|

|

|

|

#1

|

||||

|

||||

|

Ross you want the input and output flange to be as close to parallel as you can to prevent any vibration. When setting the height/offset of the engine you just need to make sure you don't go above 7 deg on each universal joint otherwise you run the risk of shortening the lifespan of the bearings. The smaller the angle the better though.

It's not the be all and end all if they aren't parallel/coaxial and you end up running different angles on both UJ's, it will just introduce more vibration into the system which essentially being a race car you won't really notice. If you were designing a tin top designed to cruise along the motorway at high speed you really don't want to feel that vibration. If you have a look at the shaft drive Triumphs you will see that only has 1 UJ meaning there isn't a second UJ to cancel out the speed variation and therefore the vibration in the system. And the rear wheel pivots the angle of the joint changes meaning the vibration in the system increases. So don't get too hung up on trying to get it spot on.

__________________

1.8 Silvertop Zetec (ZX6R Carbs + Megajolt) + Type 9 My Build Blog: http://www.haynes.co.uk/forums/showthread.php?t=2736 - Last Update: 31st October 2020 Total Spent so far: Stopped counting

|

|

#2

|

|||

|

|||

|

Quote:

|

|

#3

|

|||

|

|||

|

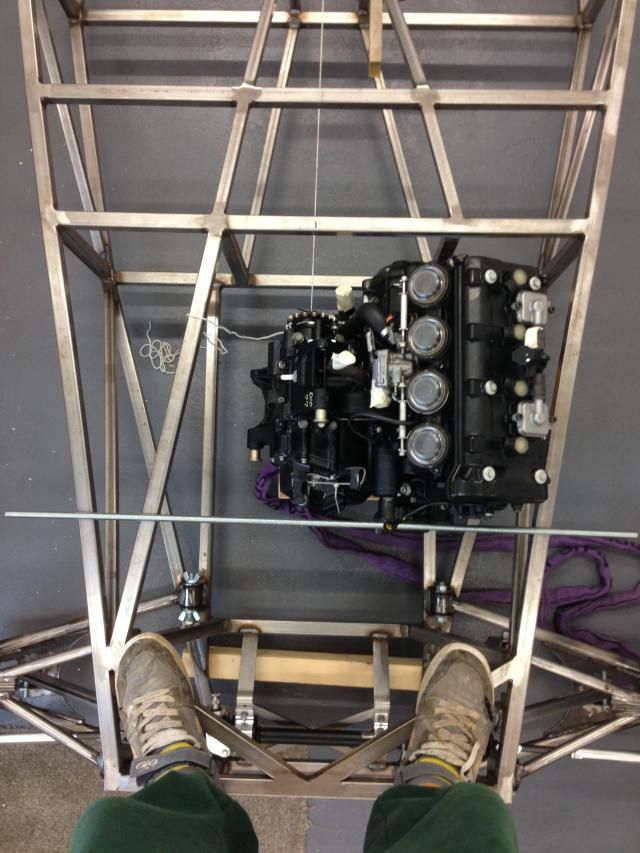

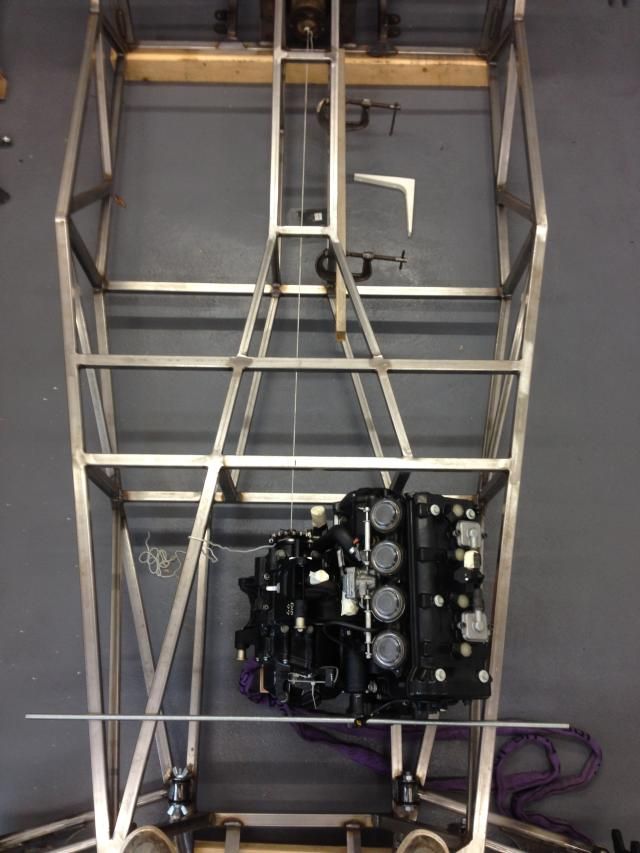

Just been looking at engine position and I'm sort of happy with this current position

Running the engine dead inline it seems to put the output shaft in a good position If I turn the engine so it's parallel to the outer chassis rail it just skews the output shaft but doesn't improve the position for the prop And from what I've read it's better for the flanges to be parallel     In this position the total prop length would be 1460mm but I could move the engine back 50mm if I moved the passenger footwell upright back I have strung a ling between and it's at an angle from the horizontal of about 4 deg, I take it I will still need a 2 piece prop with a centre bearing and a slight kink in the centre so the UJ's aren't running straight |

|

#4

|

|||

|

|||

|

|

|

#5

|

|||

|

|||

|

Argument was about angle of u/j's in the prop but you would need a center bearing anyway.

__________________

Cost : Little as possible. Thanks : To those who by their generosity my build has progressed. Its a handmade sports car not a flaming kit car !!! If at first you dont succeed,avoid skydiving... No parachute require to freefall,only if you want to do it twice. |

|

#6

|

|||

|

|||

|

Sorry I'm confused, what argument?

|

|

#7

|

||||

|

||||

|

Ross you can just use a 2 UJ prop setup with the UJ's 90 degrees out of phase, no need for a centre bearing. You only tend to use a centre bearing when you have 3 UJ's in the proshaft as you need the centre bearing to support the centre UJ otherwise it would be free move in free space.

__________________

1.8 Silvertop Zetec (ZX6R Carbs + Megajolt) + Type 9 My Build Blog: http://www.haynes.co.uk/forums/showthread.php?t=2736 - Last Update: 31st October 2020 Total Spent so far: Stopped counting

|

|

#8

|

|||

|

|||

|

Quote:

|

|

#9

|

|||

|

|||

|

|

|

| Thread Tools | |

| Display Modes | |

|

|