|

|

#1

|

||||

|

||||

|

Unable to make Exeter show ( again )

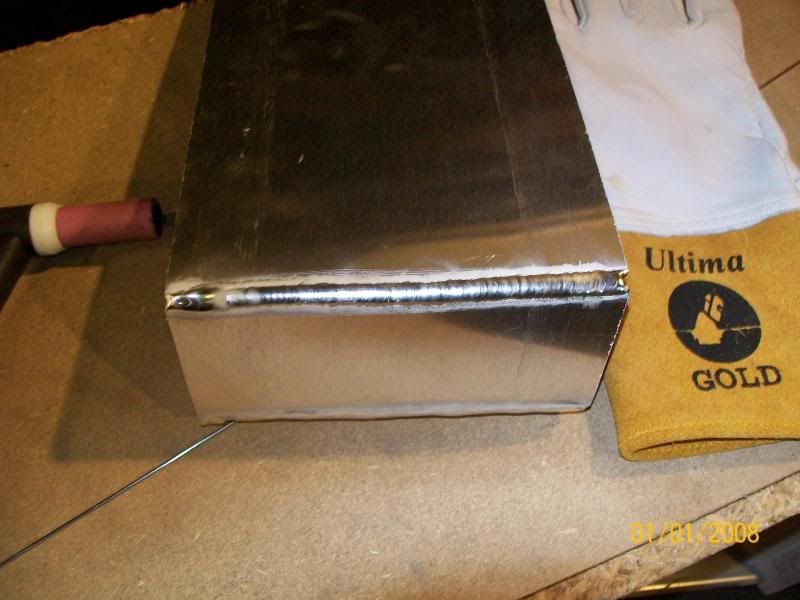

I have been sulking away in the workshop looking for easy sit down jobs. Junior gave me a hand to fit the alloy rear panel & I am part way through making the fuel tank Recently bought an AC Tig welder, inverter type It works well for a cheap Ching-Chong bit of kit. Now, I have not tig welded alloy for almost 25 years  & was pleased how quickly I got the hang of things once more. & was pleased how quickly I got the hang of things once more.Here is a test piece I done before starting the tank  2mm alloy sheet, corner weld, no filler rod needed, 2.4mm Zirc tungsten, 110 amp ( ish ), argon flow 10L, number 8 cup. Here's another of the partly made tank fitted in its place.  Baffle plates & endcaps next Oh....Get Junior to take me on a jolly to find some alloy tube for the tank fittings !!

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk |

| Thread Tools | |

| Display Modes | |

|

|