|

|

|

|

#1

|

||||

|

||||

__________________

You only get a woosh with a dump valve Build Thread Man Cave Mantiques Cecil Street Auto Repairs Garage Carlisle Build Cost £4181.65 - Last - Wheel Cylinders |

|

#2

|

|||

|

|||

|

Has anyone used self tappings screws instead of rivets?.

Is there any reason why self tappers can't be used?. I was thinking of using them cheaper than rivnuts and could be removed afterwards if required. Regards Mick. |

|

#3

|

||||

|

||||

|

I would worry about them rattling loose, especially for the floor. There is no reason to remove the floor, so they provide no benefit there. You can use them for interior panels, but rivnuts seem like a sounder choice to me. Although they are pretty expensive and time-consuming to install.

__________________

Albert Haynes Roadster FAQ | Haynes Builder Locations Gallery, build thread in Lithuanian / via Google Translate. |

|

#4

|

||||

|

||||

|

Hi,

Thanks to all of you for the replies and very useful informations. I now have a very nice smooth black powder coated chassis, and also received the body kit from Equinox. As it has been said here before, the quality is very good. So, I think I will go for 3mm rivets for the floor, 50mm spacing, same for the trans side panels and back seat panel. And, I don't look forward to this, but I will fit all the body kit elements with rivnuts, as most of you say that it has to be easily removable. As well as the top gearbox and propshaft covers. Question: for the floor, should I use steel rivets (aluminium will be too weak?) I'm sure I will have further questions when I start  Thank you very much.

__________________

Sylvain Pictures of my completed Roadster https://www.flickr.com/photos/994983...7646799525542/ Build blog: http://vouchtroadster.blogspot.se/ https://caferacer-kawa-gpz-zx550.blogspot.com/ |

|

#5

|

||||

|

||||

|

I would worry about steel rivets rusting as they aren't painted etc. Aluminium rivets are plenty strong enough, they are used in planes! Make sure you use closed end rivets

I don't like rivnuts, they have a horrible tendency of spinning with the bolt still in them  I ended up tacking the rivnuts to my chassis where they hold the nosecone on. The only other body part held on with them is the scuttle.

__________________

http://www.facebook.com/EquinoxProducts http://www.haynes.co.uk/forums/showthread.php?t=13110 - Z20LET into a Roadster http://s775.photobucket.com/user/ben...?sort=6&page=1 |

|

#6

|

|||

|

|||

|

If you saw how planes are put together with rivets you would not get in one but I still do,need help obviously !

__________________

Cost : Little as possible. Thanks : To those who by their generosity my build has progressed. Its a handmade sports car not a flaming kit car !!! If at first you dont succeed,avoid skydiving... No parachute require to freefall,only if you want to do it twice. |

|

#7

|

||||

|

||||

|

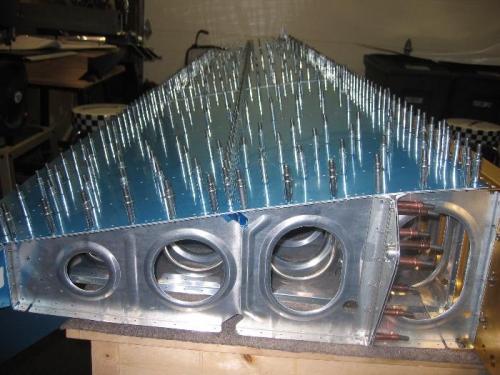

Something along the lines of this?

|

|

#8

|

||||

|

||||

|

Quote:

Also, I installed all of them without the special tool. I used a long M6 bolt with a nut on it, some washers, and a steel strip with a hole in it. I would thread the nut, washers, plate and rivnut on the bolt, insert the rivnut into its hole, clamp the plate to the chassis, then tighten the nut holding the bolt steady. The thread of 8.8 bolts and nuts would hold for installing 3-4 rivnuts before stripping, but that's ok. A stronger bolt would probably help.

__________________

Albert Haynes Roadster FAQ | Haynes Builder Locations Gallery, build thread in Lithuanian / via Google Translate. |

|

#9

|

|||

|

|||

|

Exactly Steve cleco heaven,but they use proper "rivets" .

__________________

Cost : Little as possible. Thanks : To those who by their generosity my build has progressed. Its a handmade sports car not a flaming kit car !!! If at first you dont succeed,avoid skydiving... No parachute require to freefall,only if you want to do it twice. Last edited by flyerncle : 2nd March 2014 at 09:47 AM. Reason: Cant spell "Cleco" |

|

#10

|

|||

|

|||

|

Quote:

I'm inclined to do similar to you, how many rivnuts did you use for the side panels. And did you drill out your 3mm floor (I have 3mm alu for the floor too) to fit the rivnuts flush with the floor panel? I had a look at your blog but my French is not good enough!!!

__________________

http://meandthekitcar.wordpress.com/ |

|

| Thread Tools | |

| Display Modes | |

|

|