|

|

#141

|

||||

|

||||

|

Quote:

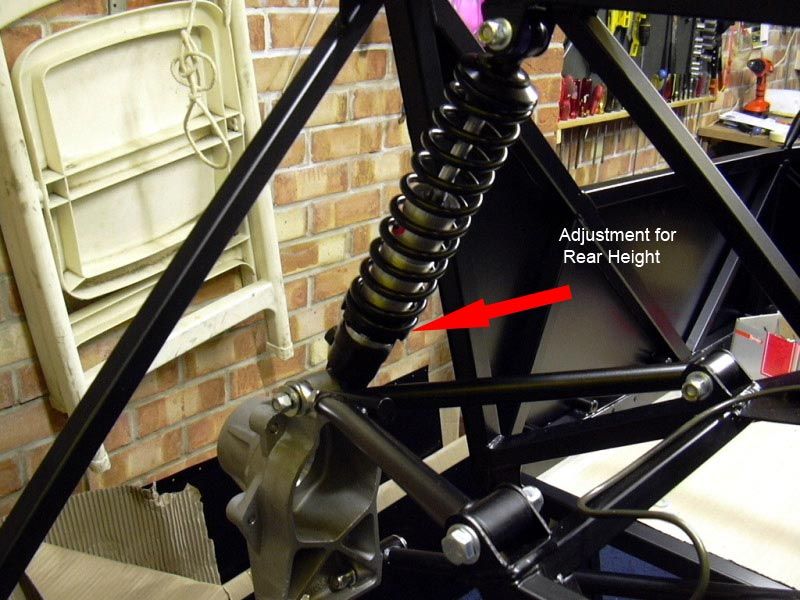

Sorry Steve will show all the welding posts from now on with an 18 certificate ......  Trust me there's a lot of better of welders on this forum than what I can do.... Trust me there's a lot of better of welders on this forum than what I can do.... Yeah I can't wait to see what it turns out like too as I'm making it up as I go along now....LOL Well here's a photo of the finished adjuster painted and in place...  Just got to add a couple of washers and a nylock to finish it off and it's done. Well I guess it's the wiring loom next and it's routing which I'm not looking forward to. Bye for now....Johno |

|

#142

|

||||

|

||||

|

Quote:

Well I like doing things the hard way..... At least i can say I made that (unless it fails and it's somebody else's fault)  will see how it works out  Johno |

|

#143

|

||||

|

||||

|

Quote:

It would appear Nathan at NTS had supplied me with a Sierra clutch pedal instead of an MX5 throttle pedal! I suspect it might be a bit late to get him to swap it now he's dissapeared off the face of the earth...  |

|

#144

|

||||

|

||||

|

Hi John,

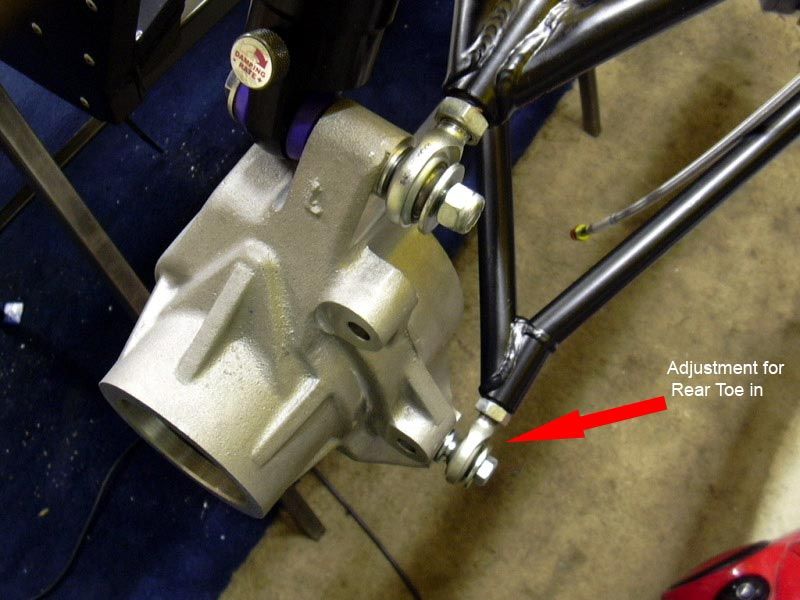

Glad to hear you found the problem...  I don't have the book with me but I guess the clutch pedal is shorter below the pivot bush? Should be an easy fix them as long as the guide tube through the pedal box still lines up with new position of the throttle connection. I've not done too much on the car lately. I've tried to spend some time with the kids whilst they're on holiday. I have drawn up an alteration to my current rear top wishbone. The lower mount for the shock is now above the yoke. I'm hoping this will put less stress on the adjuster. It's now similar to the Sierra setup in configuration. The position of the lower shock mount is 25mm longer than Saturns plans.  Also when the car is at ride height the shock and top upright pivots are all in line as you can see in this drawing.  This means I've just got to modify my yoke and i guess the shock will need to be 25mm longer..?? What I am trying to acheive by doing this is to use the lower adjusters on the bottom wishbone for "Toe in and out" and also track width. The top will be purely for "Camber" adjustment as I can do this in situ without removing parts. I should be able to get fine adjustment because of the fine pitch thread of the bolt. Does anybody see a problem with this?? as it's only on paper yet. Thanks Johno |

|

#145

|

|||

|

|||

|

I would say thats a sensible mod, You are taking a lot of strain off that top adjuster.

I dont suppose moving the spring outboard like that will foul the inset of the wheel rim on the mazda set up would it? I dont suppose moving the spring outboard like that will foul the inset of the wheel rim on the mazda set up would it?Bob

__________________

When The Results Disagree With The Theory: Believe The Results And Invent A New Theory If I had two brains I,d still be a halfwit The cave http://s1116.photobucket.com/user/my...deshow/mancave The build http://www.haynes.co.uk/forums/showthread.php?t=12669 |

|

#146

|

||||

|

||||

|

Quote:

I'm glad you think it's a step forward. As you said in a previous post it had flaws.  I'm hoping the bolt now will be OK. I don't know if you have seen my previous post but I modified my design of the yoke and adjuster. It's now an 8.8 grade bolt with the head cut off and fine pitch threads both ends with the shank of the bolt in the body of the bush. The bolt was chamfered for welding and and a threaded collar screwed onto the threads before welding. The bolt was welded to the yoke and then the collar was screwed upto the yoke and only welded to the yolk and not the bolt. My thinking was that this would not put stress directly on the weld between the bolt and yoke as the collar would help transfer some of the stress further along the bolt. Also there is minimum bolt length between the yoke and the bush. Sorry to bore you all...  I believe the clearance between the wheel rim and shock mount should be fine but as of yet I haven't checked this on the car. Looking at this photo it should be fine..  I'm not sure but doesn't the Sierra rear top wishbone have a similar setup in reference to welding a bolt to the bush..? (books at work). Also I'm sure I've seen a picture of a yoke welded to a bolt in the book for use on different donors. Well thanks for the input Robo I always appreciate advice from you guys. Johno |

|

#147

|

|||

|

|||

|

Westfield bring their shock straight off the top of the rear hub

The thread thing makes me nervous because a friend of mine built a v8 rover westie and the top rose joint sheered of. Westfields answer was to send him a better quality unit. Kin great when it could have killed him.I was in that car at break neck speeds the day before.It was not the one with the arrow that failed it was the top one  So thats what makes me anti anything with a thread on it being in sheer. Thats why I will be doing the same as your lower wishbones but top and bottom on all four corners. All those are just under compression or stretch which would make me a happy bunny. So thats what makes me anti anything with a thread on it being in sheer. Thats why I will be doing the same as your lower wishbones but top and bottom on all four corners. All those are just under compression or stretch which would make me a happy bunny.  Bob

__________________

When The Results Disagree With The Theory: Believe The Results And Invent A New Theory If I had two brains I,d still be a halfwit The cave http://s1116.photobucket.com/user/my...deshow/mancave The build http://www.haynes.co.uk/forums/showthread.php?t=12669 Last edited by robo : 14th September 2012 at 08:33 PM. |

|

#148

|

||||

|

||||

|

Ooooooo scary...

Wouldn't like to be in that when that gave way (brown trouser time comes to mind). So if I'm reading this right Westfield do not always use "Top of the range parts" in areas of their build. Worrying that especially in such a critical area.  I read in Keith Tanners build the company that supplied his chassis also supplied lesser quality parts and suffered suspension problems later on. Now you told me about that failure on your friends car I'm considering rethinking my rear top wishbone (currently MK5 I believe...LOL). If I do it will consist of inboard "Heim" adjusters and the shock still above the top upright (this time gonna ask for your opinions before fab).   Unfortuneatly it's too late for my front lower wishbones (redisgned them and fabbed them...ohhh).  I chose to make new lower wishbones to give me clearance for my steering rack extensions when on full droop. Kept the pivot and shock mount points the same just lowered the tubes or "A Arms" (tryin to make "Old Jag Guy" feel at home).... Front tops are redisgned on paper but not fabbed yet. After reading "Alga's" post on "Self centrering" I'm not sure if I should move the threaded adjuster to the rear of the car more? I've designed them so they can be adjustable without removing the top ball joint from the upright. Will post a picture when happy with the design. Johno |

|

#149

|

||||

|

||||

|

Bloody hell johno, its just taken me an hour to catch up on your build diary. You certainly have made progress and its looking better than ever! Love all the modifications, it wont be reconisable as a "haynes" soon!!

Stunning mate keep it up. Skov, Just stuck a pedal plate/tube/crush tube in a jiffy bag, cant beleive i did that aswell. I dont have access to a welder at the moment as someones got mine so i havent welded it.

__________________

A few build photos... www.photobucket.com/ntsengineering |

|

#150

|

|||

|

|||

|

amazing work! Wish someone made fully adjustable wishbones for the standard Roadster's that would save me a heap of trouble with getting my setup done.

|

|

| Thread Tools | |

| Display Modes | |

|

|