Quote:

Originally Posted by Talonmotorsport

If you have some material spare say 2 bits about 200-300mm long prep and weld them in to a T shape. Allow to go cold and abuse it vigorously while clamped in a very good vice bolted to some thing very solid, your aiming for as much leaverage as you can find. If the weld comes away from the material looking like a steel scab it's naff and you need to turn the heat up, if there is enough penetration the material will tear around the welds if at all if using 2mm.

|

Once thanks a lot, I just read that in the FAQ he he

Bit of an update:

Started to cut and tack the BR's so I'll let some photos do the talking for once, and I'll be posting loads of photos throughout my build so watch this space.

Notes I made proper legs for the table, I put up a screen in front of the westie as I can't move it and I forgot to put on my steel toe caps tonight and nearly drop a length of steel on them, whoops.

Could not resit the Brum Brum picture:

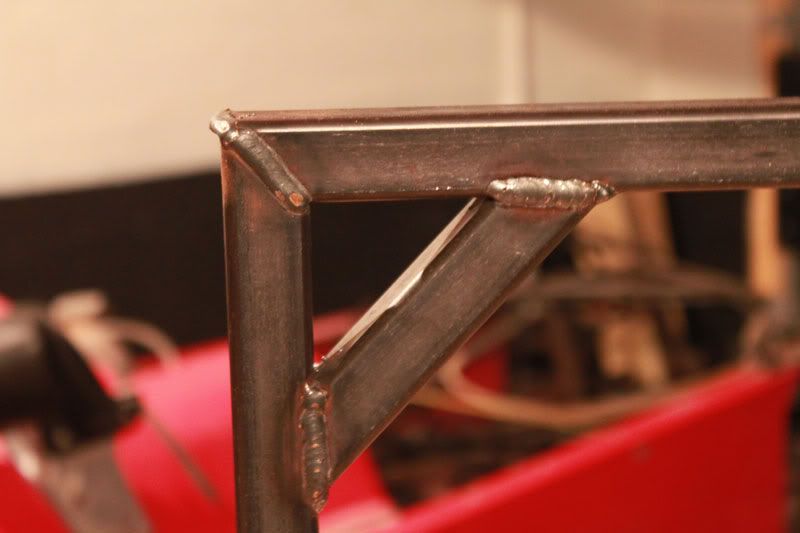

Finally some test welds (forgot to prep them properly i.e just cut and welded and I'll make re do it with a T section as I think I made the corner to strong with the brace), I smacked the shit (excuse the language) out of it and just bent it a wee bit. Also can you give some tips on my welding just by looking at this picture. If you need other pictures I can get them over the weekend.

So that's it for now. I very nearly bought a flat pack kit but you know what building it myself setting up the saw etc is hard work but when I start to see it come together the feeling is just amazing when I stand back and take a look at it even with how little I have done this evening.

Cheers all for your help and support, gods knows I'll need loads of it.