This method has never failed me from a small bolt in an ali casting to a monster in some farm equipment.

A small 8mm bolt sheared off in an old srap head just to play with.

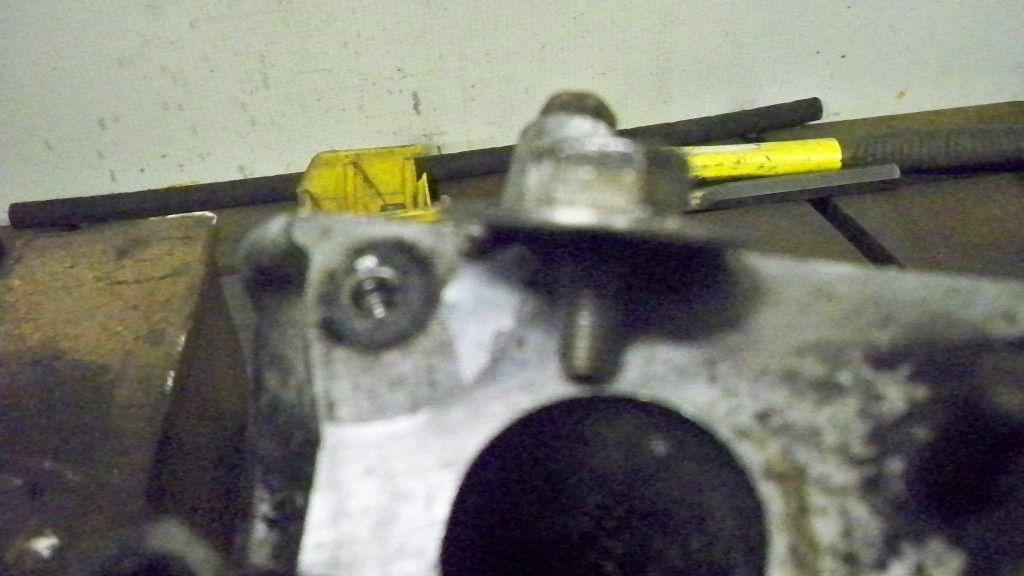

Clean up the head of the stud as best you can and place a large washer over the stud but make sure the hole in the washer is no bigger than the stud . Then grab the mig ,up the amps and turn down the wire feed and get a good burn onto the stud and washer

Then get a large nut with say a 10 or 12 mm hole in and weld through the middle onto the washer.

Then unscrew the little blighter.

Da DAAAAAAAA

This will never fail , just take you time and make sure all is clean. I think the heat from the welding is the reason they come out so easy this way. dont forget to disconnect the battery if welding on the vehicle.

Edit. it took longer to type all this than to do the job.

Bob