Quote:

Originally Posted by skov

Nice start

Not sure about your donor though, you might find it a bit underpowered |

Cheers skov, yes I may boost the power with an engine at some point, child labour although cheap is probably illegal! Got my liner changed but it hasn't made much difference which is good to know I suppose, just means I have no excuses for crappy welds!

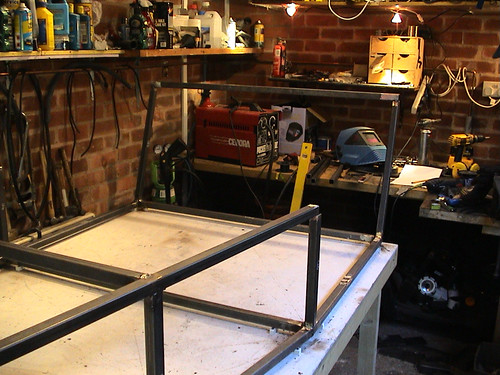

Been spending most of my time measuring, "Just off out to the garage for a bit of a measure dear!" You really do spend 90% of the time measuring. Couldn't figure how I was going to get an accurate 17˚ rake to the SB1s so I got out my protractor and spent 20 minutes making a template out of 3mm steel plate, also I have found computer hard drive magnets are excellent for holding the steels in place whilst tack welding. Got SB2 in place too and before moving on I fully welded all 3 in place and dressed the welds I have yet to fit the second inner pair of SB1s.

Even though I fully welded the BR frame, welding in the uprights caused the back of the BR frame to lift by 3mm so I had to spend some time using weld heat on the underside to bring it back down again.

Still enjoying the process. Which is why i wanted to do this project, driving it will just be a bonus.