secured against vibration - e.g. lock nuts / spring washers. In particular taken from the manual :- In a severe accident, the seated occupant can exert huge loads upon their seatbelts (in the region of 1.5 tonnes for a 75kg person). Seatbelt anchorages together must withstand these large loads from the seatbelts. These loads in turn must be dissipated by the vehicle structure. In assessing the strength of the anchorages, it is essential to consider the vehicle structure in the immediate vicinity of the anchorage, and the parts of the vehicle structure into which the loads from the anchorages will be dissipated. These large loads will act in several directions as shown in Figure 1. All Vehicles What to look for: Evidence that anchorages in a vehicle of the same or a very similar type have been subjected to a seatbelt anchorage strength test to “European Standards” by a recognised authority. This may be acceptable where there is clear evidence that the structure is identical to the vehicle originally tested. Welding should appear neat and of good quality; whilst it is impossible to judge the quality of a weld just by looking at it, messy welding is rarely strong welding. Bolts used in structural areas should be of grade 8.8 or better. Such bolts will be marked 8.8 or 12.9 on the hexagonal head, however, cap-head bolts or 7/16" ( 11mm ) UNF seat belt anchorage bolts (with an anodised finish) not marked in this way may normally be considered to be of equivalent strength. Bolts should be M8 or larger. Threaded bushes should be welded (at both ends) through the tube, and not end mounted on the surface. (A threaded bush may be attached by its side surface to a structural component). Cause for Concern: Welds of poor appearance, gaps or visible lack of penetration. Anchorages in thin and/or flat panels with little stiffness or reinforcing structure or in thin walled tube. Low grade bolts (less than grade 8.8). Insufficient bolt capacity, e.g. number of bolts and/or diameter of bolts and Steel Chassis with Anchorages on Roll Cage (See Figure 3) What to look for: Triangulation and bracing which will provide strength and spread the loads effectively into the chassis. The joint where the roll cage joins the chassis and the chassis itself must be sufficiently strong to withstand the loads from the anchorages. Upper anchorage must be adequately braced from near the anchorage to strong areas of the chassis. Threaded seatbelt anchorage fastening should be welded into tubes or onto plates of sufficient thickness. Bolted joints joining the cage to the chassis and parts of the cage to each other should be of sufficient strength. |

Agreed David,if you look at the angle the book roll bar rear supports act's in, the flimsy rear stay fitted to the original metal work for the ally rear panel it could pull forward in an extreme accident (god forbid),it should go to the diff cage or lower chassis to give it strength.

The seat belt plates should also be folded in to make a stronger base to weld to the chassis. It's been said a hundred times before on here its how the manual is interpreted and not how its written. |

Wow cheers for all the info fellas. I think what we might do is grind this bit back and just weld it round. Only thing is if we do that the stays will be welded to the chassis obviously and the main bit is bolted in. I know its difficult to say for sure but does anyone think that will matter for Mr IVA?

|

Quote:

Also (and I don't say this because I sell brake lines, don't misunderstand me, it is just my opinion I want to give you about that) but I think the bend of the flexi lines on the calliper side is definitely too tight and not natural. The stainless braid will force and pull on the ferrule (and actually even more when the car will be on wheels), which in time, can lead to a failure of the line. The straight fittings you have are good for drum set-up, as the wheel cylinder's port is almost perpendicular to the longitudinal axis, but with these callipers, with the port on top, a 45° or even a 90° fitting would have been much preferable. Sorry about all these comments Tom, it sounds like we are just pointing problems and give you critics. That is not the case: your build looks very nice, and the job you did with your father is just great I think. I thought I would just give you my opinion about these two points, but let me tell you that I think that the rest of your build is stunning :cool: Hope this will help:) |

Before you do anything I would give your IVA inspector a call and have a chat with him. Some have passed with just the single point, I put two in to be sure. It is useful to be able to remove your hoop.

|

Quote:

Didnt really think to ring the IVA inspector good idea ;) |

I did exactly that regarding my harnesses. Very helpful and gave me a few suggestions too

|

Quote:

The plates are flush with the top rail though - which means I need to butcher my Equinox back end to get it to fit round - the grp moulding 'wraps' over the top very neatly .... Not sure whether to rethink the whole lot now... |

How do chaps, not much to report really at the mo and not got any further with the potential roll cage stay issue either BUT, we have just ordered a microsquirt ecu so should hopefully have her running soon :D pics and vids coming at the weekend if all goes to plan.

|

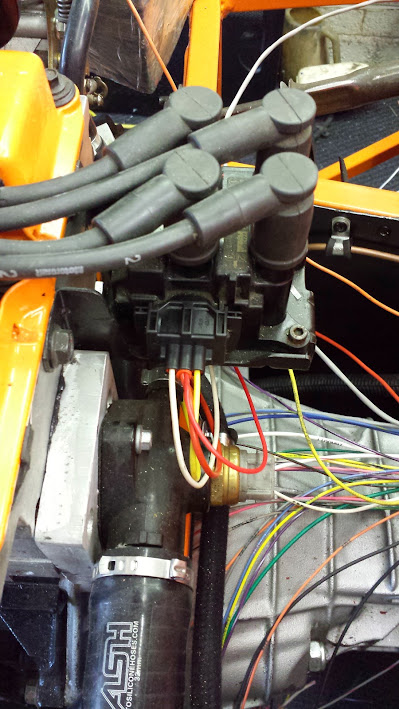

Well safe to say things didn't quite go to plan. We got the wiring all done but no spark :confused: haven't had chance to have a proper look over it all yet but reading up it seems quite common so we have a few things to double check. We're using an edis 4 unit with a microsquirt v3 ecu.

Obviously the earths on this pic are just temp. |

Well the good news is that we have found out why we don't have a spark, the bad news is the reason we don't have a spark! Turns out our engine was from an automatic so the crank sensor housing is different to the manual. The housing is on the engine behind the flywheel so engine has to come out again :(

This thread shows the difference better than i can explain. http://www.locostbuilders.co.uk/view...php?tid=182948 |

How do chaps long time no post. Been busy with the build and finally got her running! :D

I emailed approvals@vosa.gsi.gov.uk to ask about the possible roll bar problem and this is the response. Good afternoon Tom, The reason for the slight confusion here is that the requirements for a roll bar differ dramatically from that of a seat belt anchorage point. As a roll bar, the IVA examination simply needs to establish that the bar is suitably attached to the vehicle structure. However, if you then attach a seat belt mounting point to a roll bar, it becomes a seat belt anchorage and is then assessed as such. The main requirement for a seat belt anchorage is that it can withstand a pulling force in the region of 1.5 tonnes per anchorage. Therefore, this bar will be expected to withstand more than 3 tonnes of force, as it has two anchorage points fitted. Obviously, this will require a very substantial mounting arrangement to acheive that. A very useful guide to seat belt anchorage strength assesment can be found at Annex 3 in section 19 (Seat Belt Anchorages) of the IVA M1 manual. I have therefore attached a link to the latest version of the guide below: IVA MANUALS - https://www.gov.uk/vehicle-approval/...proval-manuals So still not really any clearer i think as long as its solid enough we should be ok also going to make sure we have this email when we go for the test so we can at least say we have looked into it and interpreted it as been ok. Other than that we've just been plodding on with the electrics. |

pleased to see the tango machine is still evolving:)

|

| All times are GMT +1. The time now is 07:28 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.