|

|

#1

|

|||

|

|||

|

hi all just bought the book read it twice (missus is already dreading the amount of money its going to cost!) just wondering if anyone has used an e30 as a donor and have they any plans/drawings for the e30 diff mounts and rear hubs? any help greatly appreciated! cheers, Andy.

|

|

#2

|

||||

|

||||

|

Hi & welcome to the forum oh big namesake of mine

sorry i don,t have the answers to your questions tho i,m sure someone will come along with some info. cheers andy ( handyandy)   |

|

#3

|

|||

|

|||

|

Welcome to the nuthatch, It has been posted here before about using BMW running gear ie diff etc and I think the opinion was that using the rear suspension was out and fitting the diff etc was a pain too. The engine and box could be used to good effect and again this is on the forum with pics of a build but I cant remember who but someone will, I have a damaged 318 IS compact in the garage and am considering it for engine and box.

Good luck |

|

#4

|

||||

|

||||

|

Hi welome to the forum Big Andy.

I believe our mighty leader, Chris has made a few posts about the beemer running gear.  I am sure Chris will be along shortly, in the meantime have a good poke around the forum.

__________________

I am not a complete idiot...........Some of the parts are missing !! Ronnie  www.roadster-builders.co.uk |

|

#5

|

|||

|

|||

|

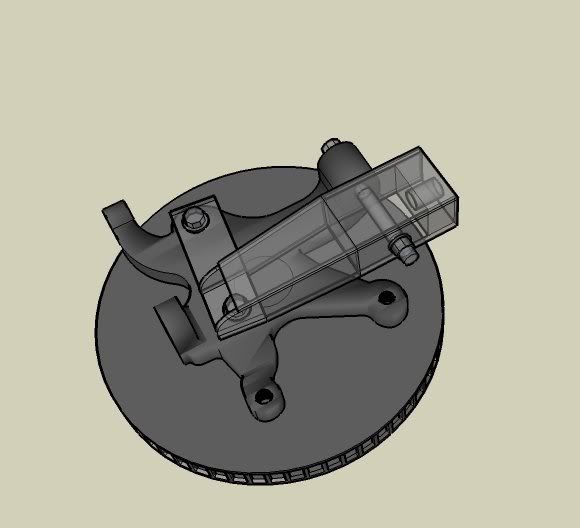

I've looked at the BMW E36 bits, the E30 bits are broadly similar.

The rear suspension will require a bearing housing to be made to take the BMW bearings and to fix to an upright similar to the Sierra one, as the BMW set up is unusable. The diff is quite big but can be squeezed in, and the same applies to the engine and gearbox, using mods similar to the MT75 ones. The front hub isn't tall enough to be used alone and requires a fabrication like this  which is bolted to the existing strut mountings. Hope this helps Cheers Chris  |

|

#6

|

|||

|

|||

|

cheers Chris, might see if i can source sierra rear hubs and drive shafts splice them with the bmw shafts and use the rest of the bmw running gear now to start sourcing some tube.....

Andy. |

|

#7

|

|||

|

|||

|

Hi Andy, we used as a donor 318ti, u can see the pictures here http://picasaweb.google.com/Longerr82/Project7 if any questions jsut ask, I"ll translate it to my father who has done the build

Last edited by Longerr : 18th May 2009 at 10:30 AM. |

|

#8

|

|||

|

|||

|

Andy, if you can. I would try and use the BMW rear end.

It's easy to get hubs with discs, or abs etc and as the rear carriers are fabricated it should be possible to fit them. It seems like it would be easiest to use sierra front uprights though. i'm not sure i'd fancy the adapter doodahs bolted to the back of the BM hubs. Mind you they would look nice machined out of billet Alloy. Cheers Chris Last edited by Chris_ : 20th May 2009 at 11:19 PM. |

|

#9

|

|||

|

|||

|

Theres quite a few people worldwide who are interested in using BMW parts some specific drawings and measurements (perhaps as an ANNEX to the book) and stickied on the forum might be good.

.......please  |

|

#10

|

|||

|

|||

|

Quote:

Bob. |

|

| Thread Tools | |

| Display Modes | |

|

|