|

|

|

|

#1

|

|||

|

|||

|

I have asked this question on the 'other' forum without getting a definite answer.

Basically, I want to use Cortina front uprights. These seem to be getting harder to track down, and fetching good money. And about 4 years ago there was some discussion by someone called Rorty about fabricating some Cortina pattern front uprights from lasered and welded parts and a bolt in stub axle. Which really appeals to me. But since those initial posts it seems no one has really made any.  We accept the fact that the rears are fabricated, so surely the fronts can be too. But this leads me on to think about instead of fabricating an upright to match the Cortina geometry and have to modify the Book wishbones to suit, why not fabricate front uprights to replicate the Sierra uprights with the top location built to not have to use the mushroom inserts. I have access to materials, laser, presses and I although I can weld, I am hoping to get onto a proper welding training course soon. So, throwing this out to the jury, why shouldn't this be done? I want to scratch build as much as I can, and fabricating front uprights seems like it should be possible. The only thing I have not managed to do is find someone thats already done it. Last edited by Balidey : 20th August 2009 at 09:23 AM. |

|

#2

|

|||

|

|||

|

Nothing to stop you making your own and nice drawings,is it not easier to buy them already made with the right geometery and I would think much cheaper in the long run.

Dont get me wrong I am not peeing on the bonfire,anything to make life easier. |

|

#3

|

|||

|

|||

|

Weren't there lightweight alternative made by a firm? Raceleda springs to mind.

If they can do it, then there is no reason you can't, assuming correct design/materials/fabrication etc. I think that the forces involved in the front uprights are 'probably' higher than those in the rear. The rear is basically a glorified hub carrier/suspension pivot. The front also has to take the cornering forces. Flyerncle is right about the cost/hassle factor. I did see a set of cortina uprights on Eblag for £50 the other day, no idea what they ended for. Sean Last edited by londonsean69 : 20th August 2009 at 07:32 PM. |

|

#4

|

|||

|

|||

|

I could not remember, but Raceleda one's are the dogs bits and easily available. About £300 possibly.

|

|

#5

|

||||

|

||||

|

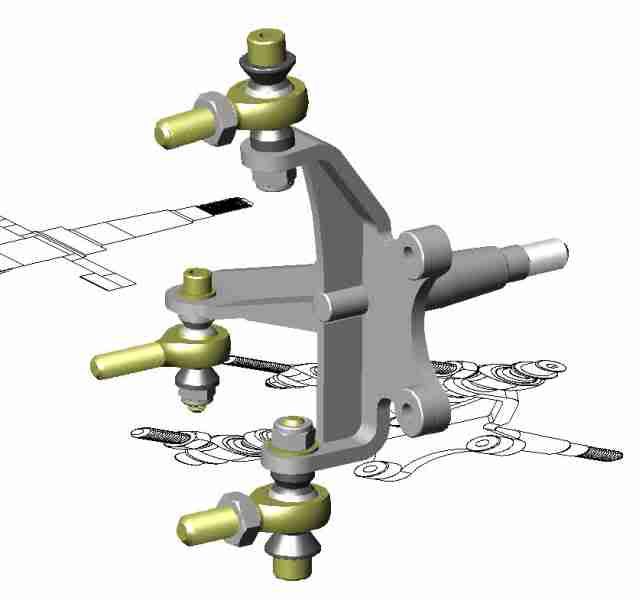

The light weight uprights as in the cad drawings are used in grass track specials and heavily modded class 5+7 saloons. www.drdracing.co.uk/Chassis_Components.php These are £40 each plus ally escort type hubs £40 each. So question is if there that cheap why make them?

|

|

#6

|

|||

|

|||

|

Cheap is a relative term when I plan to scratch build almost everything.

£40 each upright, plus £40 each hub, plus about £15 postage.£175. Cortina hubs are about £80 to £100 a pair. Sierra ones about half that, but requiring mushrooms. From what I have read the best uprights to use are the older Triumph design, but again are harder to find and fetch more money. Fabricated uprights will cost time only as I have use of materials, laser, mill, lathe, welding, blasting. And I can tailor them to give me the geometry I need. What I hadn't seen is any evidence of fabricated items, but those links above for the autograss ones confirm that they are made, and I have seen the abuse that some og those cars get  so I am more than happy to attempt to make my own. I think. so I am more than happy to attempt to make my own. I think.And the 'hassle' factor shouldn't come into it, it should be the 'fun' and 'rewarding' factors. Isn't this why we build cars? not to have hassle, but to enjoy the process of it, and to save some cash too. And the smaller items I can make (uprights, wishbones etc) I can tackle sooner, where are the chassis is going to be harder to hide from my wife Last edited by Balidey : 20th August 2009 at 10:12 PM. |

|

| Thread Tools | |

| Display Modes | |

|

|