|

|

#361

|

||||

|

||||

|

That's such an amazing job you did on the Engine Kev, incredible! Congratulations, really nice and I look forward to see it running

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://cafrazx550.blogspot.com/ |

|

#362

|

||||

|

||||

|

Very nice work on that engine indeed sir....

It'll almost be a shame (sorry a crime) to cover it up...LOL  I guess you just keep moving the bar upwards on everything you do... Keep up the good work.

__________________

Any intelligent fool can make things bigger and more complex... It takes a touch of genius - and a lot of courage to move in the opposite direction. Albert Einstein http://s1199.photobucket.com/albums/aa472/JohnoSS1/ Johno |

|

#363

|

|||

|

|||

|

Quote:

bob

__________________

When The Results Disagree With The Theory: Believe The Results And Invent A New Theory If I had two brains I,d still be a halfwit The cave http://s1116.photobucket.com/user/my...deshow/mancave The build http://www.haynes.co.uk/forums/showthread.php?t=12669 |

|

#364

|

||||

|

||||

|

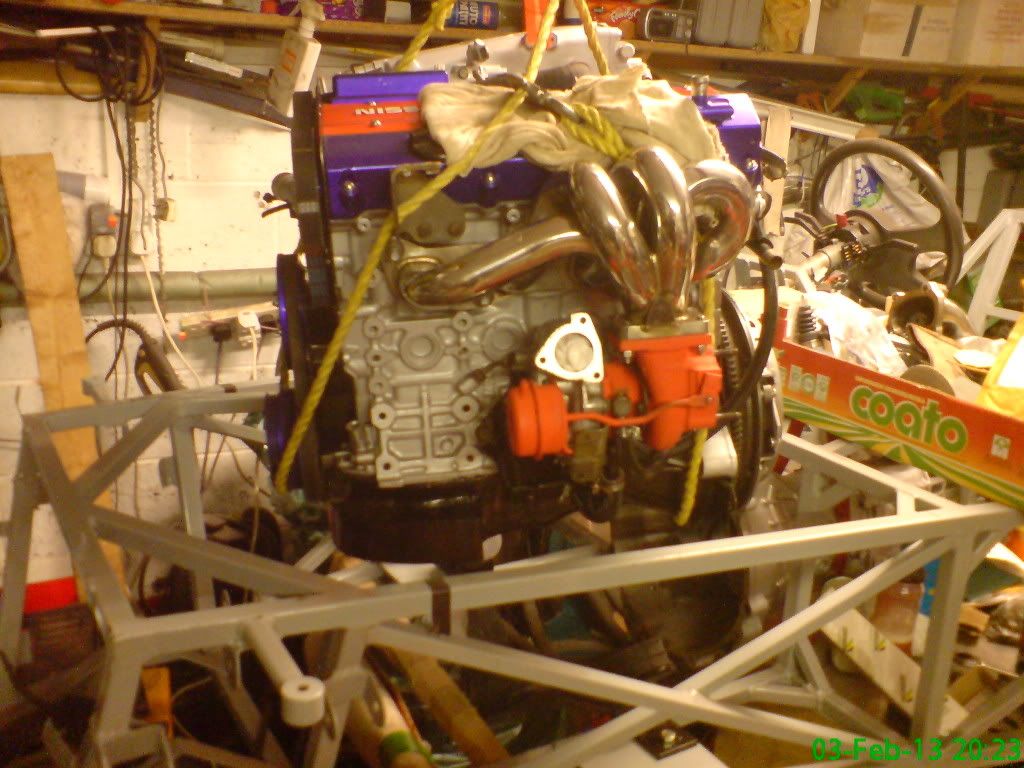

Again....thanks guys.....needed a few days off from the build, hence not much further on until today.....right back into it, engine is now ready to go in. I managed to fit my flywheel and used my home brew clutch alignment tool to fit the clutch assembly.....worked a treat.....when it came to trying to mate engine and box I discovered a water pipe fouling the upper engine bay diagonal so I intend to either shift the pipe or remove it and some corresponding pipework that actually won't be needed. sooooo will be back with the usual updates/piccies

|

|

#365

|

||||

|

||||

|

engine came back out for me to "minimise" cooling system.....turns out I could remove 10 water junctions and 4 hard tubes.....a lot of them were to keep the plenum warm in winter motoring....well they were the ones that were fouling so they have now gone and and flow route has been changed a little, that now done the engine went in without a hitch, apart from the customary wiggle wobble jiggle to get the gearbox primary shaft to engage the spigot bearing in the crankshaft.

Its in.....yaaaayy  |

|

#366

|

||||

|

||||

|

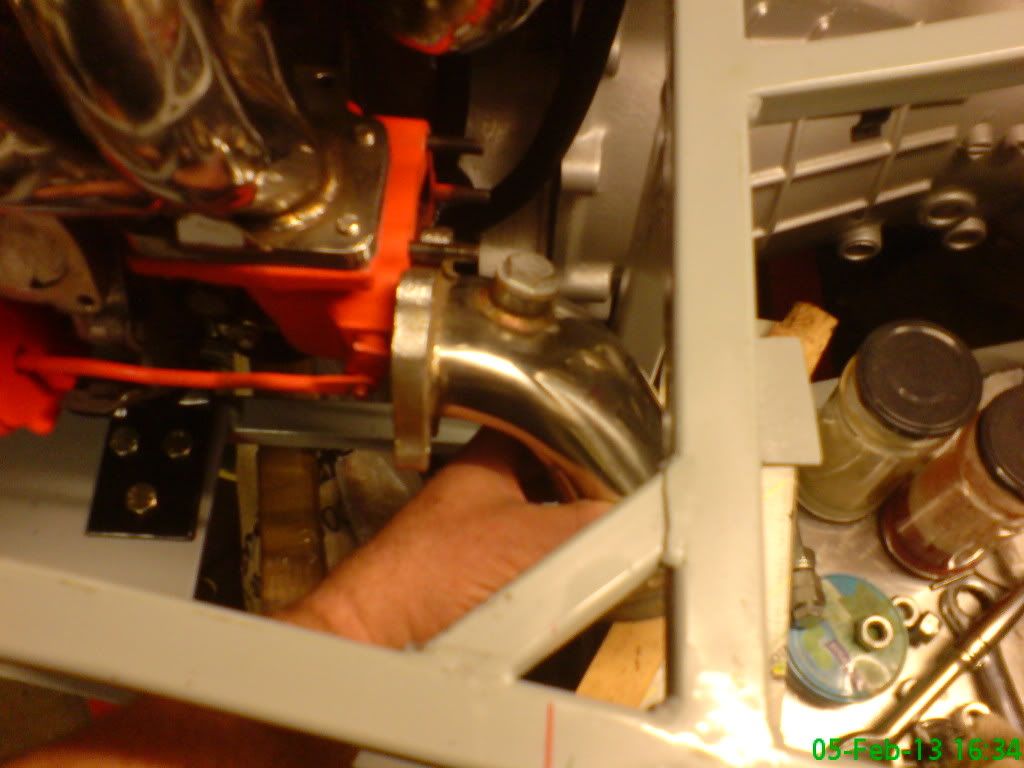

BOY am I gonna have a headache with this bugger

.....I knew it was tight and I was gonna have to re-fabricate the turbo down pipe but we are talking about a sod of a job and I don't want to cut bits out of the passenger well but I might have to....I can lose 9mm from the turbo studs as long as I recess the downpipe flange where the nuts fit. in fact I will probably lose the studs and use bolts instead, any thoughts peeps? .....I knew it was tight and I was gonna have to re-fabricate the turbo down pipe but we are talking about a sod of a job and I don't want to cut bits out of the passenger well but I might have to....I can lose 9mm from the turbo studs as long as I recess the downpipe flange where the nuts fit. in fact I will probably lose the studs and use bolts instead, any thoughts peeps? |

|

#367

|

||||

|

||||

|

Could you put the passenger footwell endplate on the inside of the footwell instead of the outside? That should give you an extra 25mm clearance.

__________________

1.8 Silvertop Zetec (ZX6R Carbs + Megajolt) + Type 9 My Build Blog: http://www.haynes.co.uk/forums/showthread.php?t=2736 - Last Update: 31st October 2020 Total Spent so far: Stopped counting

|

|

#368

|

|||

|

|||

|

Fabricate another flange and recess pipe into flange effectiveley shortening the distance between bulkhead and pipe and as Simon says (no pun intended

)put the plate on the inside. )put the plate on the inside.

__________________

Cost : Little as possible. Thanks : To those who by their generosity my build has progressed. Its a handmade sports car not a flaming kit car !!! If at first you dont succeed,avoid skydiving... No parachute require to freefall,only if you want to do it twice. |

|

#369

|

||||

|

||||

|

just one wee problem.....it is called U8 and it sits right in the middle so I cannot claw back the 25mm that you refer to.....the picture is a little misleading as I am holding the elbow towards me, check the turbo studs and direction I have marked where they point (either side of U8).....pipe was already inset into the flange Paul but I know what you are on about.....I will achieve the same result by cutting the diagonal line I drew on and re-weld it the flange is big enough to accept the greater length of the diagonal, maybe a little persuasion might be needed but the end result should leave me with the same sq area with maybe a very slight decrease in escape velocity of the exhaust gas

|

|

#370

|

||||

|

||||

|

How about cutting the outlet flange off on the exhaust manifold, rotate it 10-20 degrees and weld it back up.

Easier than the cut and shut you have suggested and should get you past the upright? Cheers Stot Last edited by Stot : 7th February 2013 at 01:05 PM. |

|

| Thread Tools | |

| Display Modes | |

|

|