|

|

#1

|

||||

|

||||

|

Unable to make Exeter show ( again )

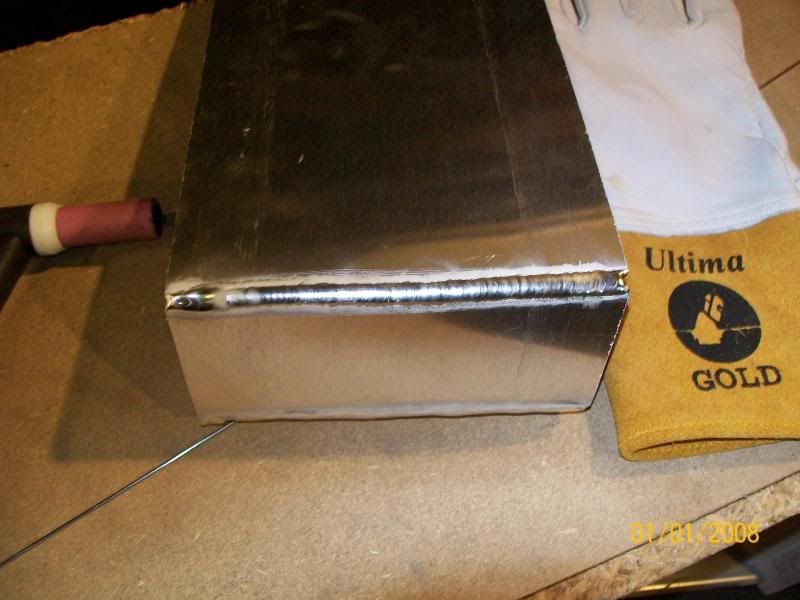

I have been sulking away in the workshop looking for easy sit down jobs. Junior gave me a hand to fit the alloy rear panel & I am part way through making the fuel tank Recently bought an AC Tig welder, inverter type It works well for a cheap Ching-Chong bit of kit. Now, I have not tig welded alloy for almost 25 years  & was pleased how quickly I got the hang of things once more. & was pleased how quickly I got the hang of things once more.Here is a test piece I done before starting the tank  2mm alloy sheet, corner weld, no filler rod needed, 2.4mm Zirc tungsten, 110 amp ( ish ), argon flow 10L, number 8 cup. Here's another of the partly made tank fitted in its place.  Baffle plates & endcaps next Oh....Get Junior to take me on a jolly to find some alloy tube for the tank fittings !!

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk |

|

#2

|

||||

|

||||

|

That looks great id be very suprised if that leaked

Ray  |

|

#3

|

||||

|

||||

|

How do you get away with no filler rod?

__________________

Website http://www.talonmotorfabrication.co.uk/ Direct email phil@talonmotorfabrication.co.uk talonmotorfabrication@gmail.com Mobile office hours 07514098334 |

|

#4

|

|||

|

|||

|

good stuff bonzo,

and very neat fit. i was looking at those chinese tig's. cheap as chips. wat make is yours?

__________________

http://picasaweb.google.com/davielad |

|

#5

|

||||

|

||||

|

no filler rod actually makes it easier as your not introducing a different metal

sometimes its best to cut thin strips of the parent metal when welding and fuse them together you can tig copper and brass using this method sometimes adding a filler rod actually puts impurities into the weld all my own opinion Ray  |

|

#6

|

||||

|

||||

|

Hey Ronnie that looks nice,

you open for orders????  |

|

#7

|

||||

|

||||

|

oh ok I see now just lay the strip over the join and fuse it all together or use the strip like filler rod?

__________________

Website http://www.talonmotorfabrication.co.uk/ Direct email phil@talonmotorfabrication.co.uk talonmotorfabrication@gmail.com Mobile office hours 07514098334 |

|

#8

|

||||

|

||||

|

you can do either

but i think ronnie just fused the two pieces together |

|

#9

|

||||

|

||||

|

I seldom find the need to use filler rod on a close fitting corner joint ( Must be tight with no visible gaps )

I think it is purely to do with the correct set up & weld procedure. Yes I took a gamble on a Cheap Chinese import, I know that some of them have a dreadfull reputation. The price was worth the risk (ish)  The model I bought was a WSE200. ( "Giant" Branded set ) 200 amp AC/DC inverter. 60% duty cycle HF start Pre & post gas Slope up & slope down Cleaning width adjustment £395 including free delivery & foot controller It has a surprisingly smooth AC output & very fine current controll. Time will tell as to wether it lasts the distance or not  If it does all of the work planned for my build, it'll owe me nothing !! Could of had a used commercial set for not a lot more but was unable to locate a good second hand unit locally ( Fetch silly money down here )

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk Last edited by Bonzo : 22nd November 2009 at 08:29 PM. Reason: Edit text |

|

#10

|

||||

|

||||

|

Yep you are correct Ray. I just fused the edges together.

Filler rod can be a bit of a nuisance at times........ If you are not extra careful & if too much filler rod is introduced to the weld pool, the pool tends to flow too quickly & can cause poor root penetration or hidden cavitys in the weld.

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk |

|

| Thread Tools | |

| Display Modes | |

|

|