|

|

|

|

#1

|

||||

|

||||

|

couple of shots of in situ looking as if you were lying on your back underneath the car, going to be taken off and painted today then straight back on.

|

|

#2

|

|||

|

|||

|

Wow that is a bit tight! What tunnel did you go for? I decided on the MT75 and has give me loads of room. So much i can probably get away with the larger skyline gearbox if needed. I have to find myself a slave cylinder but that has given me a great idea mind if i copy it? as the ones for my box are around £90

|

|

#3

|

||||

|

||||

|

yeah go ahead Alex ...break a leg dude

....I always think, if it expensive is there a generic 3rd party item that will do the same job, and if that is too expensive then make it, if that does not work ........just sit down and cry ....I always think, if it expensive is there a generic 3rd party item that will do the same job, and if that is too expensive then make it, if that does not work ........just sit down and cry I chose the type 9 tunnel as the dimensions of the two boxes were similar but I placed a lot of emphasis on getting the hand to gearstick near perfect .....the cost was tight spaces in and around the gearbox area.....but hey it has not defeated me as of yet. Last edited by K4KEV : 13th February 2013 at 09:16 PM. |

|

#4

|

|||

|

|||

|

Couple of things kev, First on is the ratio of master boresize vs slave boresize. The last car i converted to hydraulic clutch was a total brain ache, I had about 6 inches of pedal travel (if i wanted to keep the pedals all at the same height at rest) and struggled to find the correct ratio of pedal movement vs clutch arm movement while maintaining a clutch that was not to heavy or to light . Or one that was so light it never released the clutch and one that was to heavy to be practical for driving. Got there in the end but not after going through a dozen different combos of bore sizes. Next thing is to check that the torque movement of the lump under load wont get that slave rubbing and buzzing on the chassis. Looks like you could get a rizla trapped in there

Just thoughts Bob Edit. dont trust that plastic waste pipe kev the stuff age hardens and splits.

__________________

When The Results Disagree With The Theory: Believe The Results And Invent A New Theory If I had two brains I,d still be a halfwit The cave http://s1116.photobucket.com/user/my...deshow/mancave The build http://www.haynes.co.uk/forums/showthread.php?t=12669 Last edited by robo : 14th February 2013 at 08:39 AM. |

|

#5

|

|||

|

|||

|

There is no stopping the Man !

__________________

Cost : Little as possible. Thanks : To those who by their generosity my build has progressed. Its a handmade sports car not a flaming kit car !!! If at first you dont succeed,avoid skydiving... No parachute require to freefall,only if you want to do it twice. |

|

#6

|

||||

|

||||

|

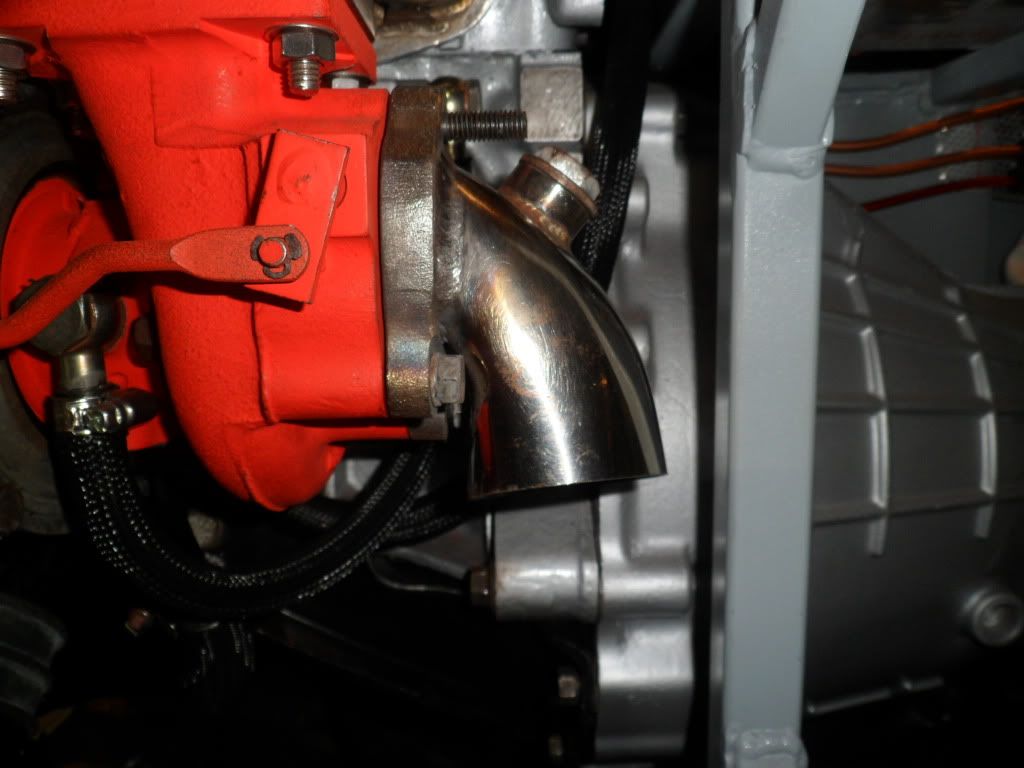

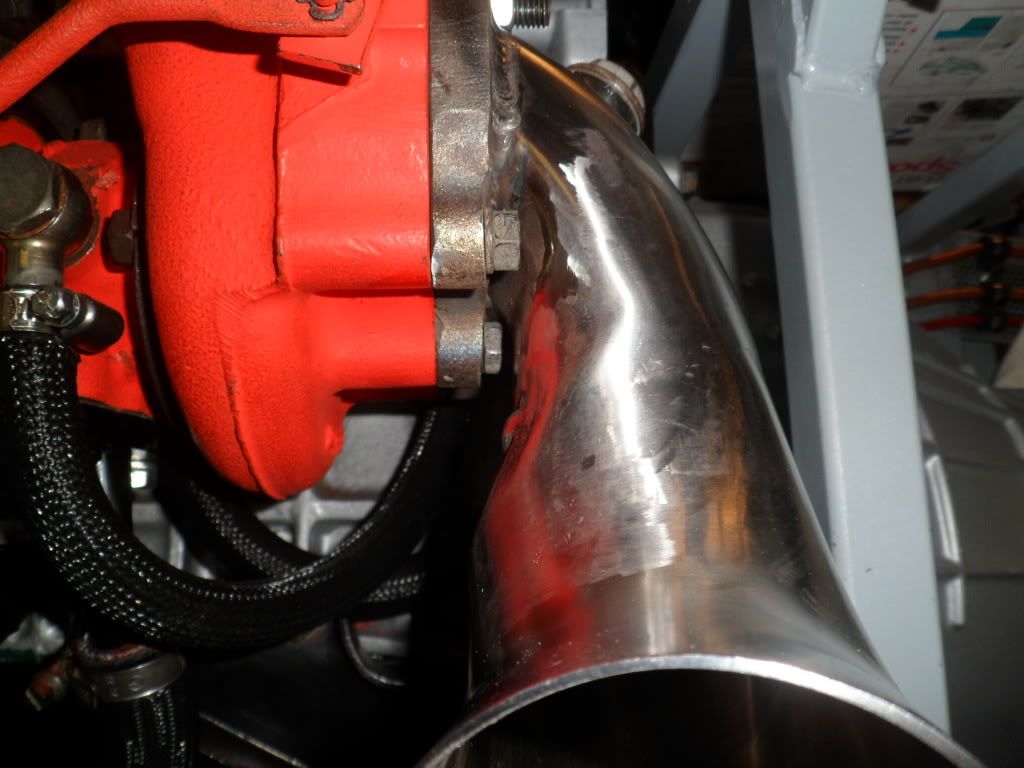

Me thinks I will cross that bridge when I get to it Bob but thanks for the heads up on it....my other headache is now solved, the turbo elbow had a wedge cut out of it and I had a bash at tigging stainless steel, I found it similar to ally except for the size of the arc which can be tiny. So now I am looking at welding on a 90 degree bend to bring it out of the side panel close to the bottom.

Here is my re-fabbed turbo elbow and first time tigging with stainless   |

|

#7

|

||||

|

||||

|

Exhaust is now coming together and I have learnt a lot about tigging stainless, and it aint as easy as I first thought.....got my 90 degree bend on and will soon fit and weld on a 3 hole flange to fit the outer exhaust pipe and silencer.....one picture is of me just offering the outer pipe up to check any clearance issues and none so far.

cut and welded up  looking from inside the car  these two lower bolt are t*ats to get at but do-able  and what it should look like  |

|

| Thread Tools | |

| Display Modes | |

|

|