|

|

#31

|

||||

|

||||

|

Just for you mike here are some of the pictures you asked about.

Like you said. Take core plug out of head & fit FWD thermostat housing. Manifold flange for bike carbs covers over the original water outlet, and I have fitted the sensor for the Acewell dash in the same position. You may notice in the first picture that I dog legged the chassis rail around the housing.

__________________

http://s831.photobucket.com/user/dav...ter%20Pictures OTR 01/05/14 - 1.6 CVH, Type 9, Bike Carbs, Megajolt Last edited by davedew : 18th October 2017 at 12:46 PM. |

|

#32

|

|||

|

|||

|

Thanks dave.

Thats how I'm doing it, I've tried to notch a bit out of the chassis rail and added a peice behind to add strength back, I wont know if the notch will work untils the engines in an revved up under load, as I've got the extra bit already in I can always cut the orginal rail out if it fouls, What carbs are you using? Where did you get the manifold plate from? Is there a cover for the part above the old water outlet (not sure what it is two bolts)

__________________

Build Cost so far £xxx (Given up adding it up) - She Starts!! Build Thread Here: http://www.haynes.co.uk/forums/showthread.php?t=5501 |

|

#33

|

||||

|

||||

|

Mike,

This is where work comes in handy. Being a CAD designer I drew up the manifold plate from a gasket & we have a CNC flame cutting machine at work so I cut it myself. The carbs are GSXR 600 carbs with a TPS. The manifold has been remade since this picture. No matter how hard I tried the carbs kept falling out of the silicon hoses so I bought the proper inlet rubbers. I then had the manifold skimmed on our mill at work to get it perfectly flat both sides. The cover you mention is where the fuel pump should be, but my engine started out as a CFI engine so had no fuel pump fitted, and that is how Ford blank the hole in the head. Hope that helps, any more questions feel free to ask.

__________________

http://s831.photobucket.com/user/dav...ter%20Pictures OTR 01/05/14 - 1.6 CVH, Type 9, Bike Carbs, Megajolt |

|

#34

|

|||

|

|||

|

Some folk are lucky to have machines to play with, must be a git having to "work" though when you want to get on and do your own stuff...

looking damn fine matey  |

|

#35

|

||||

|

||||

|

Good thing with it Mark is that if we had a quiet time, and the apprentice had nothing to do. "Just make this for me".

Got all the machined items need for the roadster & and few more besides made FOC  and help improve the skills of the work force and help improve the skills of the work force

__________________

http://s831.photobucket.com/user/dav...ter%20Pictures OTR 01/05/14 - 1.6 CVH, Type 9, Bike Carbs, Megajolt |

|

#36

|

|||

|

|||

|

I think theres a guy on lcb that will laser cut a plate for a good price!

Which way are you heading for the exhaust, that doesn't look like the standard sierra manfiold or down pipe, M

__________________

Build Cost so far £xxx (Given up adding it up) - She Starts!! Build Thread Here: http://www.haynes.co.uk/forums/showthread.php?t=5501 |

|

#37

|

||||

|

||||

|

Manifold is a series 2 Escort turbo manifold with an adapter plate between it and the head. Exhaust can is a Suzuki 1200 Bandit can with a custom stainless steel pipe between.

Again all made at work and polished by my own fair hand. The outlet of the can is rolled so will pass IVA but aims towards the rear arch. Providing the arch doesn't get damaged by the exhaust gas it should all be fine. The exhaust is actually quite quiet. It's the carbs that make all the noise when the engine is running.

__________________

http://s831.photobucket.com/user/dav...ter%20Pictures OTR 01/05/14 - 1.6 CVH, Type 9, Bike Carbs, Megajolt Last edited by davedew : 18th October 2017 at 12:46 PM. |

|

#38

|

|||

|

|||

|

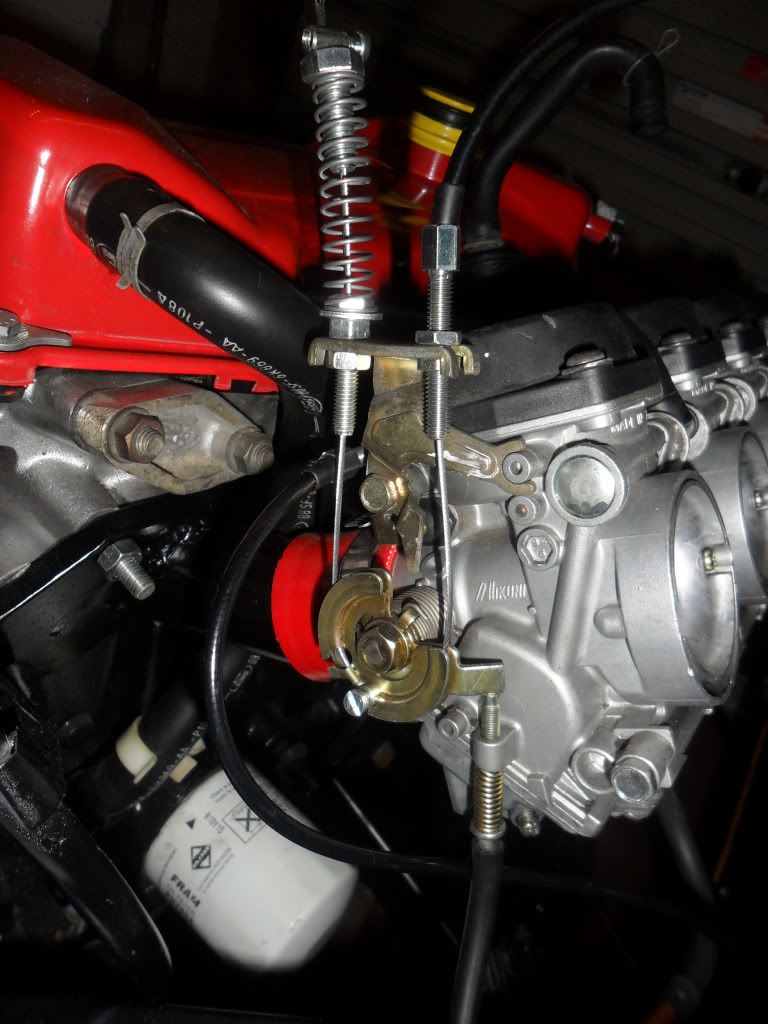

looking good but whats the deal with that odd push pull setup you have on the throttle cable?

the back cable was where the return cable would have been for the twist grip what is the deal with the spring and stuff? |

|

#39

|

||||

|

||||

|

Baz. I found that the throttle was lazy closing due to the extra weight of the pedal. By adding an additional spring the throttle closes more positively, and means the coil spring on the throttle spindle does not have to work as hard.

__________________

http://s831.photobucket.com/user/dav...ter%20Pictures OTR 01/05/14 - 1.6 CVH, Type 9, Bike Carbs, Megajolt |

|

#40

|

|||

|

|||

|

A squirt of wd40 down the inner of the throttle cable really helps too, mine closes like a rat trap!

|

|

| Thread Tools | |

| Display Modes | |

|

|