|

Playing with Tig

Unable to make Exeter show ( again ) :(

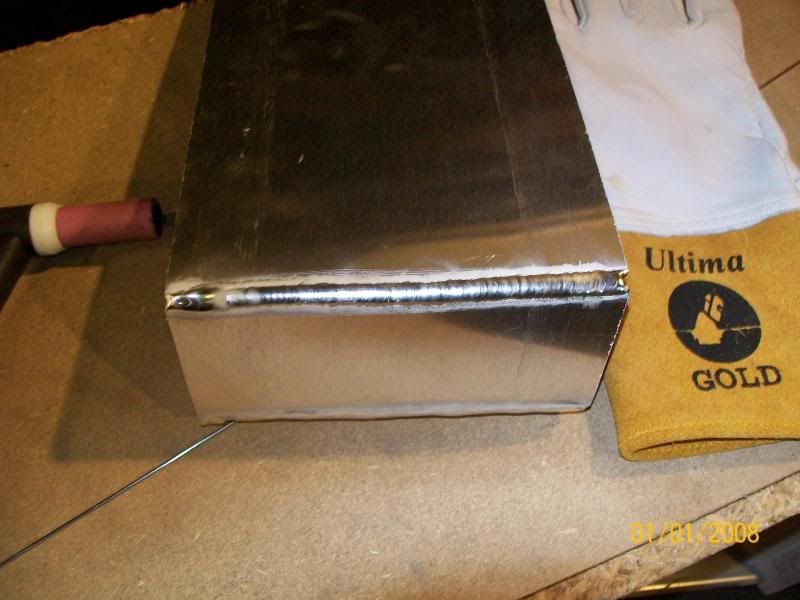

I have been sulking away in the workshop looking for easy sit down jobs. Junior gave me a hand to fit the alloy rear panel & I am part way through making the fuel tank Recently bought an AC Tig welder, inverter type It works well for a cheap Ching-Chong bit of kit. Now, I have not tig welded alloy for almost 25 years :eek: & was pleased how quickly I got the hang of things once more. Here is a test piece I done before starting the tank  2mm alloy sheet, corner weld, no filler rod needed, 2.4mm Zirc tungsten, 110 amp ( ish ), argon flow 10L, number 8 cup. Here's another of the partly made tank fitted in its place.  Baffle plates & endcaps next Oh....Get Junior to take me on a jolly to find some alloy tube for the tank fittings !! |

That looks great id be very suprised if that leaked

Ray:) |

How do you get away with no filler rod?

|

good stuff bonzo,

and very neat fit. i was looking at those chinese tig's. cheap as chips. wat make is yours? |

no filler rod actually makes it easier as your not introducing a different metal

sometimes its best to cut thin strips of the parent metal when welding and fuse them together you can tig copper and brass using this method sometimes adding a filler rod actually puts impurities into the weld all my own opinion Ray:) |

Hey Ronnie that looks nice,

you open for orders????;) |

oh ok I see now just lay the strip over the join and fuse it all together or use the strip like filler rod?

|

you can do either

but i think ronnie just fused the two pieces together |

I seldom find the need to use filler rod on a close fitting corner joint ( Must be tight with no visible gaps ) ;)

I think it is purely to do with the correct set up & weld procedure. Yes I took a gamble on a Cheap Chinese import, I know that some of them have a dreadfull reputation. The price was worth the risk (ish) :eek: The model I bought was a WSE200. ( "Giant" Branded set ) 200 amp AC/DC inverter. 60% duty cycle HF start Pre & post gas Slope up & slope down Cleaning width adjustment £395 including free delivery & foot controller It has a surprisingly smooth AC output & very fine current controll. Time will tell as to wether it lasts the distance or not :D If it does all of the work planned for my build, it'll owe me nothing !! Could of had a used commercial set for not a lot more but was unable to locate a good second hand unit locally ( Fetch silly money down here ) :rolleyes: |

Yep you are correct Ray. I just fused the edges together. :)

Filler rod can be a bit of a nuisance at times........ If you are not extra careful & if too much filler rod is introduced to the weld pool, the pool tends to flow too quickly & can cause poor root penetration or hidden cavitys in the weld. ;) |

Man's a proffesional !:D

|

Quote:

Ronnie that looks stunning :cool: cheers andy ps... the talk about root & cavities reminds me i need to go to the dentist :eek: |

Quote:

Mind you, I wouldn't feel a thing :D .....Guess where I would put the earth clamp :D That reminds me of two scottish, gay dentists......Ben Doon & Phil McCavity :o Custom tanks, may very well be on the cards !! |

Quote:

makes me think of the 2 celebs in the jungle, the interior decorators..... the fact that one of them is called "Just in " ....makes me laugh but then again i,m a sad git :D :D again, nice tig work Ronnie. cheers andy |

If your thinking about making more tanks, i would order one from you, :D

Quote:

|

Here's another pic of the inside of the tank, not very clear as the cameras flash plays havoc with the image quality ;)

Just about optimum root penetration. If I were to be absolutely honest, a couple of more amps wouldn't have hurt But then the risk of blowing through is a lot greater :)  I'll post some more pics when I have fitted the baffles ;) |

Use some electrical tape and tape some newspaper to the inside of the tank top and bottom leaving just 10mm either side of the weld this should help get a better pic without the flash.

|

Quote:

Top tip that man :) Hang on a mo.....................I can't afford newspaper & tape, I have just blown my wonga on new kit :eek: :D :D |

I have just received the same TIG set set as you Ronnie as a birthday presant and for some thing to learn with I can't fault it for easy of use as a novice. I had a quick play with the DC setting as I currently only have Argo sheild to play with so a bottle of argon is on order.

Just waiting for the rest of the new toy to arrive such as argon regulator,gas pipe,new mask,better gloves, mild steel rods,stainless rods etc...this TIG lark aint cheap is it! |

Quote:

Especially when you get sweet talked into buying a new welding screen when you only went in for a tube of filler rods :D That's the trouble with an account. so, so tempting to go beserk whilst at BOC. !!?? I'm sure that you will get the hang of it quickly. One of the best bits of advice i can remember being given. " Don't let the weld pool rush you " ... " Be the boss of the weld pool & make it work at your pace " :) If things start getting a little hot. Stop & move a few inches further along, then do a bit more. On the tank, I held the joints in place with a small strip of light gauge alloy angle & clamps. ( Remove once tacked ) I then placed a few small tack welds evenly spaced ( about 150mm apart ). The use of filler rod will make tacking easier. Just enough to catch the two edges ( Not looking for full penetration at this stage ) Once the tank was all tacked up I started to fully weld the seams. Starting at the right hand end of the joint. Slowly fused the edges together for a distance of 50-75mm, Flip the tank round & do the other end. Finally a couple of small sections in the middle of the seam. ( Will help to prevent heat build up & distortion ) If the tacks are large, fettle back with a file or flap disk that is saved only for alloy use. Once the tacks are reduced the weld pool will soon melt them away. ;) May I ask, What did you think of the Plasma cutter as I am temped to buy one of those as well. |

It's interesting to see how you are getting on with this machine.

I have seriously considered buying myself one, but was worried about the Chinese quality. Having said that, I bought a Chinese Plasma Cutter and it has been fine. Obviously, I am not expecting these things to have the longevity of a Miller/Boc/Murex etc. but for the price they can't be too bad. The only thing is, the only job I need a TIG for is making the ally fuel tank. Seems crazy banging £400+ on a tool for one job. |

Quote:

|

Heya Ronnie

Iv been looking at getting myself a tig set for a wile now, and like has already been mensioned my main consurn is the build quality and life of the kit. Were abouts did you get yours from? make model etc? £400 definetly sounds nice compared to the £1600 one im corently looking at Chears Tilly |

Quote:

Quote:

That a very good price considering it includes delivery & footpedal |

May I ask, What did you think of the Plasma cutter as I am temped to buy one of those as well.[/quote]

The plasma is cheap and cheerful at best, you get what you pay for! It works well and cuts very clean up to 3-4mm but it's fussy about air pressure and speed. On thicker material it eats consumables like to would'nt believe, I now know why there sold in bumper packs. As for cutting up to 10mm I think thats abit out of it's reach. You can cut shapes that you could'nt do with a 4.5-5inch grinder but if your cutting straight lines in any thing over 5mm I'd still reach for the 9inch grinder as it's just easier. Edit How ever after just two uses the sodding thing has packed up, switch it on it goes into 'safe mode' will not fire up at all. |

This sounds similar to what Bonzo has ,listed on ebay.uk.. even cheaper!!

http://cgi.ebay.co.uk/TIG-WELDER-MMA...item2c51e0a9d2 |

Quote:

Thats the same seller but a diferent item, that one is a DC only inverer ;) This is his current offering WSE 200 AC/DC I bought when he had a weekend special....Free delivery & foot controller. To be honest, it was the free foot controller that sold it too me :rolleyes: Does that make me a sad un or what !!?? :o I did think that that might be the case with the plasma cutter. 10mm a bit optomistc & touch start will eat the consumables !! Hark at me talking about something that i have never used ( Plasma cutter ) All courtesy of BOC !!?? Maybe i'll stick to Bertie the burner & my trusty jigsaw :D |

Quote:

When it turned up, I had the thing going in about 10 mintues. HF start which is cool Drag tip as well, which makes it easier As for 14mm, you 'might' get a severance cut on 10mm, but would take some cleaning up after. 6mm is a bit jagged, might just need more practice 3mm no problems 1mm - how fast can you mvoe the torch:D |

| All times are GMT +1. The time now is 08:47 AM. |

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.