|

|

|

|

#1

|

|||

|

|||

|

As some of you may remember, I've already got a build thread of sorts entitled "New build" or something. Considering the length of time I've been working on it I figured a change of name was in order

In my defence though, I only get to work on it a couple of hours on the odd weekend - I live in Reading, the car is in Bristol! In my defence though, I only get to work on it a couple of hours on the odd weekend - I live in Reading, the car is in Bristol!The story so far: I bought the car in summer 2013 as an unfinished project - having experienced my share of chassis building in the past I felt no need to go through it again! Also having a lot of the parts (hubs etc.) saved me from having to source them or get a donor.   I then set about strengthening and modifying the chassis to accommodate my choice of engine - the BMW 2.8 liter M52B28 straight six.

__________________

If dysfunction is a function, then I must be some kind of genius. |

|

#2

|

|||

|

|||

|

__________________

If dysfunction is a function, then I must be some kind of genius. |

|

#3

|

|||

|

|||

|

I then started sorting the brakes and the steering. And decided to change the engine to a V6 from a Jag... only a minor alteration

__________________

If dysfunction is a function, then I must be some kind of genius. |

|

#4

|

|||

|

|||

|

__________________

If dysfunction is a function, then I must be some kind of genius. |

|

#5

|

|||

|

|||

|

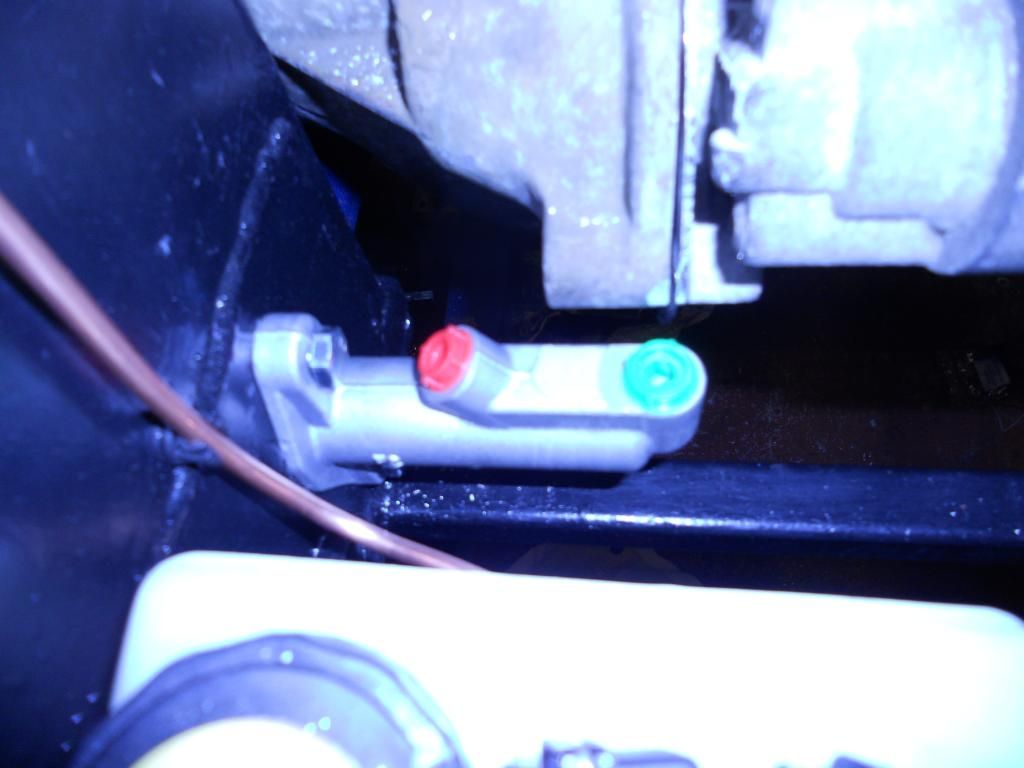

And that brings me to today; I installed all the freshly painted suspension and braking components, then started to bleed the brakes, only to find the bleed nipples I'd fitted to the front calipers are too short

Stupid mistake but a bit of an annoyance! Stupid mistake but a bit of an annoyance!

__________________

If dysfunction is a function, then I must be some kind of genius. Last edited by Badger : 20th January 2015 at 07:52 PM. |

|

#6

|

|||

|

|||

|

So I had a quick look at swapping over the dual mass flywheel on the V6 to one from an ST200, which I had hoped would fit. Short answer to that is "No".

The ring gear is the wrong pitch, it is thinner (needs shorter bolts), and because it is thinner I don't think the clutch splines will engage properly with the transmission and the clutch bearing will not reach the clutch to disengage it. Scrub that idea     Also no spigot bearing, the dowels to align with the clutch pressure plate are too small... this represents a large amount of work to get it going, and to be frank I don't think I can afford it!

__________________

If dysfunction is a function, then I must be some kind of genius. Last edited by Badger : 19th January 2015 at 12:32 AM. |

|

#7

|

|||

|

|||

|

To catch up on my build progress slightly (as I find more pictures on my computer):

To mount the gearbox I chocked the gearbox into position and measured the angle between the drive flange and the differential - about 0.5 degrees vertical and bang on horizontal the first try! I then welded a crush tube into a tube cut to fit into the drive tunnel, screwed it onto the bottom of the gearbox and tacked it in place. As there was a screwed in adapter that stuck out from the bottom of the Jag gearbox there was much room for a soft mount - here it is with the tube tacked in and a shim:  To fix this I removed the adapter and cut off the bottom so that it was flush with the bottom of the gearbox. I then cleaned the threads and screwed it back in with a healthy dollop of high strength Loctite. I then cast a Shore 70 polyurethane block and drilled a hole down the middle for the bolt. The bolt passed up through the crush tube, through the poly block and into the gearbox with enough space for a locking nut on top - result!  I have some doubts whether the poly is hard enough, and I wondered whether I should have bonded some metal plates onto the surfaces, however I reckon it is good enough for now.

__________________

If dysfunction is a function, then I must be some kind of genius. |

|

#8

|

|||

|

|||

|

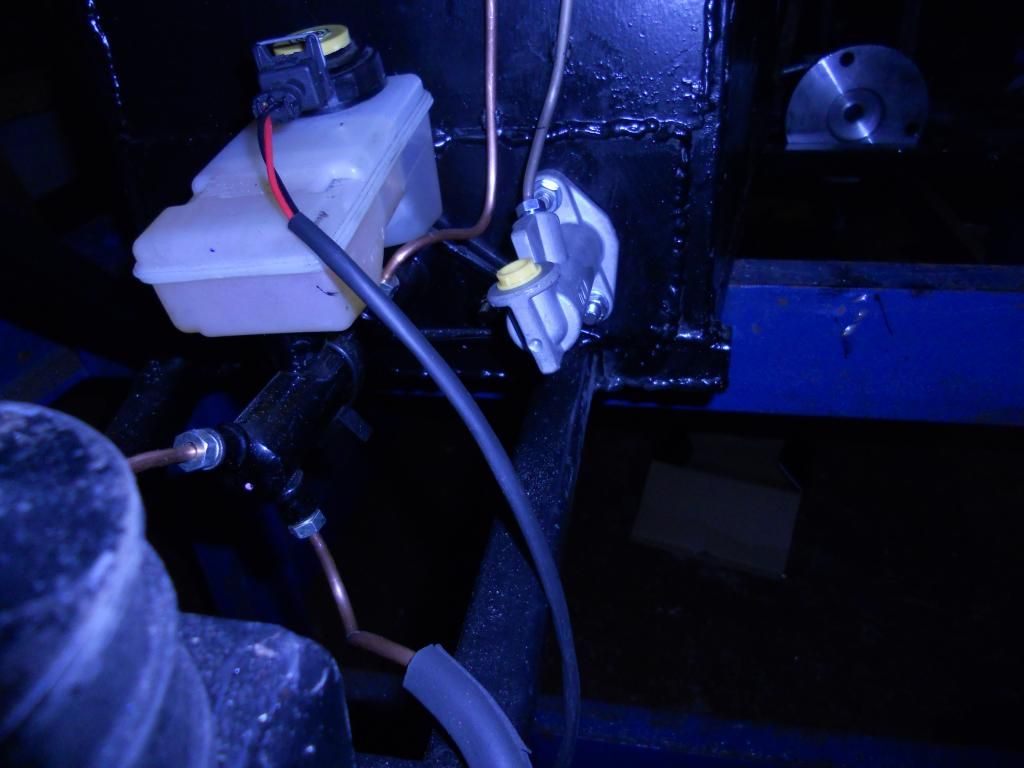

The car came with a pedal box as designed by Sylvain, which I was very happy with. I've had to modify it for a hydraulic clutch, and I've opted to weld it in situ. With the brake and clutch master cylinders mounted, this is now complete until I get around to accelerator linkages.

I had to tilt the clutch master cylinder slightly to improve clearance with the engine starter motor, which I felt was a bit close for comfort (I'd originally positioned it for the BMW engine which was fine)

__________________

If dysfunction is a function, then I must be some kind of genius. |

|

#9

|

|||

|

|||

|

And my final bit of verbosity for the evening, I finished off the handbrake mechanism on Saturday evening - though all the cables work, the pistons do not seem to move. I'm hoping this is because I wound them all the way in when I refurbished the calipers and they need to be pushed out by brake fluid for the auto adjust... I hope!

Custom handbrake adjuster bar, a shameful copy of one I saw on Locost Builders. Needs a lick of paint!  Handbrake in position - I originally looked at mounting this further forwards as I find it hard to get hold of it in its current position, but unfortunately it started interfering with other things and had to go back to it's designed position. Ah well!  Finally my slightly kinky clutch pipe - not so sure about this one, I may need to rethink it a bit. There's plenty of clearance between it and the brake pipes behind it (as shown by the foam padding falling down!) but I just keep thinking there is a neater way...

__________________

If dysfunction is a function, then I must be some kind of genius. |

|

#10

|

|||

|

|||

|

Looking good, dont no how i missed your thread, must be the forum as it never shows up new posts on new posts

|

|

| Thread Tools | |

| Display Modes | |

|

|